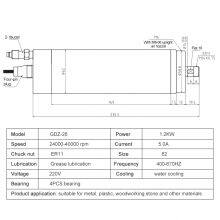

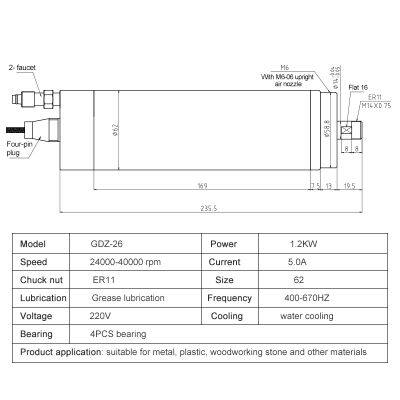

HQD 1.2KW ER11 62MM Water-cooled Spindle Motor 670Hz 40000rpm Woodworking Advertising Engraving Machine for CNC Router Milling

●The working environment temperature of the spindle is usually -10~40. ●Before installing the first electric spindle to rotate the spindle head by hand, you should feel flexibility and no blockage.

P4 fully sealed angular joint ceramic bearings can extend the life of the spindle. The longer the length, the greater the torque and the greater the power. Careful assembly makes the spindle more precise. Accuracy is 0.01mm, coaxial cable is less than 0.0025mm 1. Our ceramic ball bearing spindle uses 4 ceramic ball bearings. 2. Ceramic ball bearings are resistant to high temperature and low heat, and are usually 3-5 degrees lower than steel ball bearings during use. 3. Ceramic ball bearings have low friction, low noise and long service life. 4. If the spindle is used for aluminum or hardwood, ceramic ball bearings are better than steel ball bearings.

●When the spindle is stored and transported, the bearing condition inside the high-speed grease will change, and the customer should run it at low speed for 30 minutes. Then increase slowly at a speed of 3000 rpm, running for 20 minutes each time. The spindle and inverter should work together. The specifications and parameter settings of the inverter match the spindle parameters. ●To connect the inverter main shaft, the three-phase inverter power cord should be welded to the plug 1 (U), 2 (V), 3 (W) pin, and the grounded pin 4. After turning on the power, observe whether the spindle rotation axis always shows the direction. If it is inconsistent, turn it off immediately, and replace the two wires of the three-phase power supply connected to the inverter and the spindle. ●Before using the spindle every day, it must run at low speed for 15-20 minutes. Clamp the cutter on the spindle, the chuck nut, chuck, and cutter must be clean enough. The shank inserted into the chuck must be larger than 15mm.

●The water-cooled spindle must be used together with the water pump. Otherwise, the spindle will quickly break. ●The AC spindle motor must be used together with the inverter. The power of the inverter needs to be equal to or greater than the power of the spindle. Before use, please set the inverter parameters suitable for the spindle. Otherwise, the spindle and inverter will break immediately. ●When using the spindle, the noise is different from before, so please stop the spindle immediately. You need to replace the spindle bearing.

●The spindle frequency power supply is connected to the rated voltage, and the frequency should be consistent with the technical parameters of the electric spindle. The spindle speed can be adjusted to change the frequency, and the voltage changes in proportion. ●Do not use the spindle, the spindle should be oiled. Add anti-wave device and put it in a dry place. ●To replace the spindle bearing, some professional and technical personnel should be replaced. With special tools, the bearings should be cleaned thoroughly without removing the stator coil.

Send Inquiry to This Supplier

You May Also Like

-

Engraving Machine Vacuum Pump Adsorption 5.5kw7.5kw Water Ring Circulating Air OpeningUS$ 372 - 568.6MOQ: 1 Carton

-

Super Wireless Lettering Treasure CNC Stone Engraving Leveling Stone Tablet Alphabet Leveling Instrument Path Measuring DeviceUS$ 261MOQ: 1 Combo

-

CNC Automatic Lubricating Oil Pump 2L With Pressure Gauge Digital Electronic Gear Pump 220V Oil Electromechanical Magnetic PumpUS$ 47.5 - 60MOQ: 1 Piece

-

3.175 4 6mm Milling Cutter 3 Pyramid Carving Head 20-90 Degree Tip Tungsten Carbide End Mill For CNC Router Bit 3D MillingUS$ 4 - 7MOQ: 1 Piece

-

NC Studio USB Wireless Remote Control Handle XHC WHB02 DSP Control Handle CNC Router Engraving And Cutting MachineUS$ 74.9MOQ: 1 Piece

-

1M X 70mm/100mm Dust Cover Brush Gold Brush Main Shaft Dust Brush Woodworking Dust Cover Brush CNC Router MotorUS$ 2.7MOQ: 1 Piece

-

Fuling 1.5KW Inverter 220v 380v Engraving Machine General High Speed Spindle MotorUS$ 140MOQ: 1 Piece

-

CNC Dust Collecting Cover Dust Cutting Woodworking Engraving Machine Dust Cover Two Or Three Or Four Processes Dust AccessoriesUS$ 41 - 92MOQ: 1 Combo

-

Precision 0.003 BT CNC Tool Holders ER11 ER16 ER20 ER25 ER32 ER40 Chucks for Turning Tool on Lathe Spindle Processing BT StandardUS$ 11 - 16MOQ: 1 Piece

-

CNC Air-Cooled Spindle 800w 220V 380V Woodworking Spindle Motor Φ65x188 400Hz 24000RPM For CNC Router Milling Engraving MachineUS$ 61.3MOQ: 1 Carton