Advanced Circular Loom for Jumbo Bag Making With Electronic Control Panel

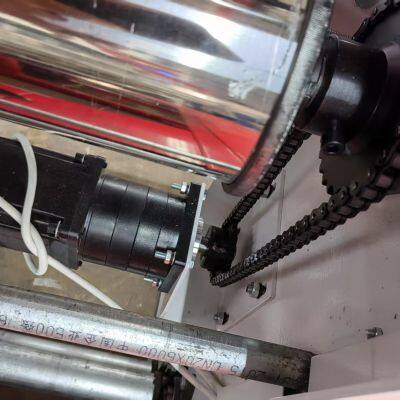

As a specialized manufacturer of industrial weaving equipment, Xuzhou Guozi Intelligent Technology leverages its Jiangsu-based engineering expertise to deliver the Advanced Circular Loom for Jumbo Bag Making. This precision machinery addresses critical production challenges in Flexible Intermediate Bulk Container (FIBC) manufacturing, enabling fabricators to achieve consistent output with reduced operational costs. Our electronic-controlled solution integrates robust mechanical design with intelligent automation, specifically engineered for high-tensile polypropylene weaving applications.

The circular loom incorporates several industry-leading features that enhance production efficiency:

- Precision Electronic Control Panel - Real-time monitoring of weaving tension and speed parameters

- Multi-shuttle Configuration - Options for 4, 6 or 8 shuttles to match production volume requirements

- Adaptive Braking System - Automatic thread break detection with immediate shutdown

- Modular Design - Quick-change components for reduced maintenance downtime

Technical specifications demonstrate the machine's capability for industrial-scale operations:

| Parameter | Specification |

|---|---|

| Weaving Diameter Range | 1200-2500 mm |

| Fabric Weight Capacity | 70-220 g/m² |

| Maximum Weaving Speed | 150 rpm |

| Yarn Compatibility | 500-2500 denier |

| Motor Power | 7.5 kW (standard) |

Operational advantages translate directly to customer benefits:

- 25% Higher Output compared to conventional mechanical looms through optimized shuttle movement

- 15% Material Savings achieved via precision tension control minimizing yarn waste

- Reduced Skill Dependency with automated fault diagnosis and visual alerts

- Future-Proof Design allowing firmware upgrades for new fabric patterns

Backed by our technical center in Xuzhou's industrial hub, we provide comprehensive support including on-site installation supervision and operator training programs. The machinery's modular construction ensures component availability for 10+ years, protecting your production continuity. Over 120 FIBC manufacturers across Southeast Asia currently utilize our circular looms for 24/7 operations, achieving ROI within 14-18 months through consistent fabric quality and reduced rejection rates.

FAQ Section

Q: What maintenance intervals are required?

A: Daily lubrication points and quarterly bearing inspections are recommended, with full service manuals provided.

Q: Can the machine weave UV-stabilized fabrics?

A: Yes, the tension control system accommodates specialty yarns including UV-treated and anti-static variants.

Q: Is technical training included?

A: We provide 5-day onsite training covering operation, basic troubleshooting, and safety procedures.

Q: What's the lead time for delivery?

A: Standard configurations ship within 45 days after order confirmation, subject to production schedule.

Q: How is fabric quality monitored during production?

A: The PLC system records weaving density consistency and alerts operators to deviations exceeding ±2% tolerance.

Q: Can existing mechanical looms be upgraded with this control system?

A: Retrofit kits are available for selected models - please provide your current machine details for evaluation.

Send Inquiry to This Supplier

You May Also Like

-

High-Speed FIBC Circular Loom for PP Woven Bags With Automatic Control SystemNegotiableMOQ: 1 Set

-

Energy Saving Circular Loom Machine for FIBC and Big Bag ManufacturingNegotiableMOQ: 1 Set

-

Precision Circular Loom Machine for High-Quality FIBC Woven FabricNegotiableMOQ: 1 Set

-

Automatic Circular Loom Machine for Woven Sacks and FIBC Jumbo Bags ManufacturingNegotiableMOQ: 1 Set

-

Advanced Circular Loom Weaving Machine for Jumbo Bulk Bag ProductionNegotiableMOQ: 1 Set

-

High-Speed FIBC Circular Loom Machine for Jumbo Bag Production With 4 Shuttles SystemNegotiableMOQ: 1 Set

-

High-Performance FIBC Circular Loom for PP Woven Bag Production With Advanced Weaving TechnologyNegotiableMOQ: 1 Set

-

Efficient FIBC Circular Loom Machinery With Low Maintenance Design for Continuous Woven Bag OutputNegotiableMOQ: 1 Set

-

Energy-Saving Circular Loom Equipment for FIBC and Jumbo Bag Manufacturing IndustriesNegotiableMOQ: 1 Set

-

Versatile Circular Loom for Bulk Bag Production Featuring User-Friendly Control SystemNegotiableMOQ: 1 Set