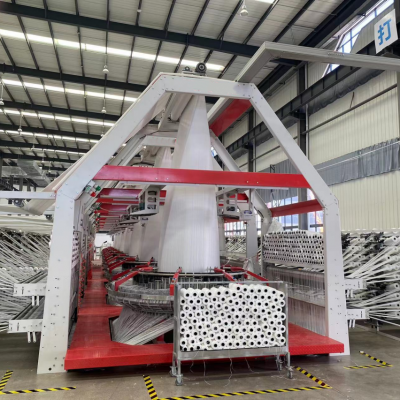

Automatic Circular Loom Machine for Woven Sacks and FIBC Jumbo Bags Manufacturing

As a leading manufacturer based in Xuzhou, Jiangsu, Xuzhou Guozi Intelligent Technology Co., Ltd. proudly presents our Automatic Circular Loom Machine – engineered to revolutionize woven sack and FIBC jumbo bag production. This industrial-grade equipment combines precision engineering with operational efficiency to deliver consistent fabric quality while reducing manufacturing costs. Our solution addresses critical production challenges through intelligent automation and robust construction.

The machine's core innovation lies in its synchronized operation system that maintains optimal tension control throughout the weaving process. This ensures uniform fabric density and minimizes material waste – crucial factors for bulk packaging manufacturers. With over a decade of specialized R&D in textile machinery, we've incorporated field-tested reliability into every component, from the heavy-duty frame to the advanced electronic controls.

| Feature | Specification |

| Weaving Mechanism | 4-8 shuttles (configurable) |

| Fabric Width Range | 750-2500 mm |

| Main Motor Power | 7.5-11 kW (model dependent) |

| Warp Beam Capacity | Φ800 mm standard |

| Tension Control | Electromagnetic brake system |

Operational advantages include:

- Energy-efficient design reduces power consumption by up to 25% compared to conventional models

- Quick-change components enable rapid fabric width adjustments within 15 minutes

- Self-diagnostic control panel displays real-time operational data and error codes

- Modular construction simplifies maintenance and part replacement

Manufacturers will appreciate the reduced downtime achieved through:

- Automatic shuttle changing without stopping production

- Precision gear transmission requiring lubrication only every 500 hours

- Vibration-dampening mounts that extend bearing life

Backed by our manufacturing expertise in China's industrial heartland, we provide comprehensive technical support including installation supervision and operator training. Our production facility in Xuzhou utilizes ISO-compliant quality control procedures, though specific certifications may vary by model. With customizable configurations available for specialized applications, this circular loom represents a long-term investment in production scalability.

-

Q: What maintenance frequency does this machine require?

A: Daily cleaning and weekly inspection of critical components are recommended, with major service intervals at 6 months depending on usage intensity. -

Q: Can it process recycled polypropylene materials?

A: Yes, the machine features enhanced extrusion components specifically designed to handle recycled PP flakes with consistent results. -

Q: What safety features are included?

A: Standard configurations include emergency stop buttons, overload protection, and interlocked safety guards on moving parts. -

Q: How quickly can fabric specifications be changed?

A: Width adjustment takes approximately 15 minutes with our quick-release mechanism, while weave density changes are programmable via the control panel. -

Q: Is technical training provided?

A: We offer comprehensive on-site training for operators and maintenance technicians during installation, plus remote support thereafter. -

Q: What's the typical lead time for delivery?

A: Standard models ship within 30 days after order confirmation, subject to production schedule and destination.

Engineered for continuous operation in demanding industrial environments, our circular loom delivers measurable ROI through superior fabric quality and reduced operational costs. Contact our Jiangsu-based engineering team today to discuss your specific production requirements and discover how our intelligent weaving technology can enhance your manufacturing capabilities.

Send Inquiry to This Supplier

You May Also Like

-

Versatile Circular Loom for Bulk Bag Production Featuring User-Friendly Control SystemNegotiableMOQ: 1 Set

-

Heavy-Duty PP Woven Sack Making Machinery With Energy-Efficient Design and Low MaintenanceNegotiableMOQ: 1 Set

-

Multi-Function PP Woven Bag Production Equipment With Integrated Cutting and Sealing TechnologyNegotiableMOQ: 1 Set

-

Reliable PP Woven Sack Assembly Line Offering High Output Capacity and Consistent QualityNegotiableMOQ: 1 Set

-

Eco-Friendly PP Woven Sack Manufacturing Machine Using Recyclable Polypropylene MaterialsNegotiableMOQ: 1 Set

-

High Speed PP Woven Sack Making Unit for Durable Packaging Solutions in Agricultural SectorNegotiableMOQ: 1 Set

-

PP Woven Bag Manufacturing Equipment With Advanced Control System and Customizable SizesNegotiableMOQ: 1 Set

-

Industrial Woven Polypropylene Bag Production Line for Food and AgricultureNegotiableMOQ: 1 Set

-

Turnkey Woven Bag Production Solution With Customizable Capacity and DimensionsNegotiableMOQ: 1 Set

-

Integrated Woven Bag Production Line Featuring Edge Trimming and Bottom SewingNegotiableMOQ: 1 Set