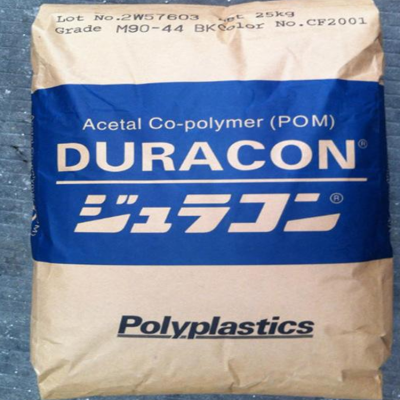

POM has a hardness, strength, and rigidity similar to metals, good fatigue resistance, and is rich in elasticity. In addition, it has good chemical resistance. POM has been widely used in electronic and electrical, mechanical, instrumentation, daily light industry, automotive, building materials, agriculture and other fields. POM, at a lower cost than many other engineering plastics, has traditionally dominated the market dominated by metals, such as replacing zinc, brass, aluminum, and steel to make many components. POM has gradually replaced POM in many new fields such as medical technology and sports equipment. POM can be processed using general thermoplastic molding methods such as injection molding, extrusion, blow molding, rotational molding, etc. Injection molding is the most important processing method, with a large shrinkage rate. The mold temperature should be higher, or annealed, or reinforced with materials.

Send Inquiry to This Supplier

You May Also Like

-

Halogen-free Flame-retardant PA66NegotiableMOQ: 25 Kilograms

-

EVA Foam Grade From Formosa Plastics, Model 7470MNegotiableMOQ: 25 Kilograms

-

Infrared Rays Can Penetrate PC MaterialsNegotiableMOQ: 25 Kilograms

-

PC Covestro Germany Model 2405NegotiableMOQ: 25 Kilograms

-

High-temperature-resistant PC 1803 Germany CovestroNegotiableMOQ: 25 Kilograms

-

German Covestro PC 6555 (flame-retardant Grade PC)NegotiableMOQ: 25 Kilograms

-

Medical Grade PC RX1805NegotiableMOQ: 25 Kilograms

-

UV Resistant PC 2407 CovestroNegotiableMOQ: 25 Kilograms

-

Food Grade PC 2856(Covestro)NegotiableMOQ: 25 Kilograms

-

Light Diffusion PCNegotiableMOQ: 25 Kilograms