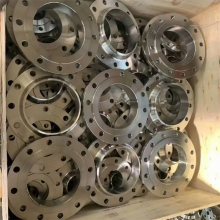

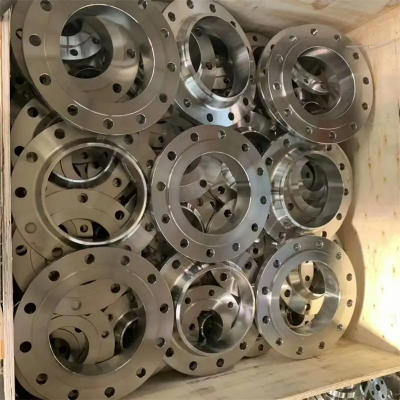

ASME Flat Welding Ring Loose Sleeve SA182F904L Stainless Steel Flange American Standard Forged for Power Engineering

The ASME flat welding ring loose sleeve SA182F904L stainless steel flange is a high - quality component specifically designed for power engineering applications. Manufactured through the forging process, this flange adheres to the American standard, ensuring its compatibility and reliability in a wide range of power systems around the world. The use of SA182F904L stainless steel material gives it excellent corrosion resistance and mechanical properties, making it suitable for both on - shore and off - shore power projects.

2. Material AdvantagesThe SA182F904L stainless steel is a key feature of this flange. It contains a high percentage of chromium, nickel, and molybdenum, which contribute to its outstanding corrosion resistance. This is particularly important in power engineering, where flanges are often exposed to harsh environments such as high - humidity areas, corrosive chemicals in cooling systems, or seawater in coastal power plants. Additionally, the low carbon content in SA182F904L reduces the risk of carbide precipitation during welding, ensuring the integrity of the flange's structure after installation.

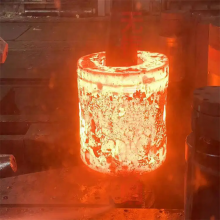

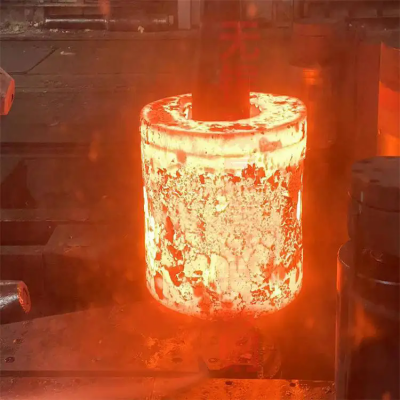

3. Forging ManufacturingForging is the manufacturing method employed for this flange. Forging offers several benefits over other manufacturing processes. Firstly, it refines the grain structure of the stainless steel, resulting in improved mechanical properties such as higher strength and better ductility. The forged flange can withstand higher pressure and stress compared to cast or machined flanges. Secondly, forging eliminates internal defects such as porosity and inclusions, enhancing the overall quality and reliability of the product. This makes the forged SA182F904L flange a long - lasting and dependable choice for power engineering applications.

The flat welding ring loose sleeve design of this flange provides flexibility during installation. The loose sleeve can rotate freely around the pipe, which simplifies the alignment process during connection. This is especially useful in complex power engineering systems where precise alignment is crucial. The round structure of the flange is a standard and widely - used design in the industry. It ensures uniform distribution of stress around the circumference, reducing the risk of stress concentration and potential failure points. The flange is also designed with accurate dimensions according to the American standard, guaranteeing seamless connection with other components in the power system.

This flange uses a flanged connection method, which is a common and reliable way to connect pipes and other equipment in power engineering. The flanged connection allows for easy installation and disassembly, facilitating maintenance and repair work. Moreover, the ASME standard compliance of this flange ensures its compatibility with other American - standard components in the power system. Whether it is connecting to pumps, valves, or other pipes, this flange can be seamlessly integrated into the existing power infrastructure, reducing the need for custom - made adapters and minimizing installation time and costs.

In power engineering, this SA182F904L stainless steel flange has a wide range of applications. In thermal power plants, it can be used in steam pipelines, water supply and drainage systems, and chemical dosing systems. In hydro - power plants, it is suitable for penstocks, turbine inlet and outlet pipes, and cooling water circuits. In nuclear power plants, the high - quality and corrosion - resistant properties of the flange make it a safe and reliable choice for various piping systems. Additionally, in renewable energy power generation such as wind and solar power, this flange can be used in the connection of auxiliary systems, such as heat transfer fluid pipes in solar thermal power plants.

7. Quality AssuranceThe production of this SA182F904L stainless steel flange is carried out under strict quality control measures. Each flange undergoes a series of inspections, including non - destructive testing such as ultrasonic testing and magnetic particle testing to detect any internal or surface defects. Chemical composition analysis is also performed to ensure that the stainless steel meets the specified standards. The flanges are also pressure - tested to verify their ability to withstand the designed pressure in real - world applications. This comprehensive quality control process guarantees that only high - quality flanges are delivered to customers, providing peace of mind for power engineering projects.

8. Global Market ReachOur company, with years of experience in the industry, has a wide - reaching global market. We export this ASME flat welding ring loose sleeve SA182F904L stainless steel flange to North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid - East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, and South Asia. Our products have been well - received in both domestic and international markets due to their high quality, competitive price, and excellent after - sales service. Whether you are a large - scale power project developer or a small - scale equipment manufacturer, this SA182F904L stainless steel flange can meet your power engineering needs.

Send Inquiry to This Supplier

You May Also Like

-

1Cr5Mo Flange Corrosion-resistant High-temperature Production Plant for Petrochemical PipelinesNegotiableMOQ: 100 Pieces

-

ASME/ASTM American Standard A182F22 Flange 15NiCuMoNb5-6-4 ElbowNegotiableMOQ: 100 Pieces

-

Connecting Pipeline With ASME Neck Butt Welding Ring Loose Sleeve SA182F316 Stainless Steel Flange American Standard Forged PipeNegotiableMOQ: 100 Pieces

-

Stainless Steel Flanges A182 F5 High Temperature Forged Forged Fittings Valve AccessoriesNegotiableMOQ: 1 Piece

-

Rolled Alloy Bars A182 F9 Precision Rolled Forged Parts High Temperature Stainless SteelNegotiableMOQ: 1 Piece

-

Forged Fittings A182 F11 Valve Parts S32100 High Temperature Forged Stainless ComponentsNegotiableMOQ: 1 Piece

-

Valve Accessories A182 F12 Stainless Steel Flanges Rolled Alloy Bars Forged FittingsNegotiableMOQ: 1 Piece

-

High Temperature Forged Bars A182 F22 Alloy Rolled Rods Stainless Steel Forged PartsNegotiableMOQ: 1 Piece

-

Stainless Steel Flanges A182 F91 Rolled Alloy Rods Forged Accessories High Temperature ForgedNegotiableMOQ: 1 Piece

-

Forged Fittings A182 F92 Valve Fittings High Temperature Rolled Alloy Bars Stainless SteelNegotiableMOQ: 1 Piece