12cr1mov Flange F11 Grade HG/T20592 for Petrochemical Pipelines

12Cr1MoV Flange F11 Grade HG/T20592 for Petrochemical Pipelines Product Description

1. Overview

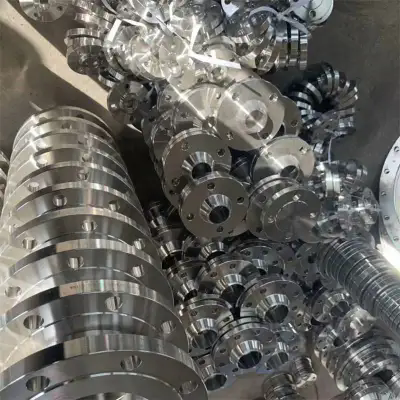

This 12Cr1MoV flange of F11 grade, conforming to the HG/T20592 standard, is a crucial component designed specifically for petrochemical pipelines. Petrochemical industry demands high - quality and reliable pipeline components due to the harsh working conditions, such as high pressure, high temperature, and the presence of corrosive substances. This flange is engineered to meet these stringent requirements, ensuring the safe and efficient operation of the entire pipeline system.

2. Manufacturing Details

- Manufacturing Way: The flange is manufactured through forging. Forging is a process that involves shaping metal by applying compressive forces. This method enhances the mechanical properties of the 12Cr1MoV material. It aligns the grain structure of the metal, making the flange more resistant to fatigue, impact, and deformation. Compared to cast flanges, forged flanges have better density and uniformity, which is essential for high - stress applications in petrochemical pipelines.

- Material Composition: The use of 12Cr1MoV steel is a well - thought - out choice. 12Cr1MoV is a low - alloy heat - resistant steel. The chromium (Cr) content provides excellent oxidation resistance, which is crucial as petrochemical pipelines often operate in environments with high - temperature oxygen - containing gases. The molybdenum (Mo) and vanadium (V) elements contribute to the high - temperature strength and creep resistance of the flange. This means that the flange can maintain its shape and mechanical properties even under long - term exposure to high temperatures and pressures, reducing the risk of failure.

3. Structural Features

- Structure: It has a round structure. The round shape is not only aesthetically pleasing but also functionally superior. A round flange provides a uniform distribution of stress around the circumference when connected to the pipeline. This uniform stress distribution helps to prevent stress concentration points, which could lead to cracks or leaks over time. Moreover, the round shape is easier to install and align with other pipeline components, facilitating a smooth and efficient installation process.

- Connection: The flange features a flanged connection. This type of connection is widely used in the petrochemical industry because it allows for easy assembly and disassembly of pipeline sections. Flanged connections also provide a reliable seal. Gaskets can be placed between the flanges to prevent the leakage of fluids or gases. The bolts and nuts used in the flanged connection can be tightened to a specific torque value, ensuring a secure and leak - free joint.

4. Standard Compliance

The flange adheres to the HG/T20592 standard. This standard is a well - established and recognized standard in the Chinese market for steel pipe flanges. It specifies the dimensions, technical requirements, inspection methods, and marking regulations for flanges. By complying with this standard, the 12Cr1MoV flange guarantees its compatibility with other pipeline components that also follow the same standard. This compatibility is essential for the seamless integration of the flange into existing or new petrochemical pipeline systems.

5. Performance in Petrochemical Applications

- High - Temperature Resistance: In petrochemical processes, pipelines often carry hot fluids or gases. The 12Cr1MoV flange can withstand high temperatures up to a certain range, depending on the specific operating conditions. This high - temperature resistance ensures that the flange does not lose its strength or integrity, preventing potential leaks or failures that could lead to safety hazards and production disruptions.

- Corrosion Resistance: Petrochemical substances can be highly corrosive. The alloying elements in 12Cr1MoV, especially chromium, form a passive oxide layer on the surface of the flange. This oxide layer acts as a barrier, protecting the underlying metal from corrosion. This corrosion resistance extends the service life of the flange, reducing the need for frequent replacements and maintenance, which in turn saves costs for petrochemical companies.

- Pressure Resistance: Petrochemical pipelines operate under high pressures. The forged structure and the high - strength 12Cr1MoV material enable the flange to withstand these high pressures without deforming or failing. This pressure - resistant property is vital for maintaining the integrity of the entire pipeline system and ensuring the safe transportation of petrochemical products.

6. Quality Assurance

The flange is produced by a professional manufacturer. The company has a strict quality control system in place. From the selection of raw materials to the final inspection of the finished product, every step is carefully monitored. The raw materials are sourced from reliable suppliers and are tested for their chemical composition and mechanical properties. During the manufacturing process, non - destructive testing methods such as ultrasonic testing and magnetic particle testing are used to detect any internal defects in the flange. Only products that pass all the quality tests are allowed to leave the factory, ensuring that customers receive high - quality and reliable flanges.

In conclusion, this 12Cr1MoV flange F11 grade HG/T20592 is an ideal choice for petrochemical pipelines. Its excellent manufacturing quality, structural features, and performance in harsh petrochemical environments make it a reliable and long - lasting component for any petrochemical pipeline project.

Send Inquiry to This Supplier

You May Also Like

-

Forged Fittings A182 F11 Valve Parts S32100 High Temperature Forged Stainless ComponentsNegotiableMOQ: 1 Piece

-

Valve Accessories A182 F12 Stainless Steel Flanges Rolled Alloy Bars Forged FittingsNegotiableMOQ: 1 Piece

-

High Temperature Forged Bars A182 F22 Alloy Rolled Rods Stainless Steel Forged PartsNegotiableMOQ: 1 Piece

-

Stainless Steel Flanges A182 F91 Rolled Alloy Rods Forged Accessories High Temperature ForgedNegotiableMOQ: 1 Piece

-

Forged Fittings A182 F92 Valve Fittings High Temperature Rolled Alloy Bars Stainless SteelNegotiableMOQ: 1 Piece

-

Rolled Alloy Bars A182 F36 Precision Rolled Forged Parts Stainless Steel High TemperatureNegotiableMOQ: 1 Piece

-

Valve Accessories A182 F6NM Forged Fittings Stainless Steel Flanges High Temperature ForgedNegotiableMOQ: 1 Piece

-

Stainless Steel Forged Parts A182 F304 High Temperature Rolled Alloy Bars Valve FittingsNegotiableMOQ: 1 Piece

-

Forged Fittings A182 F304H S30409 Stainless Steel Flanges High Temperature Rolled AlloyNegotiableMOQ: 1 Piece

-

Rolled Alloy Rods A182 F304L S30403 High Temperature Forged Stainless Steel Forged PartsNegotiableMOQ: 1 Piece