Home > Products > die-cutting machine > high speed 300 cuts per minute paper label punching machine

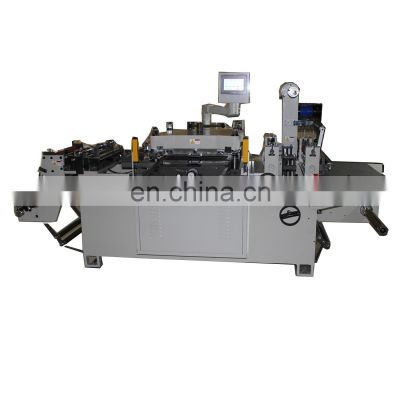

high speed 300 cuts per minute paper label punching machine

Negotiable

1 (Min.Order)

- 1000 per Month

- T/T Credit Card

You May Like

-

kapton tape sticker die cutting machine

-

Kiss Cut or Through Cut Die Cutting Machine 180cuts Per Minute Production Capacity

-

High Speed 300 Cuts Per Minute Paper Label Automatic Punching Die Cutting Machine Release Liner Rewind / Discharge Waste 320mm

-

DP-320B Self Adhesive Sticker Barcode Label Die Cutting Machine

-

Flat Bed Automatic Label Die Cutting Machine / Die Punching Machine

-

Adhesive Label, Foam Tape,sticker Paper Film Automatic Flat Bed Die Cutting Machine Label 180 Cuts/min Servo Motor Electric

Product Description

die cutting are | 500*500mm |

unwind width | 500mm |

cutting force | 10 Ton |

Torlence accuracy | ±0.1mm |

Power | 5KW |

material pulling | Servo driver |

WITH UP PUNCHING PLATE have clamping tool that install the cutting mould easily

special circuit and electric control system of high stability, up to Super level of effectiveness. Electronic positioning,

precision and control in 0.02mm, inferred from round precision control at 0. 05mm。 Machine feet install the SHIM, body solid and

reliable. Longer tool life, processing objects can be broken and half broken, cut smooth without edges. PLC man-machine automatic

program control oil system with integrated control, opto-electronic protection.

special circuit and electric control system of high stability, up to Super level of effectiveness. Electronic positioning,

precision and control in 0.02mm, inferred from round precision control at 0. 05mm。 Machine feet install the SHIM, body solid and

reliable. Longer tool life, processing objects can be broken and half broken, cut smooth without edges. PLC man-machine automatic

program control oil system with integrated control, opto-electronic protection.

Certifications

Thank you for your attention of our products , please feel free contact with us by below contact information

wechat Li13732669376

Product Description

First , Machine main technical data | ||

A. max die cutting speed 300 cuts/minute B. die cutting area 320*300mm(width * length ) C. unwind roll max diameter 500mm D. max paper roll diameter 320 mm E. left to right position precision : ±0.50mm F. Step Accuracy : ±0.10mm G. Total power : about 6.0kw H. Power Voltage: 1P 220V 50HZ I. Machine Net weight about 1650kg J. machine size(length *width * height ): 2700*1050*1400mm( Removable 1600*1050*1400mm) | ||

Second , machine configuration |

1 , unwinding part A. Aluminum guiding roller B. unwinding air-shaft C. unwind pulling material roller + steel roller D. unwind pulling material motor300W E. unwind damping device F. Electric Eye ( paperless automatic stop) 2, laminating part ( optional function ) 1. filming device ( unwinding function ) A. Filming unwinding roller 2. filming device ( unwind rewind function ) A. filming unwinding roller B. filming rewinding roller C. filming rewinding motor D. Aluminum guiding roller 3. Rectification system A.Aluminum guiding roller B. rectification motor 70W C. Rectification electric eye 4. printed mark tracing part A. Paper platform B. Electric eye holder C. Color tracking electric eye 5. punching hole part ( optional part ) 1.Mechanical type punching hole A. punching hole mold B. Connection block (connect with up die cutting plate) 2. Pneumatic punching hole A. punching hole mold B. Pneumatic cylinder 6. die cutting part A.Die cutting seat assembly (can move left and right – paper unwind direction) B. Main motor 2.2KW C.automatic supply oiling system ( copper tube connect wire, semi sealing type , Lubricating oil recycling ) D.Buffer spring E. Down cutting plate seat height adjustment ( 2 Inclined plate) F. Up cutting plate seat Obliquely turn up system ( more easy to change the cutting dies) 7. Pulling material part A.pulling material roller+ steel roller B.pulling material servo motor 2.2kw(Zhejiang Dongling) C.Timing belt 8. Waste scrap part A. guiding roller B. waste scrap rewind roller C. Buffer Disposal Device - Optional function (For some thick adhesive material difficult to scrap material ) 9. sheeting blade part A.Aluminum guiding roller B. Cutter clutch assembly C. up cutting blade (inserting steel) D. down cutting blade (inserting steel) 10. Rewinding part A. Aluminum guiding roller B. rewinding cushioning device C. Rewinding pulling material rubber roller+ steel roller D. rewinding motor 800W ( when sheeting can stop) 11. Hot foil stamping part ( optional part ) 1. Stepper motor stamping device A. Hot stamping unwind roller B. Aluminum guiding roller C. hot stamping pulling material roller D. hot stamping pulling material motor ( stepper motor ) 2. Servo motor hot stamping device A. Hot stamping unwind roller B. Aluminum guiding roller C. hot stamping pulling material roller D. hot stamping pulling material motor ( servo motor 0.75KW Zhejiang Dongling) 12. electric control part A.PLC (Panasonic) B.Touch screen ( Weinview TK6070IQ) C. Servo motor driver (Zhejiang Dongling) D. Frequency speed converter ( HUALAN) E. Power switch 220-2-110( Taiwan ) 13. metal sheet , safety cover etc 14. others A. Tools B. Operation manual |

MACHINE STRUCTURE

the machine has been extremely reliable , quiet and easy to use

Unwinding side

Below is our customer feedback

REWINDING SIDE

about the machine

Contact Us

- Kunshan Dapeng Precision Machinery Co., Ltd.

- Contact namePhoebe Chat Now

- Phone86-137-32669376

- AddressKunshan, No.511 North of Huangpujiang Road, Suzhou, Jiangsu

Product Categories

New Products

-

Automatic Roll to Roll Label/Tradmark Die Cutting Machine/Die Cutter

-

Graphene films punching machine

-

Screen Protector 3M tape adhesive label automatic die cutting machine

-

automatic foil die cutting hot stamping machine

-

die cutting and creasing machine

-

insulating material die cutting machine

-

automatic label die cutting machine

-

Automatic Flat Bed Die Cutter

-

DP-320B Automatic Label Die Cutting Machine 180 M/min Production Capacity 320*300mm about 8 Ton 320mm Max. Workable Width

-

Flexo Print Label a3 die cutting machine

-

mylar cutter with automatic die cutting

-

paper creasing machine and die cutting machine

-

High precision plastic die cutting machine

-

Flatbed Die cutting machine for paper label and films DP-320B

-

electronic sponges die cutting machine

-

Multifunctional roll paper automatic die-cutting machine

-

White Magnetic Labels die cutting machine ( die cutter)

-

iml label die cutting machine

-

Automatic Punching Machine Mechanical for Die Cutting Function 12 Months 320-450mm 650x600mm Motor,plc Provided 2515x1020x1810 ?

-

High Speed Sticker half cut printed label hot stamping Flatbed die Cutting Machine

-

High Accuracy Film Unwinding Copper Clad Rewinding Machine Aluminum Foil Unwinder

-

Rustproof Protected Unwinding Machine Unwinder Rewinder

-

PCB Production Paper Film Rewinding Machine Unwinder Rewinder

-

Production line Of INKJET PRINTING TATTOO UNWINDER REWINDER

Popular Searches

- shop press

- punch machine

- hydraulic press

- Artificial Press

- press machine

- forming press

- puncher

- Punching Machine

- Press Punching Machine

- Hydraulic Oil Press

- Hole Punching Machine

- Punching Press Machine

- Power Press Machine

- machine press

- Hole Punch

- punching tool

- punch press

- office punch

- punching equipment

- Can Punch

- Punching Machine Can Punch

- Rotary Tablet Press

- Hydraulic Press Tool

- Punch Tool

- power press

- Hydraulic Press Machine

- punching press

- Powder Press Machine

- Press Hydraulic Machine

- tablet press

Recommended Products

- MG266 Rolling machine for R side of electrical box

- MG260 Sink basin step rolling machine

- MG218 Vertical flattening machine

- MG213B Sink shaping machine

- MG263 Handmade sink corner press machine

- MG270 Hydraulic punch machine

- MG262 Plate splicing middle seam rolling machine

- MG216 3/4 big wheel for R corner and edges rolling machine with flange and step box

- MG215 3/4 big wheel R edges rolling machine with flange and step box

- MG213 R edges pressing machine

- Gold and silver coin commemorative medallion stamping hydraulic press

- Cuicl High precision CE ISO approved good quality 0.5T 1.0T 1.5T 2.0T small Electric Punching machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Machine Tools > Punching Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Kunshan Dapeng Precision Machinery Co., Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

Phoebe

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Phoebe

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile