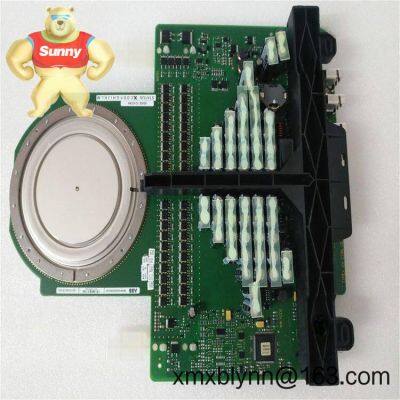

ABB 3BHB005171R0101 IGCT – Press-pack Power Device for Medium-voltage Drives and High-reliability Converters

The ABB 3BHB005171R0101 is an IGCT (Integrated Gate-Commutated Thyristor) assembly designed for demanding medium-voltage applications where high current handling, fast turn-off, and long service life matter. You’ll typically see this part used in ABB MV drives and power conversion systems where uptime and predictable thermal behavior are non-negotiable.

From my experience, maintenance teams choose this IGCT when they want press-pack robustness (fail-safe clamping, uniform current sharing) and a straightforward path to keep installed ABB assets running to spec.

IGCT turn-off capability – Combines the conduction efficiency of a thyristor with GTO-like controlled turn-off for reliable switching under high currents.

Press-pack construction – Metal-to-metal pressure contact helps with thermal cycling and typically provides a predictable end-of-life (short-circuit fail-safe behavior).

Low-inductance gate path – The integrated gate concept minimizes loop inductance, improving dv/dt handling and dynamic performance in fast-switching MV topologies.

Service-friendly – Designed for clamp-in replacement; in many cases this is a drop-in fit for designated ABB drive frames when matched to the correct gate unit.

Thermal stability – Press-pack devices typically share current well across parallel paths, supporting consistent thermal behavior under heavy load.

Traceability – Genuine ABB parts carry clear identification and traceable build data, which makes lifecycle and fleet management easier.

| Brand / Model | ABB 3BHB005171R0101 IGCT |

| Device Class | Integrated Gate-Commutated Thyristor (press-pack assembly) |

| Power Requirements | Semiconductor device (no internal power). Gate unit supply is provided by the matching ABB gate unit (commonly 24 VDC systems in ABB MV drives). |

| Dimensions & Weight | Press-pack disc form factor; size aligns with ABB IGCT family used in MV drives. Exact dimensions should be confirmed against the drive’s spare parts list. |

| Operating Temperature | Junction limits per ABB IGCT datasheet; cabinet ambient for MV drives typically 0–40 °C (site dependent). |

| Signal I/O Types | Gate drive via integrated gate path and ABB gate unit; status/triggering in many ABB systems is fiber-optic to the gate unit (device itself has no comms). |

| Communication Interfaces | Not applicable to the semiconductor device; interface resides on the gate unit/drive controller. |

| Installation Method | Clamped between heatsinks/cold plates with specified force and torque sequence; use matched ABB gate unit and snubber network as per drive manual. |

Note: The 3BHB005171R0101 part number is used within ABB assemblies; confirm compatibility with your drive type code (e.g., ACS medium-voltage families) and build list before ordering.

Application FieldsMedium-voltage drives (fans, pumps, compressors, kiln drives) where stable long-term switching and predictable thermal behavior are key.

FACTS and grid applications (STATCOM/SVC) that need fast transient response and high reliability.

Large rectifiers and cycloconverters in metals, mining, and marine propulsion.

Wind and test-bench converters where uptime and maintainability typically outweigh marginal efficiency gains.

A maintenance lead at a cement plant told me their ACS medium-voltage line returned to full load after a planned IGCT swap with this code; clamping and gate unit checks took under three hours with two techs.

Advantages & ValueReliability under stress – Press-pack devices tend to handle thermal cycling better than many plastic modules in similar MV roles.

Compatibility – Intended for ABB drive architectures that specify the 3BHB005171R0101 build; reduces risk during planned outages.

Operational continuity – Using the correct IGCT/gate unit pairing helps protect snubbers and commutation circuits, avoiding nuisance trips.

Total cost – In most cases, fewer unplanned stops and shorter replacement windows outweigh the device cost.

Technical backing – Documentation, torque/clamping data, and test procedures are well-established in ABB service literature.

Cabinet & environment – Install in a clean, dry cabinet with adequate ventilation or liquid cooling, following the drive’s thermal design. Keep dust and fibers away from press surfaces.

Clamping – Use the specified clamping force and torque pattern from ABB’s service manual. Surface flatness and cleanliness of the heatsink/cold plate are critical.

Wiring – Route the gate drive path per ABB guidance to minimize inductance. Verify fiber connections (if used) and polarity before energizing.

Safety – Lock out/tag out, discharge DC links, and observe HV clearances. Handle the device by its edges; avoid scratching the contact metallization.

Routine checks – Inspect clamping hardware torque, clean contact surfaces during overhauls, and verify gate unit health (self-checks, alarms). Replace snubbers if aging indicators appear.

Calibration/updates – Where applicable, load the gate unit firmware recommended for your drive revision; it seems to reduce nuisance triggering in some setups.

Manufactured under ISO 9001 quality systems (ABB semiconductor processes).

RoHS and REACH-compliant materials, as typically specified for ABB power semiconductors.

Used within CE/UL certified drive systems; the device itself is a component and not CE-marked standalone.

Standard manufacturer’s warranty terms apply when supplied new and unmodified (duration depends on procurement channel).

ABB gate unit for the matching IGCT voltage/current class (fiber-optic interface in many MV frames).

Snubber capacitor/resistor network specified for the drive topology.

Approved clamping hardware set and alignment tooling for press-pack installation.

Thermal interface materials compatible with press-pack surfaces (use as directed; many ABB assemblies rely on direct metal contact).

If you can share your drive type code and frame rating, I can double-check fitment for this exact part number and suggest the matching gate unit and snubber kit to streamline your outage plan.

Send Inquiry to This Supplier

You May Also Like

-

ABB 3BHB026114R0001 IGCT – High‑power Press‑pack Device for Medium‑voltage Drives and ConvertersNegotiableMOQ: 1 Combo

-

ABB 3BHD000892R0461 IGCT – High‑reliability Press‑pack IGCT for Medium‑voltage Drive and Converter StacksNegotiableMOQ: 1 Combo

-

ABB 3BHE004573R0142 (UFC760BE142) – Digital Control Board for UNITROL Excitation and MV Drive ControlNegotiableMOQ: 1 Combo

-

ABB UFC789AE101 (3BHE014023R0101) – Reliable Rack-mounted Controller Board for ABB Industrial Automation SystemsNegotiableMOQ: 1 Combo

-

ABB 3BHE017628R0102 PPD115A102 – Pulse Pattern Driver Board for Medium-Voltage Drive ControlNegotiableMOQ: 1 Combo

-

ABB 3BHE014105R0001 + 5SHY3545L0020 5SHX26L4510 – Gate Unit and IGCT Pair for Medium-voltage Drives and ConvertersNegotiableMOQ: 1 Combo

-

ABB 3BHE021951R0124 – OEM Control Board Module for ABB Industrial Drive and Control SystemsNegotiableMOQ: 1 Combo

-

ABB PPD113B03-26-100110 (3BHE023584R2634) – Control Board for ABB Drive and Excitation PlatformsNegotiableMOQ: 1 Combo

-

ABB 3BHE023584R1923 Control Board – Reliable Replacement Module for ABB Drive and Excitation PlatformsNegotiableMOQ: 1 Combo

-

ABB 3BHE023784R1010 – Control Board Module for Advanced Drive and Power Control SystemsNegotiableMOQ: 1 Combo