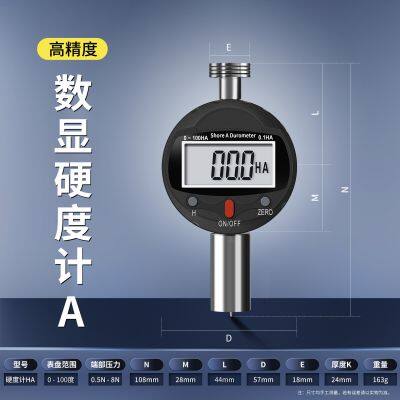

Instant Digital Readout: A high-contrast LCD screen displays hardness values in standard scales (e.g., Rockwell, Brinell, Vickers, Shore) with clear units, eliminating guesswork from analog dial interpretations.

Precision Engineering: Offers exceptional resolution (often 0.1 HR for Rockwell, 0.1 HB for Brinell) and repeatability, ensuring consistent results even for materials with varying textures, such as metals, plastics, rubber, or ceramics.

User-Friendly Design: Features one-touch operation, preset hardness scales, and automatic conversion between units, reducing training time and operational errors. Many models include a zero-set function for quick calibration.

Data Management: Equipped with USB or Bluetooth connectivity, it allows for seamless data storage, transfer to computers, or direct printing—critical for quality control documentation in manufacturing or laboratory settings.

Automotive & Aerospace: Testing the hardness of engine components, gears, or aircraft parts to ensure durability under extreme conditions.

Metallurgy: Evaluating metal alloys post-heat treatment to verify hardness consistency.

Plastics & Rubber Manufacturing: Assessing Shore hardness for products like gaskets, O-rings, or tires to meet elasticity standards.

Quality Assurance Labs: Conducting batch inspections to maintain compliance with industry specifications (e.g., ISO, ASTM).

Send Inquiry to This Supplier

You May Also Like

-

Large-range 0-200mm Digital Height GaugeNegotiableMOQ: 100 Cartons

-

Height GaugeNegotiableMOQ: 100 Cartons

-

Touch Screen Automatic Turret Digital Microhardness TesterUS$ 440 - 5000MOQ: 1 Piece

-

Rebound Tester for Concrete Hardness Rebound Value Measuring Device Concrete Compressive Strength TesterUS$ 750 - 900MOQ: 1 Set

-

High Precision Measuring Hardness MeterUS$ 80 - 100MOQ: 1 Unit

-

France Hardness Steel Plug Gauges for Measuring Gauging ToolsNegotiableMOQ: 1 Piece

-

Germany DIN VDE 0620-1-2010 Hardness Steel Plug Gauges for Measuring Gauging ToolsUS$ 200 - 650MOQ: 1 Piece

-

Hard Durable Solid Handheld Plastic Measuring Instrumen Made by Mould Injection Machine With IP67 Waterproof RC-PS 290/1US$ 4 - 300MOQ: 1 Piece

-

Digital Hardness TesterNegotiableMOQ: 50 Cartons

-

TIME®5303 for Mill Roll Hardness MeasurementUS$ Negotiable - NegotiableMOQ: 1 Set