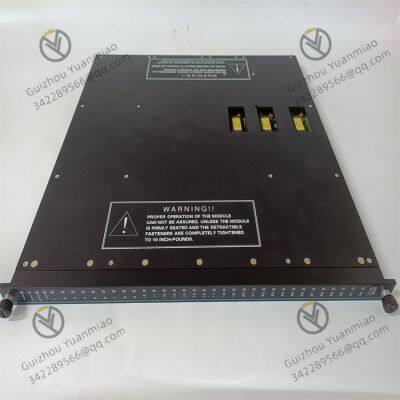

Triconex 3664 digital output module

Functional characteristics

Triple Redundancy Architecture: It adopts Triconex's signature Triple Module Redundancy (TMR) technology. There are three independent processor channels inside the module, and each channel can independently process input signals and output digital signals. Through a three-out of two voting mechanism, the accuracy and reliability of the output signal are ensured. Even if one channel malfunctions, it will not affect the normal operation of the module, effectively avoiding system downtime or misoperation caused by a single point of failure.

High reliability output: It has a powerful load driving capability and can directly drive industrial field equipment such as solenoid valves and contactors. The output state is stable and it can work reliably in harsh industrial environments (such as strong electromagnetic interference, high temperature, high humidity, etc.), ensuring the continuity of the industrial production process.

Fault diagnosis and fault tolerance: It has a complete self-diagnosis function and can monitor the working status of the module itself and the status of each output channel in real time. Once faults such as short circuit, open circuit or overcurrent in the channel are detected, an alarm will be triggered immediately. According to the preset fault safety policy, the output of the faulty channel can be forcibly set to a safe state (such as 0V or high resistance state) to prevent damage to the on-site equipment caused by the faulty output. At the same time, the fault information is promptly fed back to the control system through the communication interface. It is convenient for maintenance personnel to quickly locate and troubleshoot.

Flexible configuration: It supports flexible configuration of the output channels through programming software (such as TriStation 1131), including parameter Settings such as output modes (such as normally open and normally closed) and fail-safe modes, to meet the requirements of different industrial application scenarios.

Technical parameters

Number of channels: Usually 32 digital output channels, which can meet the requirements of large-scale digital output control.

Output type: Generally transistor output, it can provide dry contact or wet contact output methods. The common output voltage range is 24VDC, and some models also support higher voltage levels (such as 120/230VAC) to meet different load requirements.

Output current: The output current of a single channel is generally around 2A (the specific value varies by model), which can drive most loads such as solenoid valves and relays in industrial sites.

Isolation characteristics: There is excellent electrical isolation between channels and between channels and the system ground. The isolation voltage can usually reach over 2500VDC, effectively preventing signal interference and electrical safety hazards.

Operating temperature range: It can adapt to a relatively wide operating temperature range, generally from -40℃ to +75℃, and can operate stably in harsh industrial environments.

Communication interface: Supports multiple industrial communication protocols, such as Modbus, Profibus, Ethernet/IP, etc., facilitating data interaction and integration with other controllers and upper computer monitoring systems, and achieving remote monitoring and management.

Application scenarios

Petrochemical industry: In petroleum refining and chemical production facilities, it is used to control the emergency shutdown system (ESD). When abnormal situations occur, it can promptly cut off the power supply of key equipment or close valves to ensure production safety. It can also be used to control the start and stop of various valves and pumps in the process flow, ensuring that the production process proceeds according to the predetermined procedures.

Power industry: In power plants, it is used to control the start and stop of generator sets, the opening and closing operations of circuit breakers, as well as the state switching of various switchgear in the power system. In substations, the operation of relay protection devices is controlled to achieve the protection and control of power equipment.

Metallurgical industry: In the production processes of steel smelting, non-ferrous metal processing, etc., it controls the operating status of equipment such as blast furnaces, converters, and electric furnaces, such as controlling the start and stop of feeding equipment and the opening and closing of cooling system valves, etc. It can also be used for the action control of various mechanical devices in automated production lines, improving production efficiency and product quality.

The rail transit industry: In rail transit systems such as subways and high-speed railways, it is used to control the operation of equipment such as signal systems, door systems, and ventilation and air conditioning systems, ensuring the safe and punctual operation of trains.

Send Inquiry to This Supplier

You May Also Like

-

TRICONEX 3604E Digital Output ModuleNegotiableMOQ: 1 Piece

-

TRICONEX 3625C1 Digital Output ModuleNegotiableMOQ: 1 Piece

-

TRICONEX 3700A Analog Input ModuleNegotiableMOQ: 1 Piece

-

TRICONEX 3636R Relay Output ModuleNegotiableMOQ: 1 Piece

-

TRICONEX 3636T Digital Relay Output ModuleNegotiableMOQ: 1 Piece

-

TRICONEX 3700A Analog Input ModuleNegotiableMOQ: 1 Piece

-

TRICONEX 3704E Analog Input ModuleNegotiableMOQ: 1 Piece

-

TRICONEX 3805E High-speed Frequency/pulse Input ModuleNegotiableMOQ: 1 Piece

-

TRICONEX 3806E Analog Output ModuleNegotiableMOQ: 1 Piece

-

TRICONEX 4119A Mainframe Processor ModuleNegotiableMOQ: 1 Piece