Drawing and Sampling of 1Cr9Mo Flange for Takeover Seat Pipeline P11 Thick Wall

Product Overview

The 1Cr9Mo flange for takeover seat pipeline P11 thick wall is a crucial component in various industrial piping systems. This flange is meticulously designed and manufactured to meet the high - standard requirements of modern industrial applications, especially in environments where reliability and durability are of utmost importance.

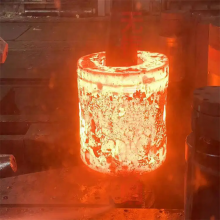

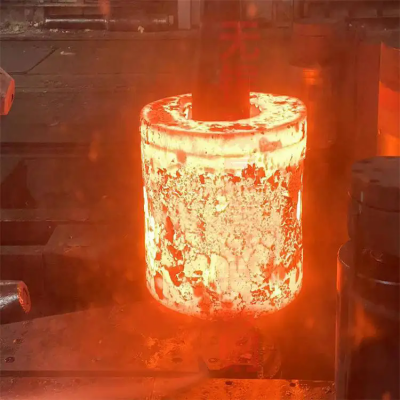

Manufacturing Way - Forging

The flange is produced through the forging process. Forging offers several significant advantages over other manufacturing methods. Firstly, it enhances the internal structure of the metal. During forging, the grains of the stainless - steel material are refined and oriented in a specific direction, which significantly improves the mechanical properties of the flange. This results in a flange that has high strength, good toughness, and excellent resistance to fatigue and impact. Secondly, forging can eliminate internal defects such as porosity and voids that might be present in cast parts. As a result, the 1Cr9Mo flange is more reliable and can withstand high - pressure and high - temperature conditions in the takeover seat pipeline P11 thick wall applications.

Connection - Flanged

The flanged connection design of this 1Cr9Mo flange provides a secure and leak - proof joint in the pipeline system. Flanged connections are easy to install and disassemble, which is very convenient for pipeline maintenance and repair. The flange has precise dimensions and flat surfaces, ensuring a tight fit when connected to other flanged components in the pipeline. This type of connection also allows for easy inspection and replacement of the flange if necessary. Additionally, the flanged connection can effectively distribute the stress across the joint, reducing the risk of failure due to stress concentration.

Structure - Round

The round structure of the 1Cr9Mo flange is a well - established and widely used design in the piping industry. The circular shape offers uniform stress distribution around the circumference of the flange, which is essential for maintaining the integrity of the pipeline under pressure. It also allows for seamless integration with other round - shaped components in the takeover seat pipeline P11 thick wall system. The round structure is easy to machine and manufacture, ensuring high precision and quality control during the production process. Moreover, it provides a smooth flow path for the fluid or gas passing through the pipeline, minimizing pressure drops and energy losses.

Material - Stainless Steel

The use of stainless steel as the material for this flange is a strategic choice. Stainless steel is known for its excellent corrosion resistance. In the takeover seat pipeline P11 thick wall applications, where the flange may be exposed to various corrosive substances such as chemicals, moisture, and oxygen, the stainless - steel material can effectively prevent rust and corrosion. This extends the service life of the flange and reduces the need for frequent replacements. Additionally, stainless steel has good heat resistance, which enables the flange to maintain its mechanical properties even at high temperatures. It also has high ductility, allowing the flange to deform slightly under stress without cracking, which is crucial for withstanding the dynamic forces in the pipeline system.

Application and Compatibility

The 1Cr9Mo flange for takeover seat pipeline P11 thick wall is highly versatile and can be used in a wide range of industries. It is commonly found in power generation plants, oil and gas refineries, chemical processing facilities, and other industrial settings where high - pressure and high - temperature pipelines are required. This flange is fully compatible with other components made of similar stainless - steel materials in the pipeline system. It can be easily paired with pipes, valves, and other fittings to create a complete and efficient piping network.

Quality Assurance

The 1Cr9Mo flanges are manufactured by Wuxi Weiman Gaodeng Special Steel Co., Ltd., a professional manufacturer established in 2017. With an export share ranging from US$5 Million - US$10 Million and a team of 11 - 20 experienced salespersons, the company has a proven track record in producing high - quality products. The company's products are exported to major markets around the world, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as the domestic market. The company adheres to strict quality control standards throughout the manufacturing process, from raw material inspection to the final product testing, ensuring that each 1Cr9Mo flange meets or exceeds international quality requirements.

Send Inquiry to This Supplier

You May Also Like

-

Metallurgical Construction ASME Flat Welding Ring Loose Sleeve SA182F310S Stainless Steel Flange American Standard Forged PipeNegotiableMOQ: 100 Pieces

-

Connecting Pipeline With ASME Flanged Ring Plate SA182F317L Stainless Steel Flange and American Forged RingNegotiableMOQ: 100 Pieces

-

Pressure Vessel ASME Neck Flat Welding SA182F304 Stainless Steel Flange American Standard ForgingNegotiableMOQ: 100 Pieces

-

Metallurgical Building ASME Large Diameter High Neck SA182F347H Stainless Steel Flange American Standard Shaped ForgingNegotiableMOQ: 100 Pieces

-

Pressure Vessel ASME Plate Flat Welding SA182F316 Stainless Steel Flange American Standard Forged CakeNegotiableMOQ: 100 Pieces

-

Metallurgical Construction ASME Flanged Ring Plate SA182F316L Stainless Steel Flange American Standard ForgingNegotiableMOQ: 100 Pieces

-

ASME/AST American Standard A182F11 Flange F12 Customized P22 Eccentric ReducerNegotiableMOQ: 100 Pieces

-

Metallurgical Construction ASME Neck Flat Welding SA182F347H Stainless Steel Flange American Standard ForgingNegotiableMOQ: 100 Pieces

-

ASME Flat Welding Ring Loose Sleeve SA182F904L Stainless Steel Flange American Standard Forged for Power EngineeringNegotiableMOQ: 100 Pieces

-

Forged Forging A335P91 Flange DN200 PN16 Pressure Surface IntactNegotiableMOQ: 100 Pieces