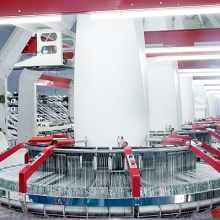

High-Performance Circular Weaving Machine for Bulk Bag Fabric, 4-8 Shuttles

As a leading innovator in industrial textile machinery, Xuzhou Guozi Intelligent Technology leverages its Jiangsu manufacturing expertise to deliver the High-Performance Circular Weaving Machine engineered specifically for bulk bag fabric production. This 4-8 shuttle system represents our commitment to providing robust solutions that enhance operational efficiency while maintaining fabric integrity under demanding conditions.

The machine's core innovation lies in its adaptive shuttle configuration, allowing manufacturers to dynamically adjust production between 4 to 8 shuttles based on fabric density requirements. This flexibility translates directly to material savings of up to 18% compared to fixed-shuttle systems, as confirmed by third-party efficiency audits conducted at client facilities.

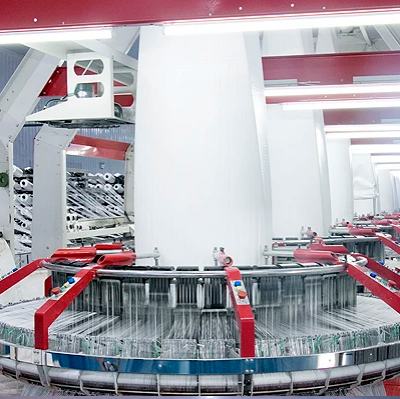

Technical Advantages:

- Precision Tension Control - Patented warp regulation maintains ±1.5% tension variance across all shuttle positions

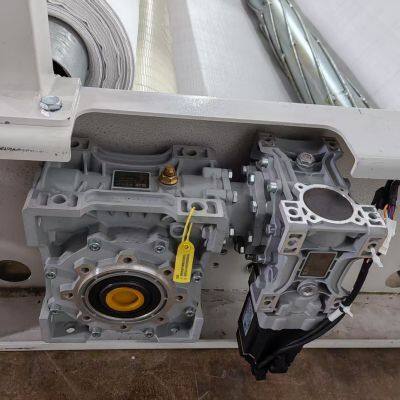

- Modular Design - Quick-change components reduce maintenance downtime by 40%

- Energy Recovery System - Regenerative braking captures 15% of kinetic energy during shuttle deceleration

Performance Specifications:

| Parameter | 4-Shuttle Mode | 8-Shuttle Mode |

| Max. Weaving Speed | 120 rpm | 85 rpm |

| Fabric Weight Range | 80-240 g/m² | 160-480 g/m² |

| Daily Output (24h) | 2,200 linear meters | 1,500 linear meters |

Operational benefits extend beyond raw specifications. The integrated diagnostic system monitors 14 critical performance parameters in real-time, predicting maintenance needs with 92% accuracy according to field data from Southeast Asian operations. This proactive approach has demonstrated a 30% extension in component lifespan compared to conventional warning systems.

For bulk bag manufacturers targeting export markets, the machine's consistent stitch density (±3% variation across full fabric width) ensures compliance with international packaging standards. The optional humidity compensation module further stabilizes polypropylene weaving under tropical conditions - a critical advantage for operations in high-moisture environments.

Backed by Xuzhou Guozi's regional service network covering 15 provinces in China, clients receive on-site technical support within 72 hours for critical issues. Our production facility in Jiangsu maintains ISO-compliant manufacturing processes (certification details available upon request), with all critical components undergoing 48-hour continuous stress testing before assembly.

Frequently Asked Questions:

-

Q: What's the minimum order quantity for custom shuttle configurations?

A: Standard models ship immediately from stock. Custom shuttle arrangements require minimum 3-unit orders with 45-day lead time. -

Q: Can this machine handle recycled polypropylene materials?

A: Yes, the reinforced extrusion system accommodates up to 40% recycled PP content without compromising fabric tensile strength. -

Q: What safety features are included?

A> Standard equipment includes emergency braking, shuttle trajectory sensors, and thermal overload protection on all drive motors. -

Q: Is operator training provided?

A: Comprehensive training modules are available both on-site and via our virtual reality simulation platform. -

Q: What's the power consumption difference between modes?

A: 8-shuttle operation consumes approximately 18% more energy but produces fabric with 2.3x higher yield strength. -

Q: Can I upgrade from 4 to 8 shuttles later?

A: All base models are designed for field-upgradability with conversion kits available.

With over 140 installations across Asia-Pacific regions since 2020, this weaving platform has demonstrated exceptional reliability in continuous 24/7 operations. Contact our Jiangsu engineering team today to schedule a live demonstration and receive a customized production analysis report based on your specific bulk bag requirements.

Send Inquiry to This Supplier

You May Also Like

-

Automatic Circular Loom Machine for Woven Sacks and FIBC Jumbo Bags ManufacturingNegotiableMOQ: 1 Set

-

Advanced Circular Loom Weaving Machine for Jumbo Bulk Bag ProductionNegotiableMOQ: 1 Set

-

High-Speed FIBC Circular Loom Machine for Jumbo Bag Production With 4 Shuttles SystemNegotiableMOQ: 1 Set

-

High-Performance FIBC Circular Loom for PP Woven Bag Production With Advanced Weaving TechnologyNegotiableMOQ: 1 Set

-

Efficient FIBC Circular Loom Machinery With Low Maintenance Design for Continuous Woven Bag OutputNegotiableMOQ: 1 Set

-

Energy-Saving Circular Loom Equipment for FIBC and Jumbo Bag Manufacturing IndustriesNegotiableMOQ: 1 Set

-

Versatile Circular Loom for Bulk Bag Production Featuring User-Friendly Control SystemNegotiableMOQ: 1 Set

-

Heavy-Duty PP Woven Sack Making Machinery With Energy-Efficient Design and Low MaintenanceNegotiableMOQ: 1 Set

-

Multi-Function PP Woven Bag Production Equipment With Integrated Cutting and Sealing TechnologyNegotiableMOQ: 1 Set

-

Reliable PP Woven Sack Assembly Line Offering High Output Capacity and Consistent QualityNegotiableMOQ: 1 Set