Large-Scale CNC Gear Hobbing Machine (six Axis With Four Linkage)

Large Scale CNC Gear Hobbing Machine

GH-800CNC6 GH-1250CNC6

Machine Summary

Based on the generating process, with carrying out index and differential compensation motions by electronic gear box(EGB), the model GH-800CNC6/GH-1250CNC6 heavy-duty gear hobbing machine is designed to cut cylindrical spur & helical gears, crowning or slightly tapered gears, worm wheels, splines, etc. This machine is used in the industries, such as mine machinery, marine, crane, metallurgy, lift, petroleum machinery, electricity generation equipment, engineering machinery.

Performance and Feature

1. The machine is of 6 axes with four axes coordinated control. CNC axes:

- A-axis--hob head swivel;

- B-axis--spindle ratation;

- C-axis--worktable rotation;

- X-axis--radial feed motion;

- Y-axis--tangential feed motion(hob shifting);

- Z-axis--axial feed motion;

- Four coordinated control axes: B,C,X and Z.

2. Carry out index and differential compensation motions by the electronic gearbox(EGB).

3. Fulfill heavy duty and powerful cutting by multi-start & high speed hob.

4. Productivity of the machine is 2 to 5 times higher than those general ones that of the same specifications.

5. Fault diagnostics function.

6. Auto. overload monitoring and alarm devices for spindle.

7. Quick retraction protection: in case of power off or failure occurred, synchronously and quickly ratract hob to avoid collision.

8. Parameter programming.

9. Symmetric construction of the machine bed ensure stable thermal balance.

10. Adopt large power AC spindle motor, power is transferred to cutter spindle by high precision helical gearing. Adopt a one-tooth difference clearance eliminating mechanism to improve transmission accuracy and rigidity. Equipped with auto hob arbor clamping device.

11. Large hydrostatic bearings and super precision Chinese patent double worm gearings system are for worktable, ensure the worktable has high static & dynamic rigidity and rotation accuracy, and driving with free-clearance.

12. Bulky parts are of high robust and rigidity, column and workstay are of double-wall, rib-reinforced and symmetric constructions, satisfy the needs of high speed and high efficient cutting.

13. Guideways for axes X,Y and Z are of ample hardened steel guideway, linear recirculating roller guidance systems are preloaded, ensure the guideways have high rigidity and accuracy. X, Y and Z axis are closed-loop controlled by linear enconder, ensure machining of stability dimension of the workpiece.

14. Adopt PROFI-BUS DT. Reasonable arrangement of pipelines and cables fully ensure the reliability of the control system.

15. Separated hydraulic, lubrication and cooling systems.

Technical Parameters

| Specifications | Units |

GH- 800CNC6 |

GH-1250CNC6 |

| Max. workpiece dia. | mm | 800 | 1250 |

| Max. module | mm | 16 | 16 |

| Max. axial travel | mm | 600 | 600 |

| NO. of teeth | 6-600 | 6-600 | |

| Max. hob dimension(diameter*length) | mm | Φ220*260 | Φ220*260 |

| Spindle taper bore | ISO50 | ISO50 | |

| Worktable surface diameter | mm | 750 | 930 |

| Max. hob head swivel angle | deg | ±45 | ±45 |

| Center distance between hob and worktable | mm | 75-560 | 100-780 |

| Distance between hob axis and worktable surface | mm | 200-800 | 450-1050 |

| Distance between workstay center end face and worktable surface | mm | 500-1100 | 750-1350 |

| Hob tangential travel | mm | 220 | 220 |

| Max. spindle speed | rpm | 275 | 275 |

| Max. worktable speed | rpm | 24 | 24 |

| Radial rapid travel | mm/min | 1500 | 1500 |

| Tangential rapid travel | mm/min | 1500 | 1500 |

| Axial rapid travel | mm | 1500 | 1500 |

| Main motor power | kw | 30 | 30 |

| Total power | Kva | 67 | 67 |

| Main machine weight | kg | 27000 | 30000 |

| No. of cases | 6 cases in total | 6 cases in total |

Standard Attachments

SIEMENS 840D CNC system

Φ40 hob arbor assembly

Fully enclosed guards

Hydraulic system

Cooling system

Circulating lubrication system

Automatic lubrication device

Oil mist collector

10.4" color display

Electrical cabinet with air conditioner

Hand hold unit

RS232 interface

Machine data storage disc

Indicating lamp for machine status

Dual-hand control function

Auto. hob arbor clamping device

Chip conveyor

Special tools for installation and adjustment

Isolating vibration pads

Manual flushing chip gun

Chip cart

Optional Attachments

FANUC 18i CNC system

Automatic loading & unloading system

Auto. workpiece storage

Workpiece fixture

Auto. door

Workpiece auxiliary support

Separated workpiece counter

Φ32 hob arbor assembly

Φ50 hob arbor assembly

Φ60 hob arbor assembly

Hob adjusting device

Deburring device

Workpiece positioning

Mechanism software for 4 axes coordinated control(B,C,X and Z-axis)

Man-machine conversation programming

Auto. tooth alignment function

Machining worm wheel in tangential method

Function of cutting cone root spline

Remote diagnostics function

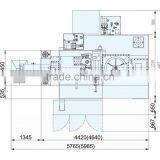

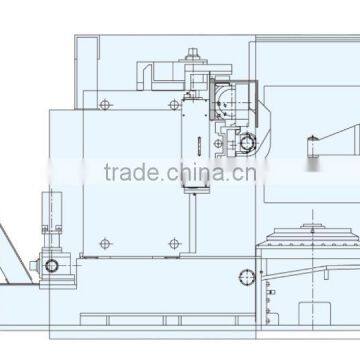

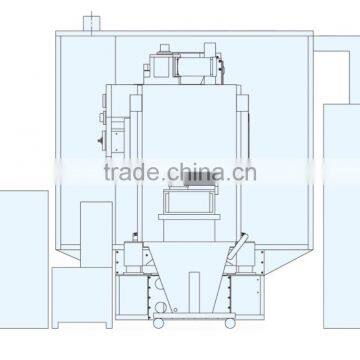

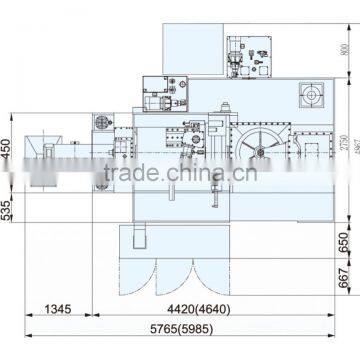

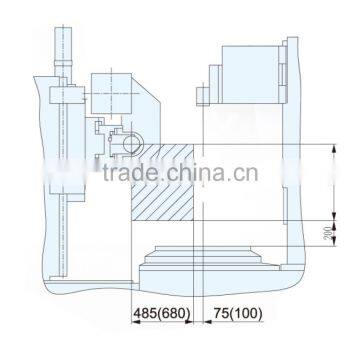

Components Plan

Send Inquiry to This Supplier

You May Also Like

-

Acrylic CNC Polishing Machines for Furniture IndustryNegotiableMOQ: 1 Set

-

Reliable Waterjet Cutting Machine for Stone Marble Porcleain Cutting IndustryUS$ 20000 - 40000MOQ: 1 Set

-

Custom Plastic Stainless Steel Aluminum CNC Machining PartNegotiableMOQ: 1

-

CNC Lathe Turned Machining Solid Shaft PinNegotiableMOQ: 1

-

Autopilot Flight Parts Manufacture and MIM Powder MetallurgyNegotiableMOQ: 1 Piece

-

Refrigerant gas R407NegotiableMOQ: 1 Piece

-

High Precision Machining Products of Stainless Steel Made in ChinaUS$ 1.5 - 1.5MOQ: 1000 Kilograms

-

Stainless Steel Welding Tee Pipe FittingsUS$ 0.9 - 0.9MOQ: 200 Pieces

-

OEM CNC Custom Machining Engineering Small Packaging Machine PartsUS$ 0.2 - 100MOQ: 1 Piece

-

Www.xtlaser.comHot Sale Dot Peen Pneumatic Marking MachineUS$ 1,400 - 1,600MOQ: 1 Set