Solid Carbide End Mill 6mm Handle 3D V-Groove Cutting Milling Cutter 60 90 120 150 Degree MDF Router Bit Customizable Wood ODM

As one of the mature CNC components manufacturers in China, HYCNC can provide various CNC router parts including spindle motors, CNC controllers, AC motor drivers, linear motion parts, servo motors and drivers. Our CNC Machines are extensively applicable in many areas of mechanical processing, such as the industrial, commercial and hobby sectors.

V Bit CNC

product name: | Woodworking V-shaped knife/ CNC router V bit |

product material: | Alloy tungsten steel material |

Product Specifications: | 6mm |

Applicable materials: | Solid wood board, hardwood, wood shavings |

Use purpose: | Board, density board, ecological board, etc. |

Use the machine: | Slotting, cutting, bottom cleaning, etc. |

Features Of Industrial Grade V Cutter

1. The blade body of this 60 degree CNC router bit for woodworking is made of hard tungsten steel, with high hardness and high wear resistance.

2. 45# steel knife handle, mirror grinding technology, smooth surface handle diameter, higher precision.

3. Coating frosting process technology, industry advanced coating to create a balanced paint surface, durable and temperature resistant.

4. The cutting edge is sharp, and high-precision processing can be performed. There is no smoke, no smoke and no burrs during processing.

HYCNC is specialized in manufacturing V Bit CNC/CNC vbit including V bit carving CNC, V groove bits for CNC, 60 degree V carve bits, V groove router bit for aluminum, CNC router V bits and V slot milling cutter, if you need them, contact us for more information.

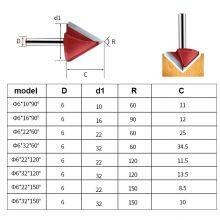

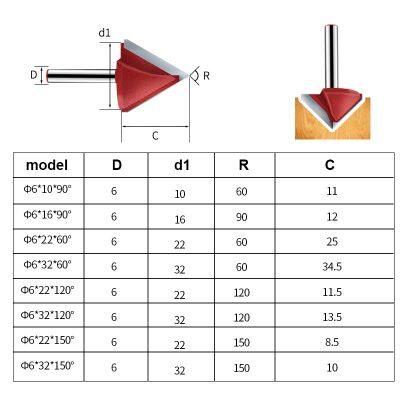

M0DEL | SHK | blade length | ANGLE | cutting deepth |

Φ6*10*60 | 6 | 10 | 60 | 11 |

Φ6*10 *90 | 6 | 10 | 90 | 11 |

Φ6*10*120 | 6 | 10 | 120 | 8.5 |

Φ6*16 *60 | 6 | 16 | 60 | 17 |

Φ6*16*90 | 6 | 16 | 90 | 12 |

Φ6*16*120 | 6 | 16 | 120 | 8 |

Φ6*22*60 | 6 | 22 | 60 | 25 |

Φ6*22*90 | 6 | 22 | 90 | 15 |

Φ6*22*120 | 6 | 22 | 120 | 11.5 |

Φ6*22*150 | 6 | 22 | 150 | 8.5 |

Φ6*32*60 | 6 | 32 | 60 | 34.5 |

Φ6*32*90 | 6 | 32 | 90 | 20.5 |

Φ6*32*120 | 6 | 32 | 120 | 13.5 |

Φ6*32*150 | 6 | 32 | 150 | 10 |

Brand: HYCNC

Name: 6MM V-shaped knife

Material: Tungsten steel blade/45# steel handle

Purpose: Slotting

Applicable materials: solid wood board, hardwood, particle board, density board, ecological board, plywood, etc.

Applicable equipment: electric wood milling, engraving machine, trimming machine (1/4 handle), hoisting machine, CNC, etc.

Recommended parameters: feed speed 8~12m/min,

Spindle speed: 18000~24000RPM

Send Inquiry to This Supplier

You May Also Like

-

800w Water Cooling Spindle Motor 220V 380V Woodworking Engraving Spindle ER11 Collet Φ62x160mm For CNC Milling Router MachineUS$ 81MOQ: 1 Carton

-

Engraving Machine Vacuum Pump Adsorption 5.5kw7.5kw Water Ring Circulating Air OpeningUS$ 372 - 568.6MOQ: 1 Carton

-

Super Wireless Lettering Treasure CNC Stone Engraving Leveling Stone Tablet Alphabet Leveling Instrument Path Measuring DeviceUS$ 261MOQ: 1 Combo

-

CNC Automatic Lubricating Oil Pump 2L With Pressure Gauge Digital Electronic Gear Pump 220V Oil Electromechanical Magnetic PumpUS$ 47.5 - 60MOQ: 1 Piece

-

NC Studio USB Wireless Remote Control Handle XHC WHB02 DSP Control Handle CNC Router Engraving And Cutting MachineUS$ 74.9MOQ: 1 Piece

-

1M X 70mm/100mm Dust Cover Brush Gold Brush Main Shaft Dust Brush Woodworking Dust Cover Brush CNC Router MotorUS$ 2.7MOQ: 1 Piece

-

Hiwin Linear Guide Slider Hgh15 20 25 30ca/Cc Slider Square Guide Rail Slide Linear Slide Table 3d Printing Cnc Diy PartsUS$ 21 - 200MOQ: 1 Box

-

Fuling 1.5KW Inverter 220v 380v Engraving Machine General High Speed Spindle MotorUS$ 140MOQ: 1 Piece

-

CNC Dust Collecting Cover Dust Cutting Woodworking Engraving Machine Dust Cover Two Or Three Or Four Processes Dust AccessoriesUS$ 41 - 92MOQ: 1 Combo

-

Precision 0.003 BT CNC Tool Holders ER11 ER16 ER20 ER25 ER32 ER40 Chucks for Turning Tool on Lathe Spindle Processing BT StandardUS$ 11 - 16MOQ: 1 Piece