Industrial Dual Head BPG-200S Desiccant Insertion Equipment With Precise Metering

The Industrial Dual Head BPG-200S Desiccant Insertion Equipment revolutionizes moisture control in manufacturing with its precision engineering. This advanced system ensures exact desiccant dosing for critical applications where humidity control is paramount. Designed for high-volume production environments, it significantly reduces material waste while maintaining consistent product quality. The dual-head configuration doubles throughput capacity without compromising accuracy, making it an ideal solution for industries requiring reliable moisture prevention.

Core Technical Specifications:

Dosing Accuracy: ±0.5% tolerance for consistent performance

Throughput Capacity: Up to 120 units per minute (dual-head operation)

Material Compatibility: Works with various desiccant types including silica gel, clay, and molecular sieve

Adjustable Parameters: Precise control over fill weight, timing, and insertion depth

| Parameter | Specification |

|---|---|

| Machine Name | Desiccant Inserter (Dual Head) |

| Model | BPG-200S |

| Production Capacity | Up to 220 bottles/minute (Speed is adjustable and depends on packaging) |

| Applicable Bottle Diameter | ≤ 80 mm |

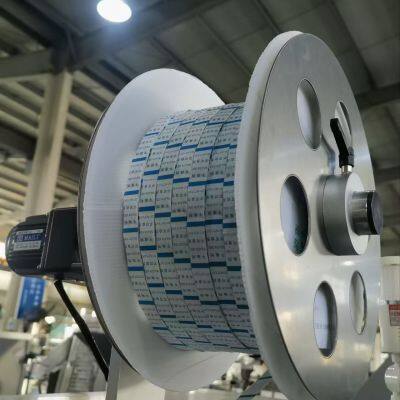

| Applicable Desiccant Roll | Outer Dia. ≤ 300mm, Inner Dia. = 75mm, Roll Thickness: 90-140mm |

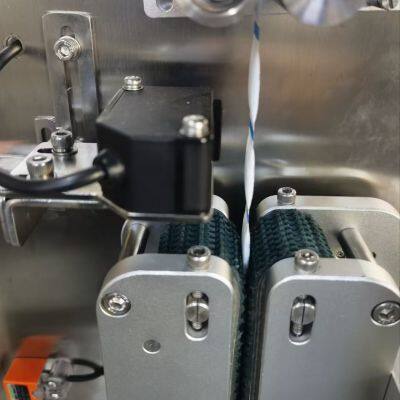

| Applicable Desiccant Pouch | Pouch Width ≤ 30mm (Length depends on bottle & dosage) |

| Voltage / Frequency | 220V / 50Hz |

| Total Power | 1.0 kW |

| Air Consumption | 5 L/Min |

| Dimensions (L×W×H) | 2000 × 750 × 2000 mm |

| Net Weight | 400 kg |

Operational Advantages:

Simultaneous dual-line processing increases production efficiency by 40% compared to single-head units

Self-diagnostic system alerts operators to potential maintenance needs before downtime occurs

Modular design allows for quick conversion between different container formats

Energy-saving mode reduces power consumption during idle periods

Industry Applications:

Pharmaceutical Packaging: Meets GMP standards with dust-free operation and validation support documentation

Electronics Manufacturing: Prevents corrosion in sensitive components during storage and shipping

Food Preservation: Food-grade material options available upon request

This precision desiccant insertion system delivers measurable ROI through reduced material costs and minimized production interruptions. The BPG-200S's robust construction ensures reliable performance in 24/7 operations, while its user-friendly interface simplifies staff training. With customizable options available for specific industry requirements, it provides a future-proof solution for evolving manufacturing needs.

Frequently Asked Questions:

What is the maximum container size this machine can handle?

The standard configuration accommodates containers up to 300mm in height and 150mm in diameter. Customizable tooling options are available for larger formats.Can it handle different desiccant types without recalibration?

The system includes preset profiles for common desiccant materials. Switching between materials requires simple menu selection with automatic parameter adjustment.What maintenance does the equipment require?

Daily cleaning of contact surfaces and monthly lubrication of moving parts. Full maintenance schedules are provided in the operation manual.Is the machine compatible with existing production lines?

Yes, it features standardized interfaces for integration with conveyor systems. Our engineers can provide integration support during installation.What safety features are included?

Dual emergency stop buttons, protective light curtains, and automatic shutdown during access door opening ensure operator safety.How is the dosing accuracy verified during operation?

Built-in load cells provide real-time weight verification, with automatic rejection of under/over-filled units.

Experience enhanced production efficiency and product protection with our precision-engineered desiccant insertion solution. Contact our engineering team today to discuss how the BPG-200S can optimize your moisture control processes. With comprehensive technical support and global service network, we ensure seamless implementation and ongoing operational excellence.

Send Inquiry to This Supplier

You May Also Like

-

BPS-D8 Automatic Vision Tablet Counter With CCD Camera System and ARM ProcessorNegotiableMOQ: 1 Set

-

Pharmaceutical Counting Equipment BPS-D8 Vision System for Pill & Vitamin QuantificationNegotiableMOQ: 1 Set

-

China Shark Industry BP-200 Fully Automatic Pharmaceutical Bottle Packaging Production LineNegotiableMOQ: 1 Set

-

Stainless Steel Rotary Turntable for Round, Squre BottlesNegotiableMOQ: 1 Set

-

High-speed Automatic Bottle Unscrambler Applied in Pharmaceutial, Health Food IndustryNegotiableMOQ: 1 Set

-

High-speed BPL-300 Huge Automatic Bottle Unscrambler Automatic Bottle Unscrambler Applied in Pharmaceutial, Health Food IndustryNegotiableMOQ: 1 Set

-

BPL-Z Rotary Bottle Unscrambler Machine GMP Standard for Pharmaceutical Packaging LineNegotiableMOQ: 1 Set

-

BPL-200 Automatic Bottle Unscrambler Machine for Pharmaceutical Packaging LineNegotiableMOQ: 1 Set

-

High-Speed Automatic Bottle Sorting Machine 200 BPM With PLC Control SystemNegotiableMOQ: 1 Set

-

Automatic Stainless Steel Rotary Bottle Collecting Table PLC Controlled Bottle Unscrambler With Overload Protection and Touch ScreenNegotiableMOQ: 1 Set