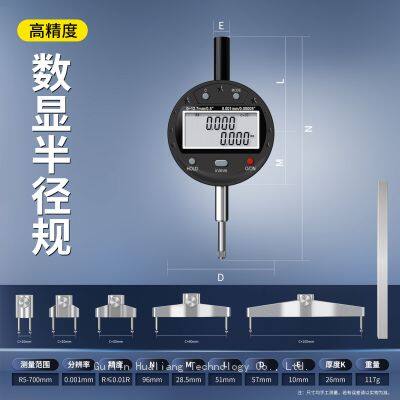

Introduction to Digital Radius Gauge

A digital radius gauge is a precision measuring instrument designed to accurately determine the radius of curved surfaces, arcs, or rounded edges. Equipped with a digital display and advanced sensing technology, it provides instant, high-precision readings, making it indispensable in industries such as manufacturing, machining, mold-making, automotive, and aerospace—where strict adherence to curved surface specifications is critical.

Key Features

Digital Display: Delivers clear, numerical readings in units like millimeters (mm) or inches (in), eliminating parallax errors common with analog radius gauges.

High Accuracy: Typically offers precision up to ±0.01 mm, ensuring reliable measurements for both small and large radii.

Versatile Probes: Features specially designed contact probes (often with rounded or curved tips) that conform to the target surface, enabling measurement of internal (concave) and external (convex) radii.

User-Friendly Functions: Includes one-button zero-setting (to calibrate at a reference point), unit conversion, data hold, and low-battery indicators for seamless operation.

Durable Construction: Built with robust materials (e.g., stainless steel probes, impact-resistant housing) to withstand industrial environments and repeated use.

Compact Design: Portable and lightweight, suitable for on-site inspections or workshop use.

Typical Applications

Measuring the radius of rounded edges on metal parts, plastic components, or glass panels.

Verifying the curvature of mold cavities, gears, or camshafts in manufacturing.

Inspecting aerospace or automotive parts (e.g., engine components, chassis edges) for compliance with design standards.

Quality control checks for curved surfaces in furniture, medical devices, or consumer products.

How It Works

The gauge’s probes are placed in contact with the curved surface, and internal sensors detect the distance between the contact points. Using built-in algorithms, the device calculates the radius based on the curvature and displays the result instantly on the digital screen. This method ensures quick, non-destructive measurement without damaging the workpiece.

Advantages Over Traditional Gauges

Faster measurement speed compared to manual analog gauges.

Reduced operator error with clear digital readings.

Ability to measure both internal and external radii with a single tool.

Enhanced precision for complex or small-radius surfaces that are hard to gauge manually.

In essence, the digital radius gauge streamlines quality control processes, ensuring curved surfaces meet design specifications with efficiency and accuracy—making it a vital tool for modern precision manufacturing.