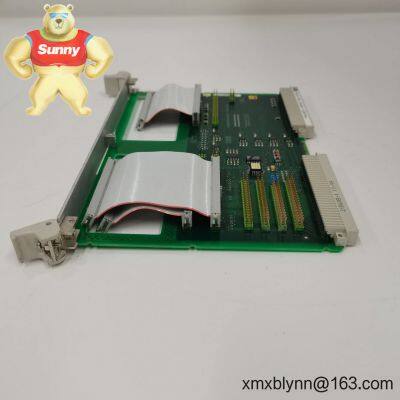

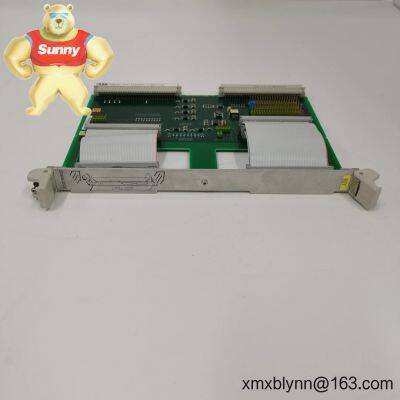

ABB 500TRM02 (1MRB150011R0001) – Transducer/Relay Module for Drive and Process Control Cabinets

The ABB 500TRM02, ordering code 1MRB150011R0001, is a plug-in transducer/relay module typically used within ABB 500-series control racks and drive/excitation cabinets. From my experience, it’s chosen when you need reliable signal conditioning and clean, isolated relay outputs in demanding environments. You’ll see it applied in motor control, turbine auxiliaries, and general industrial automation where stable, low-noise I/O is a must.

Signal conditioning for field inputs – Typically supports common analog standards (0–10 V, 4–20 mA) with filtering to reduce noise and drift.

Isolated relay/digital outputs – Provides galvanic isolation to protect upstream controllers and improve EMC robustness.

Backplane-powered – In many cases powered from the system rack (often 24 VDC nominal), minimizing cabinet wiring complexity.

Fast replacement design – Plug-in card architecture shortens downtime; swap-and-restore is usually straightforward with existing wiring.

Industrial temperature resilience – Designed for cabinet environments in most plants; stable performance across typical operating ranges.

ABB ecosystem compatibility – Pairs well with ABB 500-series controllers, power supply modules, and standard backplane interconnects.

| Brand / Model | ABB 500TRM02 (Ordering code: 1MRB150011R0001) |

| Power Requirements | Typically 24 VDC via rack/backplane supply (exact value per cabinet build) |

| Signal I/O Types | Analog inputs (e.g., 0–10 V / 4–20 mA) with isolation; relay/digital outputs for control and status |

| Communication Interfaces | Backplane connection to the controller; no external fieldbus on the module itself |

| Operating Temperature | Typically 0 to +55°C within a ventilated control cabinet |

| Dimensions & Weight | Compact plug-in module, typically under 0.5 kg; exact size depends on rack/card carrier |

| Installation Method | Plug-in to ABB 500-series rack/backplane; field wiring via terminal strips or backplane connectors |

Drives and Motors – Conditioning speed/feedback signals and driving interlock relays around ABB AC/DC drive systems.

Excitation & Turbine Auxiliaries – Reliable I/O handling in excitation cabinets and turbine accessory control, where isolation is key.

Process Automation – Interface between field instruments and the main controller in water, chemicals, and paper lines.

Material Handling – Conveyor, hoist, and crane panels that need clean handshaking signals and fault relay outputs.

Reliability – ABB modules tend to show consistent MTBF in dusty or warm cabinets when ventilation is adequate.

Compatibility – Fits the ABB 500-series ecosystem; minimizes rewiring compared to third-party boards.

Lifecycle Support – Spare part code 1MRB150011R0001 is commonly referenced in service lists, which simplifies sourcing.

Cost Control – Swap-in replacement reduces downtime and engineering hours versus redesigning I/O.

Customer note: “We had intermittent trips on a material feed line. Replacing the 500TRM02 stabilized the analog scaling and the nuisance alarms cleared. Took less than an hour, including checks.”

Cabinet environment – Install in an enclosed, ventilated panel; target ambient 0–55°C with humidity control and no corrosive gas.

Wiring – Keep analog lines shielded and grounded at a single point; route away from high-voltage or VFD output cables.

Rack/backplane – Seat the module firmly; verify backplane connector pins are clean. Power off before insertion or removal.

Safety – Lockout/Tagout the panel supply; discharge stored energy on drives before handling any module.

Routine checks – Inspect terminal torque, connector oxidation, and relay contact wear during scheduled shutdowns.

Calibration & updates – If your site procedures include analog scaling checks, verify yearly; keep controller firmware aligned with module revisions.

Certifications – CE compliant and manufactured under ISO 9001 quality systems; RoHS conformity is typical for current production.

UL/CSA – Many ABB control modules are UL Recognized; exact file depends on production batch. We can verify by serial/lot on request.

Warranty – Standard 12-month warranty from shipment for new units, subject to ABB policy and operating conditions.

The 500TRM02 is commonly paired with ABB 500-series power supply modules, the main controller rack/backplane, and standard terminal blocks used for field I/O. If you’re planning a like-for-like replacement, sharing your rack code and controller type helps confirm pinout and channel mapping before dispatch.

If you need a configuration check or a quick compatibility review (especially for mixed 500-series racks), send a cabinet photo and the existing module labels. It saves time and, in many cases, avoids a second site visit.

Send Inquiry to This Supplier

You May Also Like

-

ABB 5SHX1960L0001 — Control/Interface Module for Industrial DrivesNegotiableMOQ: 1 Combo

-

ABB 5SHX19L6010 — Soft Starter for Medium/Heavy-Duty Motor ControlNegotiableMOQ: 1 Combo

-

ABB 5SHX0845F0001 / 5SXE05-0151 — IGCT Power Module for Medium-/High-Power ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHX0860H0001 — Gate Turn-off Thyristor Module for High-Power ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHX1960L0001 — Drive Control / I/O Replacement Module (field Service Spare)NegotiableMOQ: 1 Combo

-

ABB 5SHX19L6010 — Compact Low‑Voltage Motor Soft Starter for Industrial DrivesNegotiableMOQ: 1 Combo

-

ABB 5SHX2645L0001 — IGCT Power Module for Medium‑Voltage ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHX3545L0016 / 3BHB020720R0002 — High‑Power IGCT Module for Industrial ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHY0660L0001 IGCT — High‑power IGCT Module for Medium/High‑Power ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHY3545L0001 — Asymmetric Thyristor IGCT for High-Power ConvertersNegotiableMOQ: 1 Combo