Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating Temperature

-30℃~60℃

Measurement accuracy

±0.5℃

Storage Temperature

-40℃~85℃

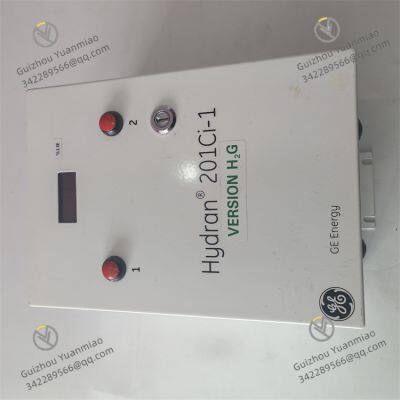

I. Product Overview

The GE ENERGY HYDRAN H201Ci-1 is a portable online monitoring device for insulating oil in electrical equipment, specifically designed for monitoring the insulation status of oil-filled electrical equipment such as transformers, reactors, and instrument transformers. Acting as a "health sentinel" for the safe operation of electrical equipment, it accurately assesses potential risks inside the equipment—including insulation aging, partial discharge, and overheating faults—by real-time collecting key parameters such as the concentration of dissolved gases (e.g., hydrogen, methane, ethane, ethylene, acetylene) in insulating oil, moisture content in oil, and oil temperature. It provides full-lifecycle condition monitoring and fault early warning services for oil-filled electrical equipment in power grids, power stations, and industrial enterprises, preventing sudden shutdowns or safety accidents caused by equipment insulation failure.

In the fields of power systems and industrial electrical engineering, oil-filled electrical equipment is a core asset ensuring energy transmission and production power supply, and its insulation status directly determines the reliability of equipment operation. With the characteristics of "portable installation + real-time monitoring + intelligent diagnosis", the HYDRAN H201Ci-1 is not only suitable for long-term monitoring of large transformers in power grid substations but also can be flexibly deployed in small and medium-sized oil-filled equipment of industrial enterprises (e.g., workshop reactors). Especially in high-voltage and high-load operation scenarios, it can detect equipment insulation hazards 3-6 months in advance, providing data support for operation and maintenance personnel to formulate preventive maintenance plans, and significantly reducing equipment operation and maintenance costs as well as fault risks.

II. Technical Specifications and Performance

Monitoring Parameters and Accuracy

2. Electrical and Communication Characteristics

Power Supply Requirements: Wide-voltage power supply design, supporting 100-240V AC (50/60Hz) or 24V DC (±10%), maximum power consumption ≤15W, suitable for power supply needs in different scenarios (e.g., AC power supply in substations, DC power supply in industrial workshops);

Communication Interfaces: Supports multi-protocol communication, including RS485 (Modbus RTU), Ethernet (Modbus TCP/IP), and 4G LTE (optional); data transmission rate: RS485 9600-115200bps, Ethernet 10/100Mbps; enables local data reading and remote cloud monitoring (e.g., access to the GE Predix industrial cloud platform);

Data Storage: Built-in 8GB industrial-grade SD card, supporting local storage of ≥3 years of historical data (at a sampling frequency of 5 minutes per sample); data format compatible with CSV for easy offline analysis; supports automatic data backup, with no data loss after power failure.

3. Environmental and Protection Performance

Operating Environment: Temperature range -30℃~60℃, relative humidity 5%~95% (non-condensing); can operate stably in outdoor substations, high-temperature workshops, and coastal high-salt-fog environments;

Protection Rating: IP65 (enclosure), dustproof and waterproof, can be directly installed near outdoor equipment without additional protective boxes;

Anti-interference Performance: Complies with IEC 61000-6-2 industrial anti-interference standards; ESD (Electrostatic Discharge) protection ±4kV (contact discharge)/±8kV (air discharge); EFT (Electrical Fast Transient) protection ±2kV (power port)/±1kV (signal port), adaptable to the strong electromagnetic environment of substations.

4. Diagnosis and Alarm Functions

Fault Diagnosis Algorithm: Built-in GE patented "Insulation Status Evaluation Model", which automatically determines fault types (partial discharge, low-temperature overheating, high-temperature overheating, arc discharge) based on the dissolved gas concentration ratio method (e.g., Duval Triangle, Rogers Ratio Method), with a diagnosis accuracy rate ≥90%;

Alarm Mechanism: Supports multi-level alarms (early warning, general alarm, emergency alarm), and alarm thresholds for each parameter can be customized (e.g., H₂ concentration ≥150μL/L triggers early warning); alarm methods include local sound and light alarm (LED indicator + buzzer), remote SMS/email alarm (requires 4G module support), and monitoring system pop-up alarm;

Trend Analysis: Automatically generates historical trend curves (daily/weekly/monthly/yearly) for each parameter; judges the fault development speed through the trend slope (e.g., H₂ concentration increasing by more than 50μL/L per week indicates accelerated fault), assisting operation and maintenance personnel in evaluating the remaining service life of the equipment.

III. Installation and Operation & Maintenance

Installation Specifications

(1) Installation Method (Portable External Connection Type)

Installation Location Selection: Select a location near the sampling valve of the transformer/reactor (distance ≤2 meters), avoid direct sunlight and rain exposure; installation height 1.2-1.5 meters for easy operation by maintenance personnel;

Oil Circuit Connection:

Close the equipment sampling valve, connect the sampling valve to the oil inlet of the HYDRAN H201Ci-1 using a dedicated high-pressure hose (pressure resistance ≥10MPa); the hose length ≤3 meters, avoid bending;

Open the sampling valve to slowly vent air; after ensuring no air bubbles in the oil circuit, open the device's oil inlet valve and confirm the oil circuit is unobstructed (the device's "oil flow" indicator is on);

Electrical Connection:

Connect the power cable (AC 220V or DC 24V), clearly distinguish between live wire, neutral wire, and ground wire; ground resistance ≤4Ω;

Communication cable connection: Use shielded twisted-pair cables (0.5mm²) for RS485 cables, with single-end grounding of the shield layer; use CAT5e shielded cables for Ethernet cables, connecting to the monitoring system switch;

Power-on Debugging: Turn on the power; the device automatically completes self-inspection (about 30 seconds); after passing self-inspection, it enters normal monitoring mode; check whether the display of each parameter is normal (e.g., the error between oil temperature and the equipment's built-in thermometer ≤1℃).

(2) Installation Precautions

Flush the hose with insulating oil before oil circuit connection to prevent impurities from entering the device;

Do not disassemble the oil circuit when the equipment is energized; if disassembly is required, first close the sampling valve and release pressure;

For outdoor installation, ensure the device's waterproof seal ring is intact to prevent rainwater from seeping into the internal circuit.

2. Daily Operation & Maintenance

(1) Regular Inspection (Once a Month)

Appearance Inspection: Check for shell damage, loose cable connections, and oil circuit leakage;

Local Data Verification: Check the device display to confirm that all parameters are within the normal range (e.g., H₂<100μL/L, moisture <30ppm) and there is no alarm information;

Oil Circuit Maintenance: Open the device's drain valve, discharge a small amount of insulating oil (about 50mL), check the oil sample for impurities, and ensure the oil circuit is unobstructed.

(2) Regular Calibration (Once a Year)

Gas Calibration: Use GE's dedicated standard gas (e.g., mixed gas of H₂ 100μL/L and CH₄ 50μL/L), inject it through the device's calibration interface, start the automatic calibration program, and save the calibration data after calibration;

Moisture Calibration: Use standard moisture oil samples (e.g., 10ppm, 100ppm), connect them to the device's moisture calibration interface; after calibration, verify the measurement error (required to be ≤±5%);

Calibration Records: Record the calibration date, calibrator, and errors before and after calibration; calibration data is automatically stored in the SD card for easy traceability.

(3) Troubleshooting