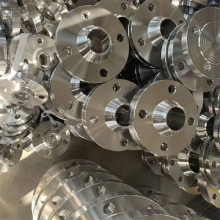

ASME/AST American Standard A182F11 Flange F12 Customized P22 Eccentric Reducer

Product Overview

Our ASME/AST American standard A182F11 flange, F12 customized, and P22 eccentric reducer are high - quality components designed to meet the diverse needs of various industrial applications. These products are crafted with precision and adhere to the strictest American standards, ensuring reliability and performance in demanding environments.

Manufacturing Details

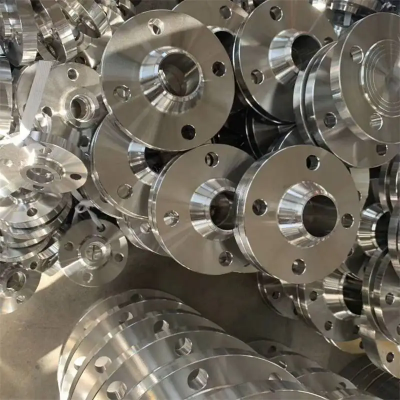

- Manufacturing Way: Forging The forging process is employed in the production of these components. Forging offers numerous advantages, such as enhanced mechanical properties. It aligns the grain structure of the metal, resulting in improved strength, toughness, and resistance to fatigue. This means that our flanges and reducers can withstand high - pressure and high - stress conditions without failure, making them suitable for long - term use in industrial pipelines and systems.

- Material: Stainless Steel We use high - grade stainless steel for these products. Stainless steel is known for its excellent corrosion resistance, which is crucial in applications where the components are exposed to harsh chemicals, moisture, or corrosive environments. It also has good heat resistance, allowing the flanges and reducers to maintain their structural integrity even at elevated temperatures. Additionally, stainless steel is hygienic and easy to clean, making it a popular choice in industries such as food processing and pharmaceuticals.

Structural Features

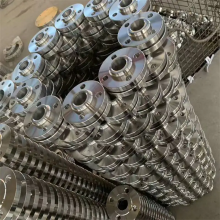

- Connection: Flanged The flanged connection design provides a secure and leak - proof joint. Flanges are easy to install and remove, facilitating maintenance and repair work on the pipeline system. They can be bolted together, and proper gasket materials can be used to ensure a tight seal. This type of connection also allows for easy disassembly and reassembly, which is beneficial in situations where system modifications or component replacements are required.

- Structure: Round The round structure of these components is not only aesthetically pleasing but also functionally advantageous. A round shape distributes stress evenly around the circumference, reducing the risk of stress concentration points. This results in a more stable and durable component. In addition, the round design is compatible with most standard pipeline systems, making it easier to integrate our flanges and reducers into existing infrastructure.

Customization Capabilities

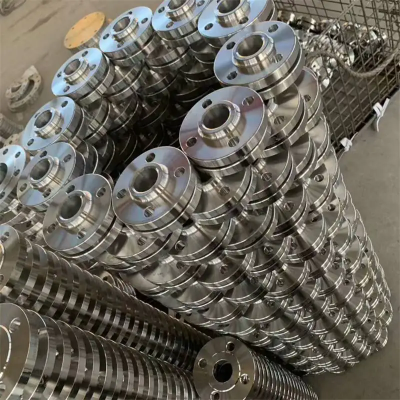

We offer customization services for the F12 component. This means that we can tailor the product according to your specific requirements, such as size, thickness, and special markings. Whether you need a non - standard size for a unique application or specific tolerances for a high - precision project, our experienced engineering team can work with you to create a customized solution. Our ability to customize ensures that you get exactly what you need for your industrial project.

Standards Compliance

These products strictly adhere to the ASME/AST American standards. Compliance with these standards guarantees that the components meet the highest quality and safety requirements. It also ensures compatibility with other equipment and components in the pipeline system that are also designed to these standards. This standardization simplifies the installation process and reduces the risk of compatibility issues, providing a seamless integration into your existing or new industrial setups.

Company Background

Our company, established in 2017, is a leading manufacturer in the field of stainless steel products. We specialize in stainless steel, alloy steel pipes, nickel - based alloys, and titanium alloys. With an export share ranging from US$5 Million - US$10 Million, we have a strong presence in multiple international markets, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as the domestic market. Our team of 11 - 20 professional sales representatives is dedicated to providing excellent customer service and technical support. Whether you are in the early stages of project planning or need immediate product delivery, we are here to assist you.

Applications

These ASME/AST American standard A182F11 flanges, F12 customized components, and P22 eccentric reducers are widely used in various industries. In the oil and gas industry, they are used in pipelines for transporting crude oil, natural gas, and refined products. In the chemical industry, they are suitable for handling corrosive chemicals and high - pressure fluids. They are also commonly used in power generation plants, water treatment facilities, and food and beverage processing plants. Their versatility and high - quality make them an ideal choice for a wide range of industrial applications.

Quality Assurance

We implement a strict quality control system throughout the manufacturing process. From the selection of raw materials to the final inspection of the finished products, every step is carefully monitored. Our quality control team uses advanced testing equipment and techniques to ensure that each component meets the required specifications. This includes non - destructive testing methods such as ultrasonic testing and magnetic particle testing, as well as destructive testing for mechanical properties. By maintaining high - quality standards, we ensure that our customers receive reliable and long - lasting products.

Send Inquiry to This Supplier

You May Also Like

-

Complete Specifications A182F22 Flange 15NiCuMoNb5-6-4 Elbow Production FactoryNegotiableMOQ: 100 Pieces

-

12cr1mov Flange F11 Grade HG/T20592 for Petrochemical PipelinesNegotiableMOQ: 100 Pieces

-

1Cr5Mo Flange Corrosion-resistant High-temperature Production Plant for Petrochemical PipelinesNegotiableMOQ: 100 Pieces

-

ASME/ASTM American Standard A182F22 Flange 15NiCuMoNb5-6-4 ElbowNegotiableMOQ: 100 Pieces

-

Connecting Pipeline With ASME Neck Butt Welding Ring Loose Sleeve SA182F316 Stainless Steel Flange American Standard Forged PipeNegotiableMOQ: 100 Pieces

-

Stainless Steel Flanges A182 F5 High Temperature Forged Forged Fittings Valve AccessoriesNegotiableMOQ: 1 Piece

-

Rolled Alloy Bars A182 F9 Precision Rolled Forged Parts High Temperature Stainless SteelNegotiableMOQ: 1 Piece

-

Forged Fittings A182 F11 Valve Parts S32100 High Temperature Forged Stainless ComponentsNegotiableMOQ: 1 Piece

-

Valve Accessories A182 F12 Stainless Steel Flanges Rolled Alloy Bars Forged FittingsNegotiableMOQ: 1 Piece

-

High Temperature Forged Bars A182 F22 Alloy Rolled Rods Stainless Steel Forged PartsNegotiableMOQ: 1 Piece