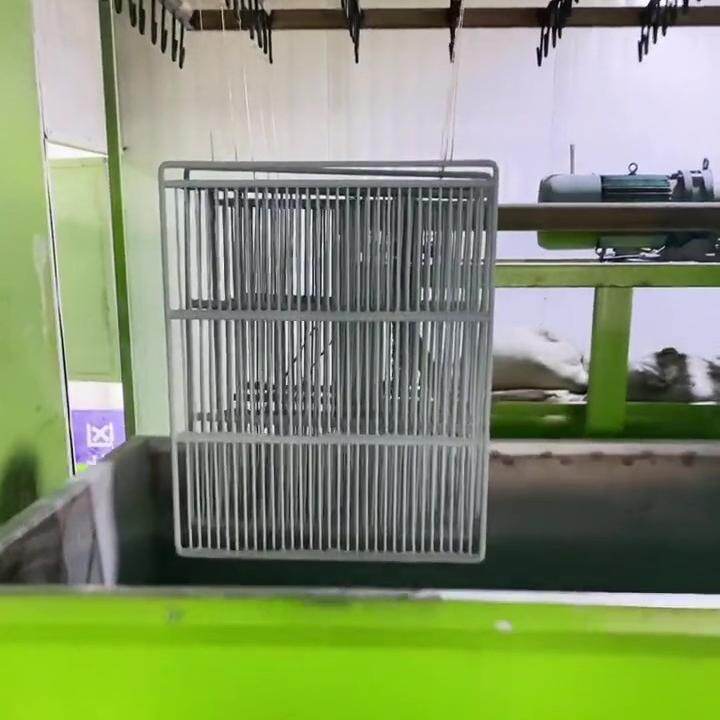

High Adhesion Uniform Coating Fluidized Bed Dip Powder Coating Equipment Versatile for Refrigerator Shelves and Metal Parts

Durable Coating Equipment for Complex Metal Workpieces Like Refrigerator Shelves

Refrigerator shelves face constant use, withstanding food spills, cleaning chemicals, and temperature changes. A low-quality coating leads to peeling, rust, and shortened product lifespan. Our High Adhesion Uniform Coating Fluidized Bed Dip Powder Coating Equipment is designed to deliver a dense, wear-resistant coating that adheres tightly to complex metal structures, ensuring refrigerator shelves maintain their performance and appearance for years.

This equipment excels at coating workpieces with intricate shapes, such as grid shelves with small gaps and grooves, which are hard to cover evenly with traditional methods. It also supports a wide range of metal materials, making it a versatile solution for multiple industries beyond refrigerator manufacturing.

Core Features for Superior Coating Quality

Uniform Coating for Complex Structures

The fluidized bed technology creates a stable, liquid-like powder layer that surrounds every part of the workpiece, including hard-to-reach areas like shelf grooves and edges. This ensures consistent coating thickness across the entire surface, eliminating thin spots or uneven coverage that cause premature coating failure.

High Adhesion & Durable Performance

The thermal adsorption coating process fuses powder particles to the preheated metal surface, forming a strong bond that resists peeling, scratching, and corrosion. The final coating is also resistant to common cleaning chemicals and temperature fluctuations, making it ideal for refrigerator interior use.

Versatile Compatibility with Metals & Workpieces

The equipment works with a variety of metal substrates, including steel, aluminum, and zinc alloys—the most common materials for refrigerator shelves. It also handles different workpiece sizes, from small hardware parts to extra-long refrigerator shelves, with customizable fluidized bed tank volumes (100L–500L standard, custom sizes available).

Technical Specifications

Parameter Category | Specification Details |

Certifications | ISO, CE, CCS, LR, ABS |

Coating Performance | High adhesion, uniform thickness, wear-resistant |

Compatible Materials | Steel, aluminum, zinc alloys |

Operation Modes | Automatic, Semi-automatic, Manual |

Heating Source | Electricity, Gas, Diesel (optional) |

Customization | Tank volume, equipment size, output |

After-sales Service | Lifetime technical support |

Transport Package | Wooden packaging |

MOQ | 1 Set |

Delivery Time | 20 days (based on customization) |

Working Principle: Thermal Adsorption for Strong Coating Bonding

1. Fluidized Bed Preparation: Controlled airflow suspends powder particles in a fluid layer, ensuring the powder is evenly distributed and ready for coating.

2. Workpiece Pre-treatment & Preheating: Refrigerator shelves are degreased and derusted to remove surface contaminants, then preheated to the optimal temperature to activate powder adhesion.

3. Dip Coating & Curing: Workpieces are immersed in the fluidized bed, where the hot metal melts the powder particles for tight adhesion. The coated shelves are then cured in an oven to form a dense, durable finish.

Key Advantages & Application Scenarios

Quality & Versatility Benefits

• Superior Coating Durability: High adhesion and wear resistance extend the lifespan of refrigerator shelves, reducing customer returns and warranty claims.

• Multi Industry Application: Beyond refrigerator manufacturing, the equipment can coat automotive chassis parts, hardware tool handles, home appliance brackets, and medical equipment accessories, helping you expand your product range.

Ideal for Manufacturers of All Scales

• Large Factories: Full-automatic mode ensures high-volume production with consistent quality, perfect for mass-market refrigerator brands.

• Small to Medium Enterprises: Semi-automatic or manual modes offer flexibility and low upfront costs, suitable for customized or niche production.

Whether you’re producing refrigerator shelves or other metal components, this fluidized bed dip powder coating equipment delivers the uniform, durable coatings your products need to stand out in the market.

Send Inquiry to This Supplier

You May Also Like

-

Standard Compliant Dip Mould Machine for Reliable ProductionNegotiableMOQ: 1 Set

-

Industrial-Grade Dip Mould Machine for Metal and Plastic ComponentsNegotiableMOQ: 1 Set

-

Dip Mould Machine With Technical Support and Free MaintenanceNegotiableMOQ: 1 Set

-

Automatic Dip Mould Machine With PLC Control for Precision CoatingNegotiableMOQ: 1 Set

-

Customizable Dip Mould Machine for Textile and Fabric CoatingNegotiableMOQ: 1 Set

-

Stainless Steel Dip Mould Machine for Industrial Rubber MoldingNegotiableMOQ: 1 Set

-

Dip Mould Machine With Temperature Control for Polymer ApplicationsNegotiableMOQ: 1 Set

-

High-Speed Dip Mould Machine for Ceramic and Glass CoatingNegotiableMOQ: 1 Set

-

PVC PE-Coated Zigzag Wiggle Wire Making Machine Line, Greenhouse Spring Wire Production EquipmentUS$ 2000 - 40000MOQ: 1 Set

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionUS$ 2000 - 40000MOQ: 1 Set