Reliable CNC Machining Services Offering Cost-Effective Solutions for Electronics Enclosures

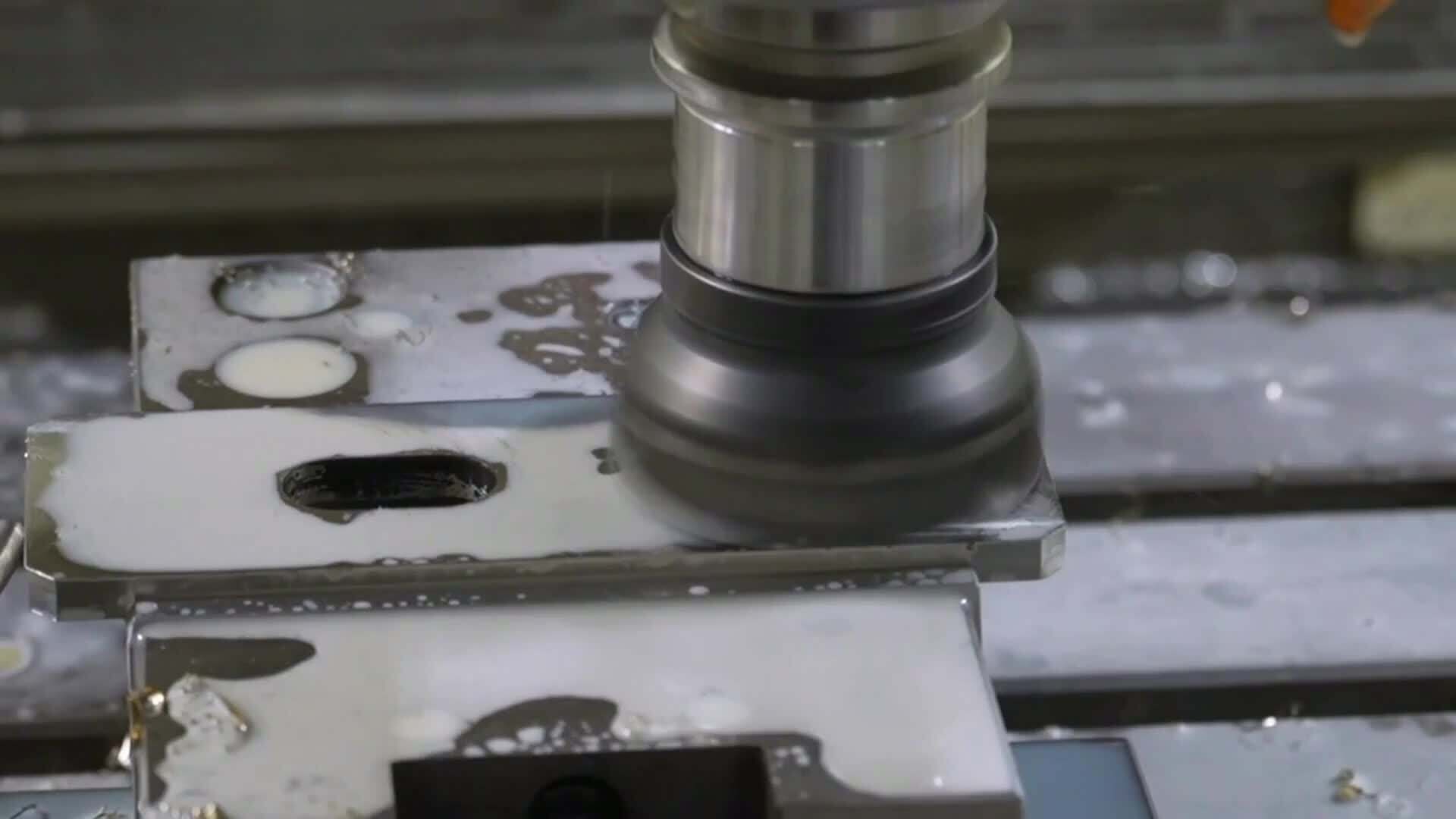

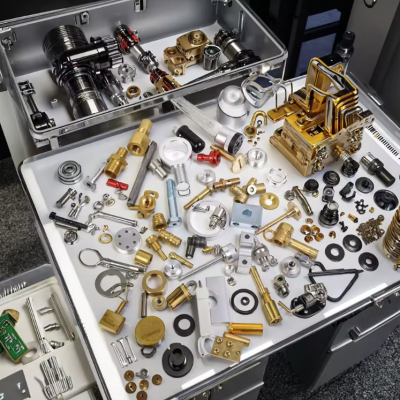

Ningbo Changfeng Mechanical Factory delivers precision CNC machining services specifically engineered for electronics enclosures, combining three decades of manufacturing expertise with cost-effective solutions for global clients. Our ISO-certified facility (certification available upon request) utilizes advanced 4-axis and 5-axis machining centers to produce enclosures that meet exacting industry standards while optimizing production efficiency. With an annual export value exceeding $10 million, we serve diverse markets from North America to Oceania, ensuring your electronic components receive optimal protection through our rigorously tested enclosures.

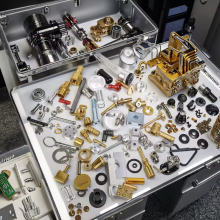

Key technical advantages include:

- Advanced Thermal Management: Engineered ventilation patterns prevent overheating

- EMI/RFI Shielding: Customizable solutions for electromagnetic interference

- IP-Rated Protection: Options for dust/water resistance (IP54-IP68)

- Rapid Prototyping: Functional samples within 72 hours

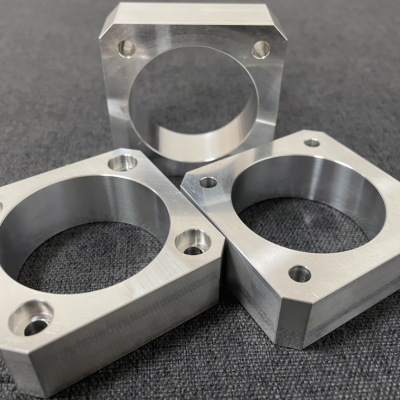

| Parameter | Standard Range | Custom Options |

|---|---|---|

| Wall Thickness | 1.5mm - 6mm | Up to 20mm |

| Maximum Dimensions | 500×400×200mm | 1000×800×500mm |

| Threaded Inserts | M3 - M8 | Custom sizes |

Our value proposition centers on eliminating common enclosure pain points:

"By integrating design-for-manufacturing analysis at the quotation stage, we identify potential production challenges before machining begins, reducing costly revisions. This proactive approach, combined with our vertically integrated supply chain, typically delivers 15-25% cost savings compared to standard industry rates for medium-volume orders."

Clients benefit from our comprehensive quality assurance protocol that includes:

- First-article inspection reports with dimensional verification

- Material traceability documentation

- Surface roughness testing (Ra 0.8μm - 3.2μm achievable)

- Functional testing of moving components

Partner with our Ningbo-based facility established in 1990 to leverage our cross-industry experience serving telecommunications, medical device, and industrial automation sectors. Request a complimentary design optimization review today to discover how our machining solutions can enhance your product's reliability while reducing total ownership costs.

Frequently Asked Questions

Q: What file formats do you accept for enclosure designs?

A: We process all major CAD formats including STEP, IGES, SolidWorks, and AutoCAD files. Our engineering team can convert other formats upon request.

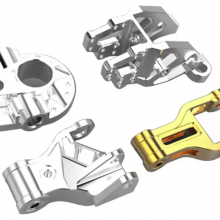

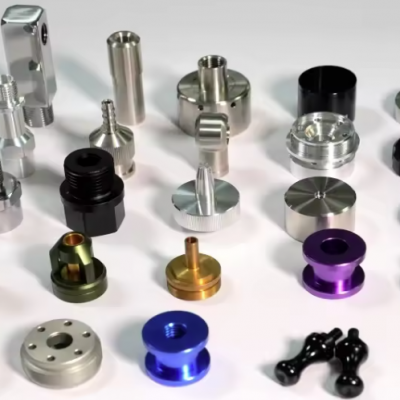

Q: Do you provide finishing services for machined enclosures?

A: Yes, our in-house finishing department offers anodizing, powder coating, silk screening, and laser marking services to create production-ready components.

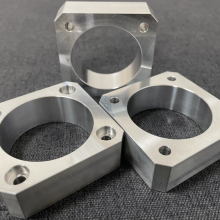

Q: How do you ensure dimensional accuracy for tight-tolerance enclosures?

A: Our climate-controlled machining environment and daily calibration of inspection equipment maintain ±0.005mm accuracy. Temperature compensation protocols are implemented for critical dimensions.

Q: Can you accommodate RoHS-compliant materials?

A: Absolutely, we regularly machine compliant aluminum alloys and engineering plastics. Material certifications are provided with shipments.

Q: What shipping options are available for international clients?

A: We coordinate door-to-door shipping via air or sea freight with DDP options available. Packaging includes custom foam inserts to prevent transit damage.

Send Inquiry to This Supplier

You May Also Like

-

Versatile CNC Machining Services for Various Materials Including Titanium and Composite PartsNegotiableMOQ: 10 Units

-

Efficient CNC Machining Services for Mass Production Batches and Small Quantity OrdersNegotiableMOQ: 10 Units

-

Hot Selling CNC Milling Turning Customized Metal CNC Machining Services Non-standard Parts Turning Milling Composite ProcessingUS$ 10MOQ: 10 Units

-

High Grade Wholesale CNC Machining Precision Metal Parts Oem Odm Customized Aluminum Alloy Milling PartsUS$ 11MOQ: 10 Units

-

High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 Units

-

Advanced OEM CNC Machining Service for Stainless Steel Aluminum Brass Bronze & Copper Parts Including BroachingUS$ 13MOQ: 10 Units

-

High Precision CNC Lathe Turning Milling Machining Parts Custom Quality Aluminum Stainless Steel Brass Fabrication CNC ServicesUS$ 14MOQ: 10 Units

-

CNC Stainless Steel Cooling Plate 3D Printing Gear Ball Copper Screw Stamping Anodized Aluminum Ring Parts Cnc Machining ServiceUS$ 15MOQ: 10 Units

-

CNC Milling Parts Stainless Steel/Aluminum Alloy Compatible With CNC Machines for High-Accuracy Industrial FabricationUS$ 14MOQ: 10 Units

-

Precision CNC Milling Parts Aluminum/Steel/Brass in Various Sizes for Industrial Applications & Machinery FabricationUS$ 14MOQ: 10 Units