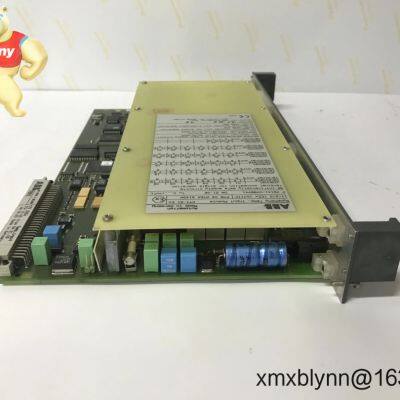

ABB 3BDH000741R1 CTI21-P – Pulse/Encoder Input Interface for ABB Control Systems

The ABB 3BDH000741R1 CTI21-P is a compact interface module designed for acquiring pulse and encoder-type signals into ABB automation platforms. From my experience, it’s typically used when you need reliable high‑speed count or frequency data from field devices—think turbine speed pick‑ups, flowmeter pulses, or incremental encoders—without re‑engineering the whole control cabinet.

You might notice that it fits naturally into existing ABB DCS/PLC architectures, which helps reduce wiring complexity and keeps commissioning time reasonable, especially on brownfield upgrades where downtime is tight.

Pulse and encoder signal capture – Designed to handle typical pulse/frequency inputs from speed sensors, flowmeters, and incremental encoders.

Backplane integration – Interfaces through the ABB system backplane, so you don’t need external protocol converters.

Noise‑robust design – In many cases, the module is used in cabinets near drives and motors; with proper shielding/grounding, it maintains stable counts in electrically noisy environments.

Status and diagnostics – Clear front indicators (typically LEDs) make field troubleshooting fast during commissioning or maintenance.

Configuration flexibility – Channel behavior is usually set in the controller engineering tool, making scaling and filtering straightforward.

Fits existing ABB ecosystems – Commonly deployed in ABB 800xA environments alongside mainstream ABB controllers, helping standardize spares and support.

Power generation – turbine speed pick‑ups and overspeed monitoring (secondary channels).

Water & wastewater – pulse output flowmeters for totalizer and rate calculations.

Metals, pulp & paper – line speed tracking via encoders on conveyors or winders.

Chemicals & oil/gas – batching skids using proximity pulses or meter proving inputs.

General factory automation – any panel that needs clean, timestamp‑friendly pulse counts into the ABB DCS/PLC.

Native ecosystem fit – Being an ABB module, it typically shortens engineering time and avoids compatibility surprises.

Lower lifecycle cost – Standardized spares, common tools, and ABB’s global support network reduce long‑term ownership costs.

Reliable performance – Designed for control cabinets near heavy equipment; with proper wiring practice, counts remain stable.

Scalable – Easy to add channels as systems grow, without extra converters or third‑party signal boxes.

- Install the CTI21-P on the designated ABB base/backplane inside an IEC-rated cabinet with adequate ventilation. Keep ambient below the typical 55 °C ceiling and allow space for air flow.

- Use shielded, twisted-pair signal cabling for pulse/encoder sources; ground the shield at one end (cabinet side) to minimize ground loops.

- Route low-level signal cables away from VFD outputs, soft-starter cables, and contactor bundles. Separation and proper earthing make a noticeable difference.

- Configure input scaling, debounce, and filtering in the ABB engineering tool. Validate counts against a handheld tach or a known pulse generator during commissioning.

- Routine maintenance is light: check terminal tightness, inspect shields/grounds, clean dust from the cabinet, and keep controller firmware and project files up to date.

Manufactured to ABB quality standards; CE compliance for industrial control equipment is typical for this series.

RoHS conformity is common for current revisions; UL or other regional marks may apply depending on the exact build.

Standard manufacturer warranty applies; extended service coverage is available through ABB service frameworks.

One thing I appreciate is how easily the CTI21-P drops into existing ABB cabinets. In one retrofit on a turbine water injection skid, we reused the existing encoder and simply adjusted the filtering in software—no external signal conditioner needed. On another site, we had intermittent counts until we re-terminated the shield correctly; after that, the diagnostics stayed clean for months. Little wiring details matter with pulse signals, and this module seems to reward good practice.

ABB controller families used in 800xA environments (e.g., AC 800M / AC 800F), depending on project architecture.

ABB system base/backplane units and cabinet accessories for DIN-rail or rack installation.

Shielded encoder or proximity sensor cables, cabinet EMC grounding kits, and labeling to keep maintenance straightforward.

Send Inquiry to This Supplier

You May Also Like

-

ABB 3BHB006716R0217 – Drive Power Module Assembly for Reliable Inverter PerformanceNegotiableMOQ: 1 Combo

-

ABB 3BHB007445P0001 (POS.A6033) – Position/feedback Interface Board for ABB Drive and Controller PlatformsNegotiableMOQ: 1 Combo

-

ABB 3BHB012961R0001 – OEM Drive Module/Board for Restoring Uptime in ABB Industrial DrivesNegotiableMOQ: 1 Combo

-

ABB 3BHB018104R0001 IGCT Module – High‑power Switching Element for Medium‑voltage Drives and ConvertersNegotiableMOQ: 1 Combo

-

ABB 3BHB026114R0001 IGCT – High‑power Press‑pack Device for Medium‑voltage Drives and ConvertersNegotiableMOQ: 1 Combo

-

ABB 3BHD000892R0461 IGCT – High‑reliability Press‑pack IGCT for Medium‑voltage Drive and Converter StacksNegotiableMOQ: 1 Combo

-

ABB 3BHE004573R0142 (UFC760BE142) – Digital Control Board for UNITROL Excitation and MV Drive ControlNegotiableMOQ: 1 Combo

-

ABB UFC789AE101 (3BHE014023R0101) – Reliable Rack-mounted Controller Board for ABB Industrial Automation SystemsNegotiableMOQ: 1 Combo

-

ABB 3BHE017628R0102 PPD115A102 – Pulse Pattern Driver Board for Medium-Voltage Drive ControlNegotiableMOQ: 1 Combo

-

ABB 3BHE014105R0001 + 5SHY3545L0020 5SHX26L4510 – Gate Unit and IGCT Pair for Medium-voltage Drives and ConvertersNegotiableMOQ: 1 Combo