FIBC Circular Loom for Construction Material Packaging With Heavy-Duty Frame

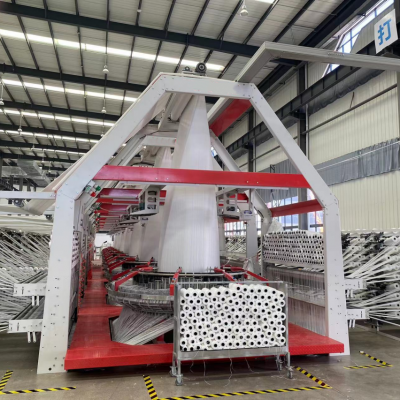

We at Xuzhou Guozi Intelligent Technology Co., Ltd., located in Xuzhou, Jiangsu, China, proudly introduce our FIBC Circular Loom designed specifically for construction material packaging. This innovative machine features a heavy-duty frame that ensures exceptional durability and reliability in demanding industrial environments. As a leading manufacturer in intelligent technology, we focus on delivering solutions that enhance packaging efficiency and reduce operational costs. Our loom is engineered to handle the rigorous demands of bulk bag production, making it an ideal choice for businesses seeking high-performance equipment. With our commitment to quality and innovation, this product stands out for its robust construction and user-friendly design.

The FIBC Circular Loom offers numerous advanced features and benefits tailored for construction material applications. Key characteristics include:

- High-Speed Weaving: Capable of operating at optimized speeds to increase production output, reducing labor costs and improving throughput.

- Durable Construction: Built with a heavy-duty steel frame that resists wear and tear, ensuring long-term reliability even under continuous use.

- Customizable Settings: Adjustable weaving parameters allow for flexibility in producing various FIBC bag sizes and types, catering to specific packaging needs.

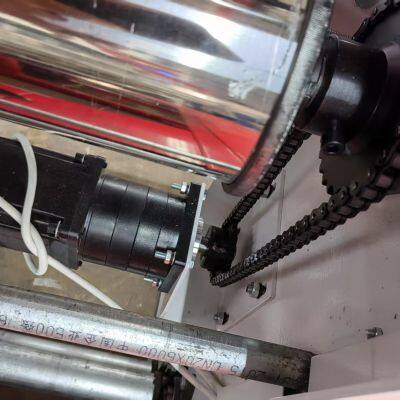

- Energy Efficiency: Designed with an electric motor that minimizes power consumption, lowering operational expenses and supporting sustainable practices.

- Ease of Operation: Features intuitive controls and semi-automatic or automatic options, simplifying training and reducing downtime for maintenance.

Technical specifications highlight the precision and capability of this loom. Below is a summary of core parameters:

| Parameter | Value |

| Weaving Width | Up to 2000 mm (customizable) |

| Operating Speed | 100-150 rpm |

| Power Consumption | Approximately 5.5 kW |

| Frame Material | Reinforced steel |

| Weight Capacity | Suitable for heavy-duty bags |

These specifications translate into tangible advantages for clients. For instance, the high weaving speed accelerates production cycles, enabling faster turnaround on orders. The customizable width allows adaptation to different construction materials like cement, sand, or aggregates, ensuring versatile application. Additionally, the robust frame minimizes breakdowns, leading to reduced maintenance costs and higher uptime. Overall, this loom helps businesses achieve cost savings through efficient resource use and improved bag quality, enhancing their competitiveness in the packaging market.

Backed by Xuzhou Guozi Intelligent Technology Co., Ltd.'s expertise from Xuzhou, Jiangsu, China, our FIBC Circular Loom represents years of innovation in industrial machinery. We prioritize customer satisfaction with reliable after-sales support and tailored solutions. This product's heavy-duty design ensures it meets the toughest packaging challenges, offering peace of mind for long-term investments. Reach out to us today to discuss how this loom can optimize your operations—contact our team for a personalized consultation or quote. Invest in efficiency and durability; let us help you elevate your packaging process with our trusted technology.

Frequently Asked Questions (FAQ)

Q: What types of materials can this FIBC Circular Loom handle?

A: The loom is designed for weaving FIBC bags used in packaging construction materials such as cement, sand, gravel, and other aggregates, offering versatility for various industrial needs.

Q: Is the heavy-duty frame suitable for continuous operation?

A: Yes, the reinforced steel frame is built to withstand prolonged use in demanding environments, ensuring durability and minimizing downtime for maintenance.

Q: Can the weaving width be adjusted for different bag sizes?

A: Absolutely, the weaving width is customizable, allowing you to produce bags of various dimensions to meet specific packaging requirements.

Q: What power source is required for this machine?

A: It operates on a standard electric motor, typically requiring 380V power supply, and is designed for energy efficiency to reduce operational costs.

Q: How easy is it to maintain this circular loom?

A: Maintenance is straightforward with accessible components and user-friendly design; regular lubrication and inspections are recommended to ensure optimal performance.

Q: Are there automation options available?

A: Yes, the loom comes in semi-automatic or automatic configurations, providing flexibility based on your production scale and automation preferences.

Q: What is the typical delivery time for this product?

A: Delivery times vary based on order specifications and location; contact us for an estimated timeline tailored to your needs.

Q: Can the machine be customized for specific factory setups?

A: Customization options are available upon request, allowing adaptations to fit unique operational environments or integrate with existing systems.

Send Inquiry to This Supplier

You May Also Like

-

Industrial Circular Weaving Loom for Bulk FIBC Fabric, 4-8 Shuttles ConfigurationNegotiableMOQ: 1 Set

-

Precision Circular Loom for FIBC Material With Automatic Brake SystemNegotiableMOQ: 1 Set

-

High-Performance Circular Weaving Machine for Bulk Bag Fabric, 4-8 ShuttlesNegotiableMOQ: 1 Set

-

Heavy-Duty Circular Loom Machine for Jumbo Bag Production, 170-220cm WidthNegotiableMOQ: 1 Set

-

Robust FIBC Circular Loom Supporting Various PP Woven Bag SpecificationsNegotiableMOQ: 1 Set

-

High-Speed FIBC Circular Loom for PP Woven Bags With Automatic Control SystemNegotiableMOQ: 1 Set

-

Energy Saving Circular Loom Machine for FIBC and Big Bag ManufacturingNegotiableMOQ: 1 Set

-

Precision Circular Loom Machine for High-Quality FIBC Woven FabricNegotiableMOQ: 1 Set

-

Automatic Circular Loom Machine for Woven Sacks and FIBC Jumbo Bags ManufacturingNegotiableMOQ: 1 Set

-

Advanced Circular Loom Weaving Machine for Jumbo Bulk Bag ProductionNegotiableMOQ: 1 Set