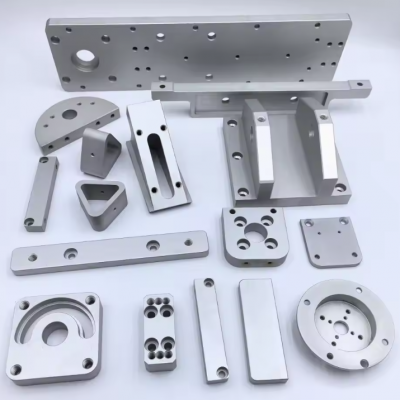

CNC Machining Precision Metal Parts for Medical Devices and Surgical Instruments Industry

Ningbo Changfeng Mechanical Factory specializes in CNC machining precision metal parts tailored for the medical devices and surgical instruments industry, ensuring exceptional accuracy and reliability for critical healthcare applications. Our components are engineered to meet stringent quality standards, providing durable solutions that enhance the performance and safety of medical equipment. With decades of manufacturing expertise since 1990, we deliver custom parts that support innovation in global healthcare markets. Trust our high-precision machining to reduce operational risks and improve patient outcomes in demanding medical environments.

Our CNC machining process leverages advanced technology to produce metal parts with micron-level tolerances, ideal for intricate surgical tools and medical devices. Key features include:

- Material versatility: We use biocompatible materials like stainless steel, titanium, and aluminum, which are corrosion-resistant and suitable for sterilization.

- High accuracy: Achieve tolerances as tight as ±0.005 mm, ensuring parts fit perfectly in assemblies and reduce wear.

- Custom design capabilities: Parts are fully customizable in size, shape, and configuration to match specific device requirements.

- Surface finish options: Available finishes include polishing and coating for enhanced durability and hygiene.

Technical specifications are adaptable to client needs, with common parameters outlined below for reference. This flexibility allows for seamless integration into various medical applications, from implantable devices to diagnostic instruments.

| Parameter | Typical Range | Notes |

|---|---|---|

| Material Options | Stainless Steel, Titanium, Aluminum | Biocompatible and sterilizable |

| Tolerance | ±0.005 mm to ±0.02 mm | Adjustable based on complexity |

| Size Range | Customizable | From small components to larger assemblies |

| Surface Roughness | Ra 0.4 μm to 1.6 μm | Polished or coated for medical use |

Advantages of our CNC machined parts include reduced production lead times, cost efficiency through minimized waste, and enhanced product longevity. Clients benefit from improved device reliability, lower maintenance costs, and compliance with industry standards, making our solutions ideal for OEMs and suppliers in the medical field. For instance, our precision components help surgical instruments maintain sterility and accuracy, directly contributing to safer procedures and better healthcare delivery.

Partner with Ningbo Changfeng Mechanical Factory for CNC machined parts that elevate your medical devices with uncompromising quality and innovation. Our global reach across markets like North America, Europe, and Asia ensures timely delivery and support for your projects. Contact us today to discuss custom requirements and experience how our expertise can optimize your supply chain. Take the next step in advancing medical technology by requesting a quote or consultation for tailored solutions.

Frequently Asked Questions (FAQ)

Q: What materials are commonly used for these medical parts?

A: We typically use stainless steel, titanium, or aluminum, all customizable for biocompatibility and sterilization needs.

Q: Can I request custom sizes and tolerances?

A: Yes, dimensions and tolerances are fully customizable based on your specifications and application requirements.

Q: What is the typical lead time for production?

A: Lead times vary with order complexity but are generally efficient; specific timelines are available upon request.

Q: Are there minimum order quantities?

A: MOQs are flexible and can be discussed to accommodate both small prototypes and large-scale production runs.

Q: How do you ensure quality for medical applications?

A: Our processes include rigorous inspections to ensure parts meet industry standards for precision and safety.

Q: Do you offer surface finishing options?

A: Yes, various finishes like polishing or coating are available to enhance durability and hygiene.

Q: Can parts be used in implantable medical devices?

A: With appropriate material selection and customization, our parts are suitable for a wide range of applications, including implants.

Send Inquiry to This Supplier

You May Also Like

-

CNC Machining Precision Metal Parts for Energy Sector and Renewable Industry ComponentsUS$ 12MOQ: 10 Units

-

CNC Machining Precision Metal Parts Compatible With Automotive and Aerospace SystemsUS$ 12MOQ: 10 Units

-

High-Precision CNC Machining Precision Metal Parts for Durable and Long-Lasting ApplicationsUS$ 12MOQ: 10 Units

-

CNC Machining Precision Metal Parts in Custom Sizes and Materials for Industrial EquipmentUS$ 12MOQ: 10 Units

-

Hot Selling CNC Milling Turning Customized Metal CNC Machining Services Non-standard Parts Turning Milling Composite ProcessingUS$ 10MOQ: 10 Units

-

High Grade Wholesale CNC Machining Precision Metal Parts Oem Odm Customized Aluminum Alloy Milling PartsUS$ 11MOQ: 10 Units

-

High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 Units

-

Advanced OEM CNC Machining Service for Stainless Steel Aluminum Brass Bronze & Copper Parts Including BroachingUS$ 13MOQ: 10 Units

-

High Precision CNC Lathe Turning Milling Machining Parts Custom Quality Aluminum Stainless Steel Brass Fabrication CNC ServicesUS$ 14MOQ: 10 Units

-

CNC Stainless Steel Cooling Plate 3D Printing Gear Ball Copper Screw Stamping Anodized Aluminum Ring Parts Cnc Machining ServiceUS$ 15MOQ: 10 Units