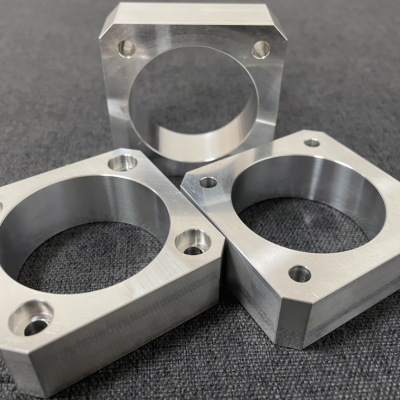

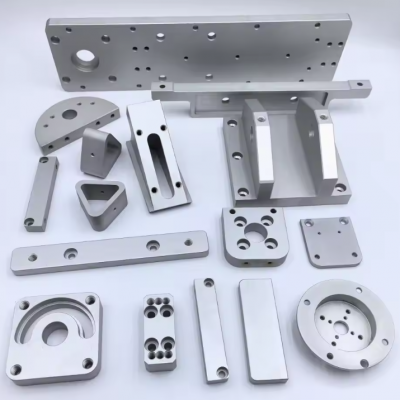

Medical Grade CNC Machining Precision Metal Parts for Surgical Devices

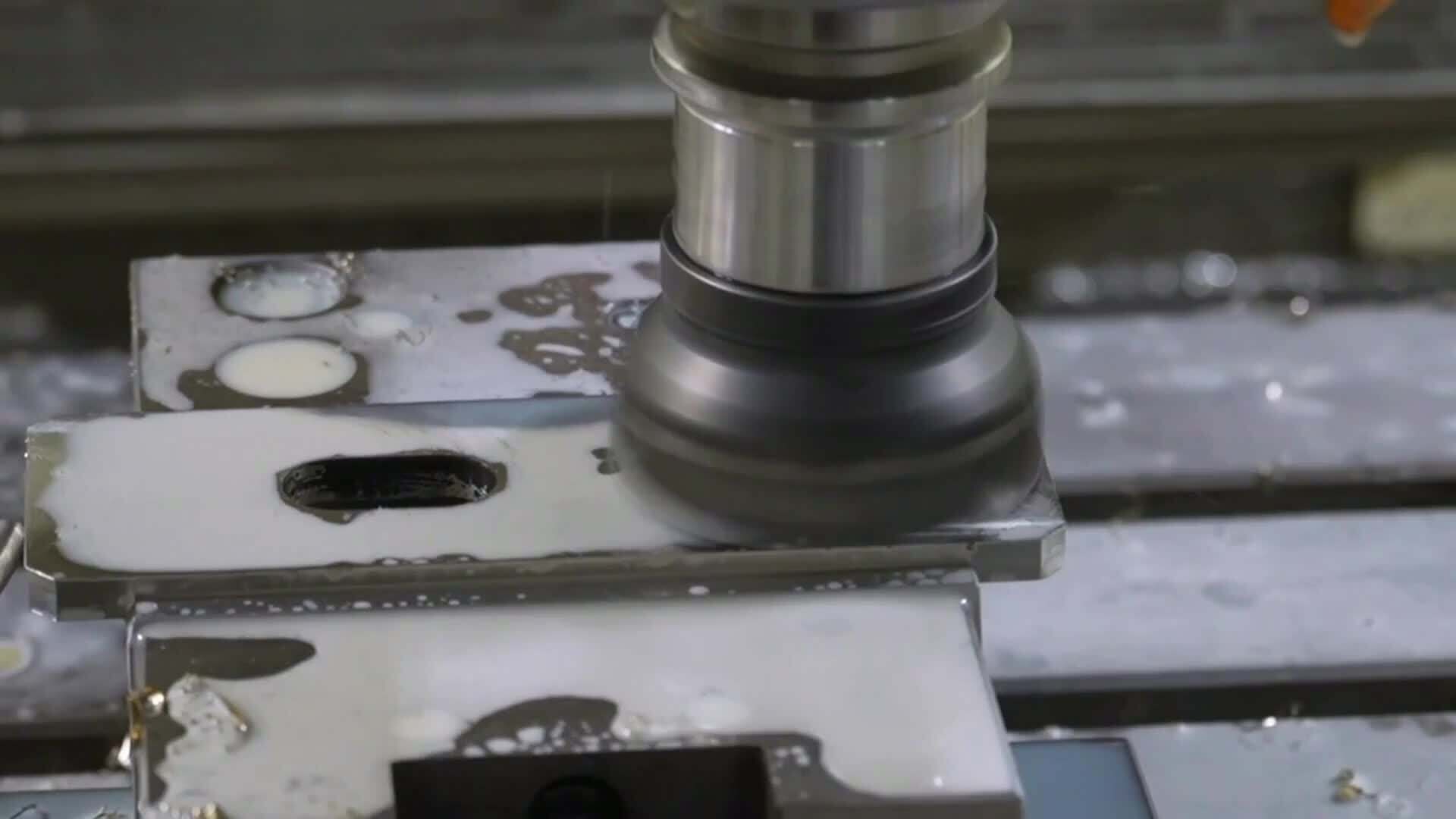

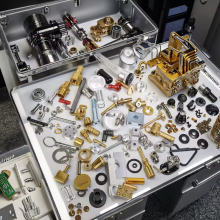

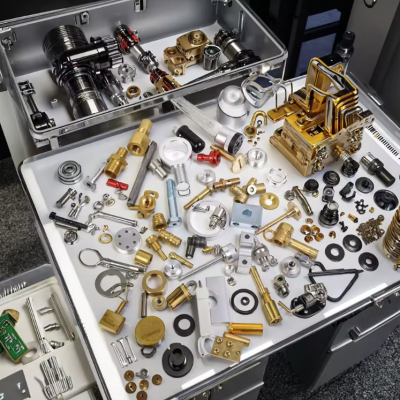

Ningbo Changfeng Mechanical Factory specializes in manufacturing medical-grade precision components for surgical applications, leveraging three decades of machining expertise since our establishment in 1990. Our CNC-machined metal parts meet stringent requirements for biocompatibility and dimensional accuracy, ensuring reliable performance in critical healthcare environments. With extensive export experience across global markets including North America and Europe, we deliver components that enhance surgical device functionality while maintaining rigorous quality control throughout production.

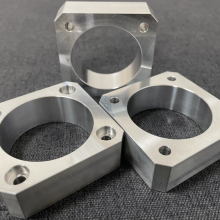

Our manufacturing capabilities focus on creating parts that integrate seamlessly with various surgical systems, from minimally invasive tools to orthopedic implants. The advanced CNC technology we employ allows for complex geometries and ultra-tight tolerances required in medical applications, while our material selection prioritizes corrosion resistance and sterilization compatibility. Each component undergoes thorough inspection to verify compliance with medical device specifications before shipment.

Key technical specifications include:

- Material options optimized for specific surgical applications

- Surface treatments ensuring microbial resistance

- Dimensional accuracy maintained across production batches

- Customizable features based on device requirements

The following table outlines standard capabilities for common surgical components:

| Feature | Capability | Medical Application |

|---|---|---|

| Tolerance Range | ±0.005mm | Implant fitting |

| Surface Roughness | Ra 0.2μm | Reduced bacterial adhesion |

| Material Thickness | 0.5-50mm | Instrument handles to structural components |

Clients benefit from our vertically integrated manufacturing process that maintains consistency across production runs while accommodating specialized requests. The elimination of secondary finishing operations reduces potential contamination risks, and our quality assurance protocols include material traceability documentation. By partnering with surgical device manufacturers globally, we've developed solutions that address challenges in laparoscopy, neurosurgery, and diagnostic equipment.

With extensive experience supplying medical OEMs across 15+ international markets, we understand the critical nature of component reliability in healthcare settings. Our production facility in Ningbo maintains dedicated medical machining cells with environmental controls, and we offer flexible order quantities from prototyping to volume production. Contact our engineering team to discuss how our precision machining capabilities can enhance your surgical device performance while ensuring regulatory compliance.

Frequently Asked Questions

Q: What materials do you recommend for implantable components?

A: We typically suggest titanium alloys or medical-grade stainless steel, selected based on specific biocompatibility requirements and sterilization methods.

Q: Can you accommodate custom design specifications?

A: Yes, we provide design consultation services and can machine components according to provided CAD drawings or samples.

Q: What quality documentation do you provide?

A> We supply material certifications, dimensional inspection reports, and surface finish verification for all medical components.

Q: How do you ensure part cleanliness for medical use?

A: Our post-machining processes include ultrasonic cleaning in controlled environments and specialized packaging.

Q: What is your typical production lead time?

A: Standard components ship within 15-30 days, with expedited options available for urgent requirements.

Send Inquiry to This Supplier

You May Also Like

-

Industrial CNC Machining Services for Automotive and Aerospace Industry ComponentsNegotiableMOQ: 10 Units

-

Reliable CNC Machining Services Offering Cost-Effective Solutions for Electronics EnclosuresNegotiableMOQ: 10 Units

-

High-Precision CNC Machining Services With Tight Tolerances for Complex Industrial DesignsNegotiableMOQ: 10 Units

-

Advanced CNC Machining Services for Rapid Prototyping Applications in EngineeringNegotiableMOQ: 10 Units

-

Fast Turnaround CNC Machining Services With On-Time Delivery for Urgent ProjectsNegotiableMOQ: 10 Units

-

Custom-Sized CNC Machining Services Compatible With CAD Files for Metal FabricationNegotiableMOQ: 10 Units

-

Professional CNC Machining Services for Aluminum, Steel, and Plastic Components With Custom SizesNegotiableMOQ: 10 Units

-

Versatile CNC Machining Services for Various Materials Including Titanium and Composite PartsNegotiableMOQ: 10 Units

-

Efficient CNC Machining Services for Mass Production Batches and Small Quantity OrdersNegotiableMOQ: 10 Units

-

Hot Selling CNC Milling Turning Customized Metal CNC Machining Services Non-standard Parts Turning Milling Composite ProcessingUS$ 10MOQ: 10 Units