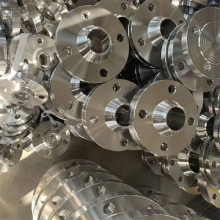

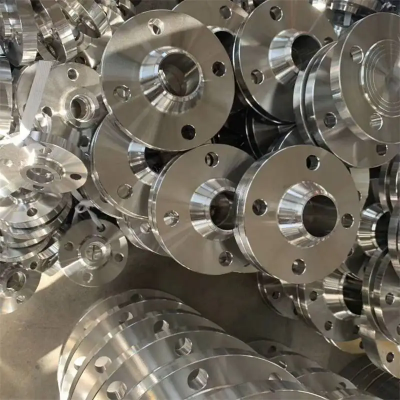

Connecting Pipeline With ASME Flanged Ring Plate SA182F317L Stainless Steel Flange and American Forged Ring

Our ASME flanged ring plate SA182F317L stainless steel flange, combined with an American forged ring, is a top - notch solution for connecting pipelines in various industrial applications. This product is meticulously crafted to meet the highest international standards, offering reliability and durability.

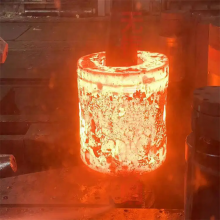

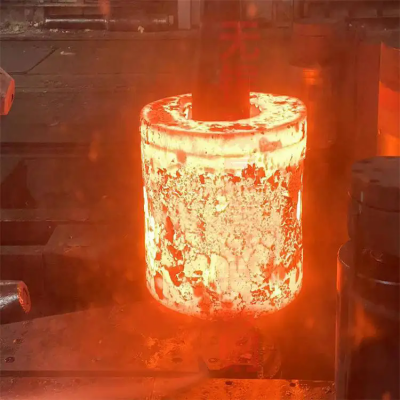

Manufacturing Way: Forging

Forging is a highly regarded manufacturing process that imparts superior strength and integrity to the flange. During forging, the metal is heated and shaped under high pressure, which aligns the grain structure of the stainless steel. This results in a flange that can withstand high - stress environments, such as those with significant pressure fluctuations or vibrations in pipeline systems.

Structure: Round

The round structure of the flange is designed for optimal flow distribution within the pipeline. It ensures a smooth and efficient transfer of fluids or gases, minimizing turbulence and pressure drops. This round design also allows for easy installation and compatibility with standard round pipes, facilitating seamless integration into existing or new pipeline networks.

Material: Stainless Steel SA182F317L

SA182F317L is a low - carbon version of the 317 stainless steel alloy. It contains a higher percentage of chromium, nickel, and molybdenum compared to other common stainless steels. The chromium forms a passive oxide layer on the surface of the flange, providing excellent resistance to oxidation and corrosion. The nickel enhances the alloy's toughness and ductility, while the molybdenum significantly improves its resistance to pitting and crevice corrosion. This makes the flange suitable for use in harsh environments, including those exposed to seawater, chemicals, and acidic substances.

Connection: Flanged

The flanged connection is a widely used method in pipeline systems due to its ease of installation, disassembly, and maintenance. The ASME flanged ring plate design ensures a secure and leak - tight connection. It allows for easy alignment of the pipes and can be tightened using bolts and gaskets. The flange's dimensions are in strict accordance with ASME standards, which means it can be easily paired with other ASME - compliant pipes and fittings from different manufacturers. The American forged ring further enhances the connection's strength and stability, providing a reliable joint for long - term use.

Industrial Applications

This product is suitable for a wide range of industries, including oil and gas, chemical processing, power generation, and water treatment. In the oil and gas industry, it can be used in offshore platforms, refineries, and pipelines for transporting crude oil, natural gas, and refined products. In chemical processing plants, it can handle various corrosive chemicals and solvents. In power generation, it is ideal for steam and water pipelines in thermal power plants and nuclear power facilities. In water treatment plants, it can withstand the corrosive effects of treated water and chemicals used in the purification process.

Our company, established in 2017, is a manufacturer with a strong focus on high - quality stainless steel products. We specialize in stainless steel, alloy steel pipes, nickel - based alloys, and titanium alloys. With an annual export share ranging from US$5 Million to US$10 Million, we have a well - established presence in multiple global markets, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid - East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as the domestic market. Our team of 11 - 20 experienced sales representatives is dedicated to providing excellent customer service and technical support to our international clients. Whether you are looking for a reliable solution for a new pipeline project or need to replace existing flanges, our ASME flanged ring plate SA182F317L stainless steel flange with an American forged ring is the ideal choice for your pipeline connection needs.

Send Inquiry to This Supplier

You May Also Like

-

Metallurgical Construction ASME Neck Flat Welding SA182F347H Stainless Steel Flange American Standard ForgingNegotiableMOQ: 100 Pieces

-

ASME Flat Welding Ring Loose Sleeve SA182F904L Stainless Steel Flange American Standard Forged for Power EngineeringNegotiableMOQ: 100 Pieces

-

Forged Forging A335P91 Flange DN200 PN16 Pressure Surface IntactNegotiableMOQ: 100 Pieces

-

ASME Neck Welding Ring Loose Set SA182F304 Stainless Steel Flange American Forged Ring for Power EngineeringNegotiableMOQ: 100 Pieces

-

The Surface of the A182F12 Flange F91 Diagonal Tee of the Takeover Seat Pipeline is IntactNegotiableMOQ: 100 Pieces

-

Complete Specifications A182F22 Flange 15NiCuMoNb5-6-4 Elbow Production FactoryNegotiableMOQ: 100 Pieces

-

12cr1mov Flange F11 Grade HG/T20592 for Petrochemical PipelinesNegotiableMOQ: 100 Pieces

-

1Cr5Mo Flange Corrosion-resistant High-temperature Production Plant for Petrochemical PipelinesNegotiableMOQ: 100 Pieces

-

ASME/ASTM American Standard A182F22 Flange 15NiCuMoNb5-6-4 ElbowNegotiableMOQ: 100 Pieces

-

Connecting Pipeline With ASME Neck Butt Welding Ring Loose Sleeve SA182F316 Stainless Steel Flange American Standard Forged PipeNegotiableMOQ: 100 Pieces