Connecting Pipeline With ASME Socket Welding SA182F317L Stainless Steel Flange and American Forged Cake

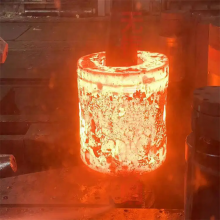

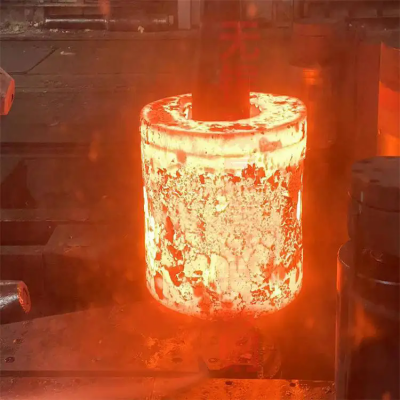

Product Overview

This product is a high - quality solution for connecting pipelines, which consists of an ASME socket welding SA182F317L stainless steel flange and an American forged cake. The combination of these two components provides a reliable and durable connection for various pipeline systems. This setup is suitable for a wide range of industries, including chemical processing, oil and gas, and food and beverage, where the integrity of pipeline connections is of utmost importance.

Manufacturing Details

- Manufacturing Way: Forging The flange and the forged cake are both manufactured through the forging process. Forging offers several advantages. It enhances the mechanical properties of the materials, such as strength and toughness. The grains in the metal are aligned during forging, which results in a more uniform and reliable structure. This makes the components less prone to cracking and failure under high - pressure and high - stress conditions.

- Material: Stainless Steel (SA182F317L) The use of SA182F317L stainless steel is a key feature of this product. Stainless steel is well - known for its excellent corrosion resistance. The “L” in SA182F317L indicates a low - carbon version, which further improves its resistance to intergranular corrosion, especially in welded areas. This makes it ideal for applications where the pipeline may come into contact with corrosive substances, such as acids, alkalis, and saltwater.

Structural Features

- Connection: Flanged The flanged connection provides a secure and leak - proof joint between the pipeline and other components. Flanges are designed to be easily bolted together, allowing for quick installation and maintenance. The ASME socket welding design ensures a tight fit, minimizing the risk of fluid leakage. This type of connection is also suitable for high - pressure applications, as the flanges can withstand significant forces without compromising the integrity of the joint.

- Structure: Round The round structure of the flange and the forged cake is not only aesthetically pleasing but also functionally efficient. A round shape distributes stress evenly around the circumference, which is beneficial for withstanding internal pressure in the pipeline. It also allows for a smooth flow of fluids through the pipeline, reducing turbulence and pressure drop.

Technical Specifications

- ASME Standards Compliance The SA182F317L stainless steel flange is manufactured in accordance with ASME standards. ASME (American Society of Mechanical Engineers) standards are widely recognized and respected in the industry for ensuring the quality and safety of mechanical components. By adhering to these standards, the product meets strict requirements for dimensions, material properties, and performance, providing customers with confidence in its reliability.

- Compatibility This product is designed to be compatible with a variety of pipeline sizes and materials. Whether you are using carbon steel, stainless steel, or other alloy pipes, the ASME socket welding SA182F317L stainless steel flange can be easily integrated into your existing pipeline system. The American forged cake is also engineered to work seamlessly with the flange, ensuring a proper fit and connection.

Company Background

Our company, established in 2017, is a professional manufacturer of stainless steel, alloy steel pipe, nickel - based alloy, and titanium alloy products. With an annual export share ranging from US$5 Million - US$10 Million and a team of 11 - 20 experienced salespersons, we have a strong presence in multiple markets around the world, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as the domestic market. Our commitment to quality and customer satisfaction has earned us a good reputation in the industry.

Applications

- Chemical Industry In the chemical industry, pipelines are often used to transport various corrosive chemicals. The corrosion - resistant SA182F317L stainless steel flange and the reliable forged cake connection ensure the safe and efficient transfer of these substances.

- Oil and Gas Industry In the oil and gas sector, high - pressure and high - temperature conditions are common. The forging - manufactured components can withstand these harsh environments, providing a long - lasting and reliable pipeline connection.

- Food and Beverage Industry The hygienic properties of stainless steel make this product suitable for the food and beverage industry. It can be used in pipelines for transporting food products, ensuring that there is no contamination and maintaining the quality of the products.

Send Inquiry to This Supplier

You May Also Like

-

Metallurgical Construction ASME Flanged Ring Plate SA182F316L Stainless Steel Flange American Standard ForgingNegotiableMOQ: 100 Pieces

-

ASME/AST American Standard A182F11 Flange F12 Customized P22 Eccentric ReducerNegotiableMOQ: 100 Pieces

-

Metallurgical Construction ASME Neck Flat Welding SA182F347H Stainless Steel Flange American Standard ForgingNegotiableMOQ: 100 Pieces

-

ASME Flat Welding Ring Loose Sleeve SA182F904L Stainless Steel Flange American Standard Forged for Power EngineeringNegotiableMOQ: 100 Pieces

-

Forged Forging A335P91 Flange DN200 PN16 Pressure Surface IntactNegotiableMOQ: 100 Pieces

-

ASME Neck Welding Ring Loose Set SA182F304 Stainless Steel Flange American Forged Ring for Power EngineeringNegotiableMOQ: 100 Pieces

-

The Surface of the A182F12 Flange F91 Diagonal Tee of the Takeover Seat Pipeline is IntactNegotiableMOQ: 100 Pieces

-

Complete Specifications A182F22 Flange 15NiCuMoNb5-6-4 Elbow Production FactoryNegotiableMOQ: 100 Pieces

-

12cr1mov Flange F11 Grade HG/T20592 for Petrochemical PipelinesNegotiableMOQ: 100 Pieces

-

1Cr5Mo Flange Corrosion-resistant High-temperature Production Plant for Petrochemical PipelinesNegotiableMOQ: 100 Pieces