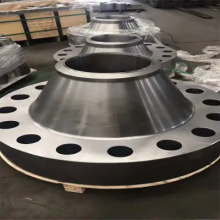

Forged Forging A335P91 Flange DN200 PN16 Pressure Surface Intact

The Forged A335P91 Flange DN200 PN16 is a crucial component in various industrial piping systems. Engineered with precision and manufactured using advanced forging techniques, this flange offers exceptional performance and reliability. It is designed to meet the demanding requirements of high - pressure and high - temperature applications, making it an ideal choice for industries such as power generation, oil and gas, and chemical processing.

Manufacturing ProcessForgingThis flange is crafted through the forging process. Forging involves shaping metal by applying compressive forces, typically using a hammer or a press. The forging process aligns the grain structure of the metal, which enhances the mechanical properties of the flange. This results in a product that has superior strength, toughness, and resistance to fatigue and impact compared to flanges made by other manufacturing methods. The forged A335P91 flange can withstand extreme operating conditions without compromising its integrity.

Technical SpecificationsDimensionsNominal Diameter (DN): DN200. This means that the flange is designed to be connected to pipes with an approximate inside diameter of 200 millimeters. The standard DN sizing ensures compatibility with a wide range of pipes in industrial settings.

Pressure Rating (PN): PN16. The PN rating indicates the maximum pressure that the flange can safely handle. A PN16 flange is suitable for applications with a maximum working pressure of 16 bar, providing a reliable connection in systems where pressure control is critical.

The pressure surface of the Forged A335P91 Flange DN200 PN16 is intact. This is of utmost importance as a smooth and intact pressure surface ensures a tight and leak - free connection. It allows for proper sealing when the flange is bolted to another flange or a pipe end, preventing any loss of fluid or gas in the piping system.

The flange is made of A335P91 stainless steel. This type of steel is known for its excellent high - temperature strength and corrosion resistance. It contains chromium, molybdenum, and vanadium, which contribute to its enhanced mechanical properties at elevated temperatures. A335P91 steel can maintain its strength and integrity even when exposed to temperatures up to 650°C, making it suitable for use in power plants, refineries, and other high - temperature industrial environments.

The flange features a flanged connection, which is a widely used method in piping systems. Flanged connections are easy to install and disassemble, allowing for convenient maintenance and repair of the piping system. They also provide a strong and reliable connection that can withstand high pressures and vibrations. The bolts used to connect the flanges are tightened to a specific torque, ensuring a secure and leak - proof joint.

In power plants, the Forged A335P91 Flange DN200 PN16 is used in steam piping systems. It can handle the high - pressure and high - temperature steam generated in boilers and turbines, ensuring efficient and safe operation of the power generation process.

Oil and Gas IndustryIn the oil and gas sector, this flange is employed in pipelines for transporting crude oil, natural gas, and refined products. Its corrosion resistance and high - pressure tolerance make it suitable for use in both onshore and offshore applications.

Chemical ProcessingChemical plants often require piping systems that can handle corrosive chemicals and high - pressure fluids. The A335P91 flange's corrosion - resistant properties and reliable connection make it a valuable component in chemical processing facilities, ensuring the safe transfer of various chemicals.

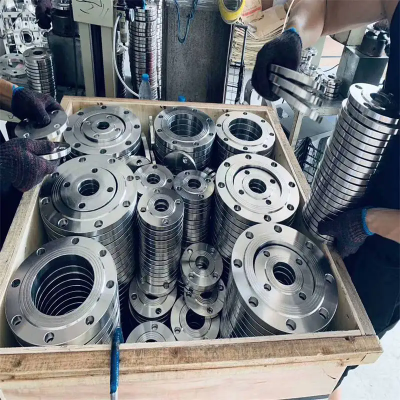

The Forged A335P91 Flange DN200 PN16 is manufactured in accordance with international quality standards. Rigorous quality control measures are implemented throughout the production process, from raw material inspection to final product testing. Each flange undergoes non - destructive testing methods such as ultrasonic testing and magnetic particle testing to detect any internal defects. This ensures that only high - quality flanges are delivered to customers, providing them with peace of mind and long - term reliability.

Packaging and ShippingThe flanges are carefully packaged to prevent any damage during transportation. They are usually wrapped in protective materials and placed in sturdy wooden crates. This packaging not only protects the flange from physical damage but also from environmental factors such as moisture and dust. We offer worldwide shipping services, ensuring that our products can reach customers in North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, and other regions in a timely and efficient manner.

Send Inquiry to This Supplier

You May Also Like

-

ASME/ASTM American Standard A182F22 Flange 15NiCuMoNb5-6-4 ElbowNegotiableMOQ: 100 Pieces

-

Connecting Pipeline With ASME Neck Butt Welding Ring Loose Sleeve SA182F316 Stainless Steel Flange American Standard Forged PipeNegotiableMOQ: 100 Pieces

-

Stainless Steel Flanges A182 F5 High Temperature Forged Forged Fittings Valve AccessoriesNegotiableMOQ: 1 Piece

-

Rolled Alloy Bars A182 F9 Precision Rolled Forged Parts High Temperature Stainless SteelNegotiableMOQ: 1 Piece

-

Forged Fittings A182 F11 Valve Parts S32100 High Temperature Forged Stainless ComponentsNegotiableMOQ: 1 Piece

-

Valve Accessories A182 F12 Stainless Steel Flanges Rolled Alloy Bars Forged FittingsNegotiableMOQ: 1 Piece

-

High Temperature Forged Bars A182 F22 Alloy Rolled Rods Stainless Steel Forged PartsNegotiableMOQ: 1 Piece

-

Stainless Steel Flanges A182 F91 Rolled Alloy Rods Forged Accessories High Temperature ForgedNegotiableMOQ: 1 Piece

-

Forged Fittings A182 F92 Valve Fittings High Temperature Rolled Alloy Bars Stainless SteelNegotiableMOQ: 1 Piece

-

Rolled Alloy Bars A182 F36 Precision Rolled Forged Parts Stainless Steel High TemperatureNegotiableMOQ: 1 Piece