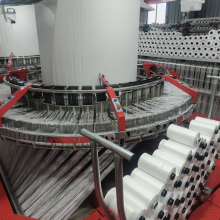

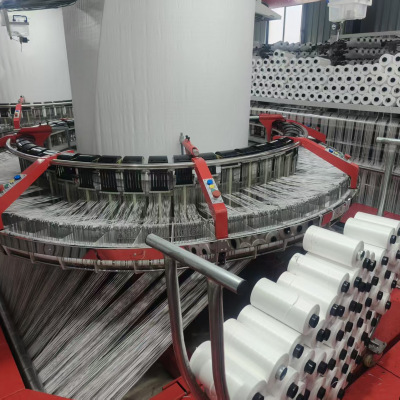

Heavy-Duty FIBC Circular Loom With 4 Shuttle System for Industrial Bag Production

Welcome from Xuzhou Guozi Intelligent Technology Co., Ltd., a trusted manufacturer based in the industrial hub of Xuzhou, Jiangsu, China. Our Heavy-Duty FIBC Circular Loom with 4 Shuttle System is engineered to revolutionize your industrial bag production, delivering unmatched efficiency and reliability for high-volume operations. Designed with precision, this loom ensures consistent output of durable FIBC bags, reducing downtime and maximizing your investment. With our expertise in intelligent weaving technology, we provide a solution that adapts to demanding industrial environments, helping you achieve superior productivity and cost savings. Experience the difference with a machine built to handle the toughest bag manufacturing challenges.

Key Features and Technical Specifications: This advanced loom incorporates a robust 4-shuttle system that significantly enhances weaving speed and versatility, allowing for seamless production of various bag sizes and materials. The heavy-duty construction features a high-strength steel frame, ensuring long-term durability even under continuous operation. Key benefits include:

- Enhanced Efficiency: The 4-shuttle design enables simultaneous weaving, cutting production time by up to 30% compared to single-shuttle systems, ideal for high-output facilities.

- Durability and Reliability: Built with corrosion-resistant materials, it withstands harsh industrial conditions, minimizing maintenance needs and extending machine lifespan.

- User-Friendly Operation: Equipped with intuitive controls and automated features, it reduces operator fatigue and training requirements, ensuring smooth workflow integration.

- Cost Savings: Optimizes material usage and energy consumption, lowering operational costs while boosting bag quality for better market competitiveness.

For detailed technical parameters, refer to the table below:

| Specification | Value |

|---|---|

| Weaving Width | Adjustable, 1.5m to 2.5m |

| Weaving Speed | Up to 100 rpm |

| Power Requirements | 380V, 50Hz, 3-phase |

| Material Compatibility | Polypropylene, woven fabrics |

| Shuttle Type | 4 independent shuttles |

This loom excels in producing FIBC bags for industries like agriculture, chemicals, and construction, with customizable options to meet specific production needs. Its precision engineering ensures uniform bag strength and weave density, critical for bulk material handling. Clients report reduced waste and faster ROI, thanks to its adaptable design that scales with growing demands.

Trust and Support: As a leading innovator from Xuzhou, Jiangsu, Xuzhou Guozi Intelligent Technology Co., Ltd. leverages decades of manufacturing excellence to deliver reliable, high-performance machinery. Our commitment to quality and customer support includes comprehensive after-sales services, ensuring your loom operates at peak efficiency. Partner with us for tailored solutions that drive your business forward—contact us today for a consultation or custom quote to elevate your bag production capabilities.

Frequently Asked Questions (FAQ):

-

Q: What is the typical production output of this loom?

A: Depending on settings, it can produce 400-600 FIBC bags per day, making it suitable for medium to large-scale operations. -

Q: Can the loom handle different bag sizes?

A: Yes, the adjustable width range allows customization for various bag dimensions, from small sacks to large bulk containers. -

Q: Is operator training included?

A: We provide optional on-site training and manuals to ensure smooth operation and maintenance. -

Q: What maintenance is required?

A: Regular lubrication and part inspections are recommended; spare parts are readily available upon request. -

Q: How long is the delivery time?

A: Standard delivery is 30-45 days after order confirmation, with expedited options customizable. -

Q: Are there warranty options?

A: A standard warranty covers parts and labor; extended plans are available upon request. -

Q: Can it integrate with existing production lines?

A: Absolutely, the design allows easy integration with automation systems for seamless workflow. -

Q: What power sources are supported?

A: It runs on 380V, 50Hz power, common in industrial settings; adapters may be customizable.

Send Inquiry to This Supplier

You May Also Like

-

Advanced Circular Loom for Jumbo Bag Making With Electronic Control PanelNegotiableMOQ: 1 Set

-

Industrial Circular Weaving Loom for Bulk FIBC Fabric, 4-8 Shuttles ConfigurationNegotiableMOQ: 1 Set

-

Precision Circular Loom for FIBC Material With Automatic Brake SystemNegotiableMOQ: 1 Set

-

High-Performance Circular Weaving Machine for Bulk Bag Fabric, 4-8 ShuttlesNegotiableMOQ: 1 Set

-

Heavy-Duty Circular Loom Machine for Jumbo Bag Production, 170-220cm WidthNegotiableMOQ: 1 Set

-

Robust FIBC Circular Loom Supporting Various PP Woven Bag SpecificationsNegotiableMOQ: 1 Set

-

High-Speed FIBC Circular Loom for PP Woven Bags With Automatic Control SystemNegotiableMOQ: 1 Set

-

Energy Saving Circular Loom Machine for FIBC and Big Bag ManufacturingNegotiableMOQ: 1 Set

-

Precision Circular Loom Machine for High-Quality FIBC Woven FabricNegotiableMOQ: 1 Set

-

Automatic Circular Loom Machine for Woven Sacks and FIBC Jumbo Bags ManufacturingNegotiableMOQ: 1 Set