China BEST Brand contour measurement machine

Contour Measurement Precision Instruments

Wilson, the ranking contour and roundness measuring machine manufacturer and supplier in China.

Wilson,one of the drafting members of the Industry Standard for Contour Measuring Machines(JB/T 11271-2012)

Wilson,one of the drafting members of the National Standard of Roundness Measuring Machines(GB/T 26098-2010)

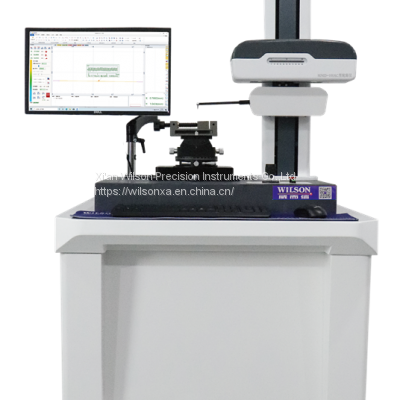

MMD-HPG series Contour & Roughness Measurement System (Mitutoyo analogue,Accretech variants), a high accuracy contact type CNC contour and surface roughness measuring system

To meet the request of contour and roughness combined measurements, the MMD-HPG series delivers a high level of metrological performance with resolution in nanometer range as well as residual error of <5nm Ra.

This MMD-HPG Series is an automated surface finish (roughness, waviness), form, contour measurement instrument designed for the shop floor environment. This equipment delivers 40-60 mm detector range and 0.001um resolution.

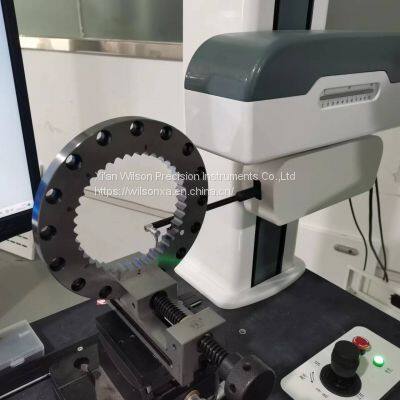

The system can be designed to your individual requirements for analysis of crankshafts, heads, blocks, gear box casings and so on.

Main parameters:

X axis(horizontal guide rail): 100-300 mm

Z1 axis(sensor): 40-60 mm

Z axis (column): 400-500 mm

Special models can be customized

Main Functions

1. Contour Measurement Function

Point: point, midpoint, intersection point, highest point, lowest point

Line: straight line, cut line, vertical line, parallel line, flat line

Circle: round, ellipse, cut circular

Angle: angle, horizontal angle, vertical angle

Position tolerance: straightness, convexity, contour, vertical, parallelism

Auxiliary generation: including auxiliary points, auxiliary lines, auxiliary circles

2. Roughness Analysis

Ra,Rq,Rz(Ry),Rz(DIN),R3z,Rz(jis),Rp,Rv,Rt,Rsk,Rsm,Rc,Rpm,Rku,Rdq,Roc,Mr1,Mr2,Rpk,Rvk,Rk,Rdc,A1,A2,R,Rx,AR,Rcp,Rmax,Rz-ISO

3. Waviness Analysis

wt,wa,wp,wv,wq,wc,wku,wsk,w,wx,wz,wsm,wdc,wte,wmr,Aw,c(wmr)wmr(c),wdq

Main features:

● The first domestic technology of autonomous intellectual property rights: using grating sensors to meet the measurement of roughness and contour size at the same time

● Use the interference to scan the grid ruler, which can reach 1nm, which can meet the super high precision measurement

● Ultra -high resolution sensor can meet the measurement of roughness and contour dimensions at the same time. No need to change the sensor during the measurement process

● A large number of processes and high precision are compatible, which can meet the integrated measurement of irregular surface roughness and size such as arc surface, column surface, free curved surface

● The unique roughness evaluation algorithm and position compensation method, effective correction and compensation surface measurement is the measurement error of non -plane, and effectively guarantee the roughness of the curved surface, the roughness of the arc workpiece as high accuracy and high accuracy as the plane roughness.

● No need to modify mathematical methods and close to zero friction coefficient rails, which can maintain a high -precision measurement benchmark for a long time. The accuracy is consistent.

● Custom template, batch measurement, automatic marking

Item/Model | MMD-HPG100 | MMD-HPG150 | MMD-HPG200 | MMD-HPG300 | |

Measuring range | X axis (horizontal guide) | 100mm | 150mm | 200mm | 300mm |

Z1 axis(sensor) | 40mm | 50mm | 60mm | 60mm | |

Z axis(column) | 450mm | 500mm | 500mm | 500mm | |

Machine weight | 300Kg | 350Kg | 400Kg | 450Kg | |

Overall size | Machine size | 915×720×1760mm | |||

Package size | 1000×900×2000mm | ||||

Send Inquiry to This Supplier

You May Also Like

-

High Level Analysis Multiple Function Surface Roughness Contour Measuring EquipmentNegotiableMOQ: 1 Set

-

High Level Surface Area AnalyzersNegotiableMOQ: 1 Set

-

Portable Surface Finish & Contour Measuring EquipmentUS$ 19999 - 29999MOQ: 1 Set

-

Auto Focus Surface Residual Thickness Measurement Gauge Vision Measuring MachineNegotiableMOQ: 1 Set

-

High Resolution VMM Auto Focus Indentation Measurement MachineNegotiableMOQ: 1 Set

-

Electronics Surface Profile Contour VMM Vision Measuring MachineNegotiableMOQ: 1 Set

-

China Contour Machine ManufacturerNegotiableMOQ: 1 Set

-

China CMM VMM Machine ManufacturerNegotiableMOQ: 1 Set

-

China Roughness Machine ManufacturerNegotiableMOQ: 1 Set

-

China Contour Machine ManufacturerNegotiableMOQ: 1 Set