FIBC Circular Loom for PP Woven Bag Production With 8 Shuttle Configuration

As a dedicated manufacturer from Xuzhou, Jiangsu, China, Xuzhou Guozi Intelligent Technology Co., Ltd. brings you our premium FIBC Circular Loom designed for high-efficiency PP woven bag production. This innovative loom features an 8 shuttle configuration, delivering superior weaving performance that enhances productivity and reliability in bulk bag manufacturing. Based in the industrial hub of Xuzhou, we leverage local expertise to create machinery that meets rigorous demands, helping businesses optimize their operations and reduce production costs. Our commitment to quality ensures that this loom provides a robust solution for scaling your woven bag output with minimal downtime.

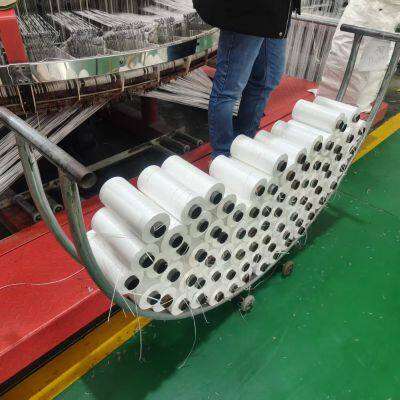

The FIBC Circular Loom excels in transforming polypropylene materials into durable woven bags for flexible intermediate bulk containers (FIBC). Key features include:

- Enhanced Speed and Efficiency: The 8 shuttle configuration allows for faster weaving cycles, significantly increasing output rates compared to standard models, which is ideal for high-volume production environments.

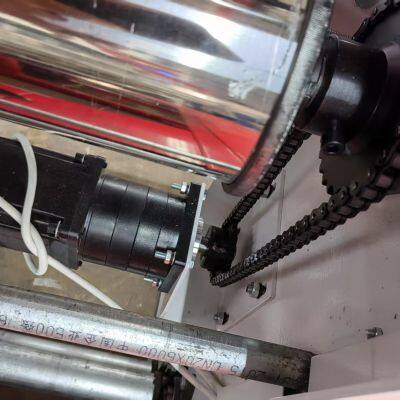

- Durable Construction: Built with a sturdy steel frame, this loom resists wear and tear in demanding industrial settings, ensuring longevity and consistent performance over time.

- User-Friendly Operation: Equipped with intuitive controls and automated adjustments, it simplifies setup and monitoring, reducing operator training time and minimizing human error.

- Versatile Application: Capable of producing various PP woven bag sizes for FIBC use, such as bags for agricultural, chemical, or construction materials, with customizable settings to match specific customer needs.

Technical specifications highlight the precision engineering of this loom. Below is a summary of key parameters:

| Parameter | Specification |

|---|---|

| Loom Diameter | Customizable (e.g., 1000mm to 2000mm) |

| Weaving Speed | Adjustable up to 150 rpm |

| Power Supply | 380V, 50Hz standard; other voltages available upon request |

| Material Compatibility | PP (polypropylene) yarns for woven bags |

| Control System | Digital interface for easy parameter adjustments |

Advantages for your business are substantial. This loom reduces fabric waste through precise tension control, leading to cost savings of up to 15% on raw materials. Its energy-efficient design lowers power consumption, while the high-speed operation cuts production time, enabling faster order fulfillment. Clients in industries like agriculture and logistics report improved bag strength and uniformity, enhancing end-product quality and customer satisfaction. Additionally, the low maintenance requirements translate to fewer disruptions and higher overall equipment effectiveness.

Hailing from Xuzhou, Jiangsu, a region known for advanced manufacturing, Xuzhou Guozi Intelligent Technology Co., Ltd. stands by the reliability and innovation of our FIBC Circular Loom. Our local presence ensures timely support, including installation assistance and troubleshooting, backed by years of industry experience. Choose this loom to elevate your PP woven bag production with a machine that combines cutting-edge technology and dependable performance. Explore how it can transform your operations—contact us today for a detailed consultation or to request a personalized quote.

Frequently Asked Questions (FAQ)

Q: What is the primary use of this FIBC Circular Loom?

A: It is designed for producing polypropylene woven bags used in flexible intermediate bulk containers (FIBC), such as for storing grains, chemicals, or minerals. The loom weaves fabric efficiently for bulk bag applications.

Q: How does the 8 shuttle configuration improve production?

A: The 8 shuttles allow simultaneous weaving actions, increasing speed and output compared to fewer-shuttle models. This reduces cycle times by up to 30% and boosts overall efficiency in high-demand settings.

Q: Can the loom handle different bag sizes or materials?

A: Yes, it is highly adaptable. With customizable diameter settings, it can weave bags of various sizes. While optimized for PP, it can work with similar synthetic yarns upon customer request.

Q: What training or support is provided with purchase?

A: We offer comprehensive on-site or virtual training for operators, along with detailed manuals. Ongoing technical support is available to address any operational queries and ensure smooth integration.

Q: Is the loom energy-efficient, and what are the power requirements?

A: Absolutely, it features an energy-saving design that minimizes power consumption. Standard power is 380V, 50Hz, but this can be adjusted to match local grid specifications if needed.

Q: What maintenance is required, and how often?

A: Routine maintenance includes lubrication and inspection every 500 operating hours. The machine is built for low upkeep, with accessible parts to simplify servicing and extend lifespan.

Q: How long does delivery take, and can it be customized?

A: Delivery typically ranges from 4-8 weeks after order confirmation, depending on customization. Yes, options like size adjustments or specific features can be tailored to your requirements.

Q: Does it come with a warranty, and what is covered?

A: A standard warranty covers parts and workmanship for one year. Extended coverage may be available upon request, ensuring peace of mind for your investment.

Send Inquiry to This Supplier

You May Also Like

-

High-Performance Circular Weaving Machine for Bulk Bag Fabric, 4-8 ShuttlesNegotiableMOQ: 1 Set

-

Heavy-Duty Circular Loom Machine for Jumbo Bag Production, 170-220cm WidthNegotiableMOQ: 1 Set

-

Robust FIBC Circular Loom Supporting Various PP Woven Bag SpecificationsNegotiableMOQ: 1 Set

-

High-Speed FIBC Circular Loom for PP Woven Bags With Automatic Control SystemNegotiableMOQ: 1 Set

-

Energy Saving Circular Loom Machine for FIBC and Big Bag ManufacturingNegotiableMOQ: 1 Set

-

Precision Circular Loom Machine for High-Quality FIBC Woven FabricNegotiableMOQ: 1 Set

-

Automatic Circular Loom Machine for Woven Sacks and FIBC Jumbo Bags ManufacturingNegotiableMOQ: 1 Set

-

Advanced Circular Loom Weaving Machine for Jumbo Bulk Bag ProductionNegotiableMOQ: 1 Set

-

High-Speed FIBC Circular Loom Machine for Jumbo Bag Production With 4 Shuttles SystemNegotiableMOQ: 1 Set

-

High-Performance FIBC Circular Loom for PP Woven Bag Production With Advanced Weaving TechnologyNegotiableMOQ: 1 Set