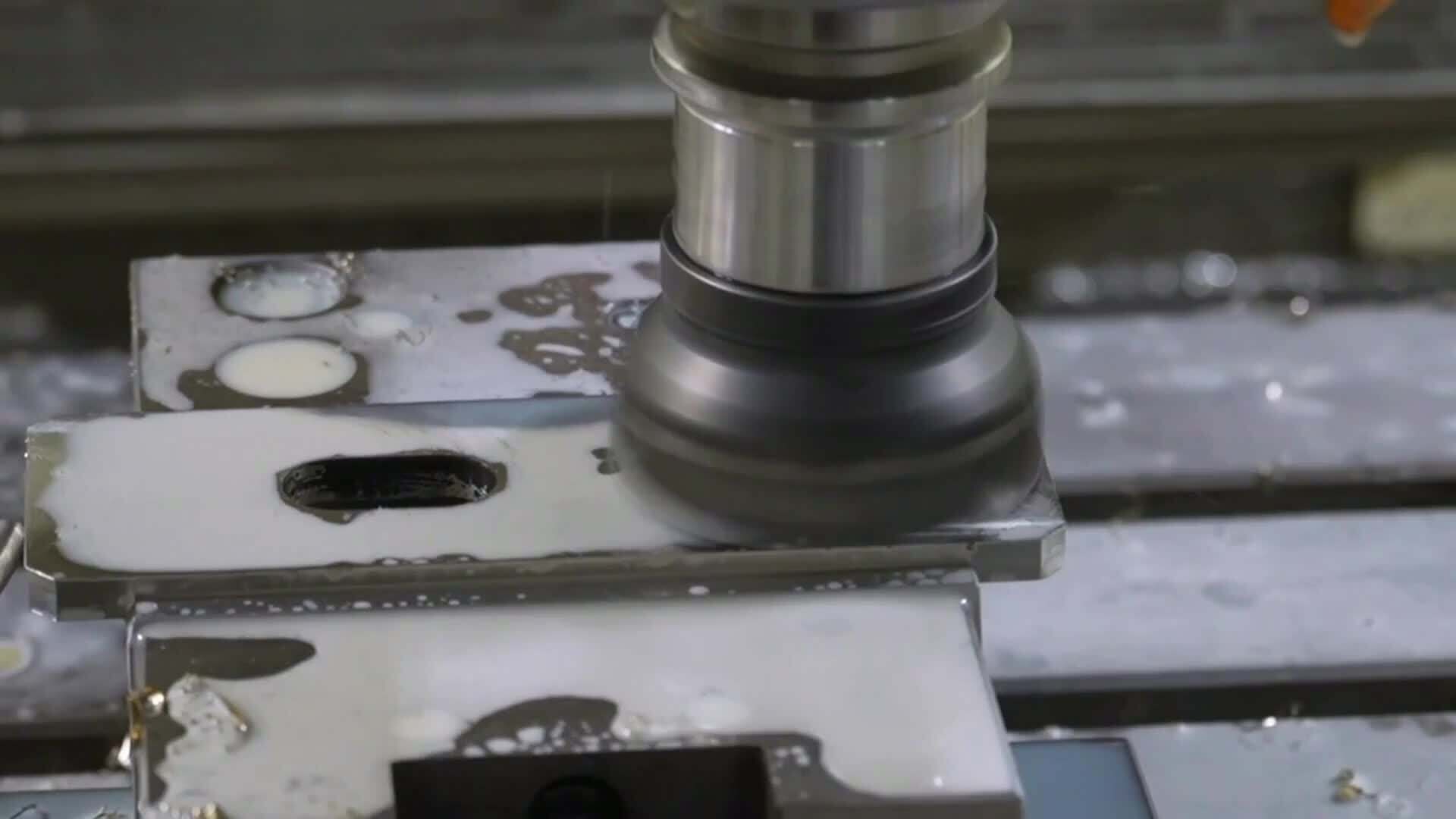

Industrial CNC Machining Precision Metal Parts for Heavy Machinery Applications

Ningbo Changfeng Mechanical Factory delivers high-precision CNC machined metal parts specifically engineered for heavy machinery applications, ensuring durability and reliability in demanding industrial environments. Established in 1990, our factory leverages over three decades of manufacturing expertise to produce components that enhance equipment performance and longevity. With an annual export value of US$10 million to US$50 million, we serve diverse global markets including North America, Europe, Asia, and beyond, providing tailored solutions for construction, mining, and agricultural machinery. Our commitment to quality and precision machining helps clients reduce downtime and improve operational efficiency. Trust in our proven capabilities to meet your exacting standards for metal parts that withstand rigorous use.

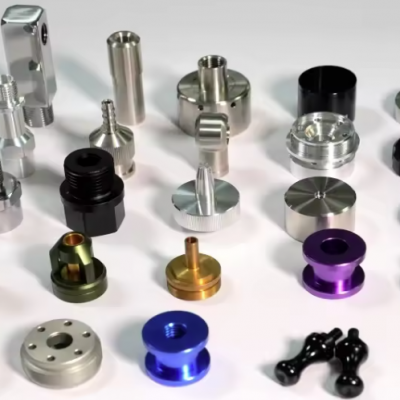

Our industrial CNC machining services offer numerous advantages, starting with exceptional precision that ensures tight tolerances for seamless integration into heavy machinery. Components are fabricated from robust materials like steel and aluminum, chosen for their strength and resistance to wear and corrosion. The CNC process allows for complex geometries and intricate designs, enabling customization to fit unique applications—whether for hydraulic systems, engine mounts, or structural frames. Clients benefit from reduced production errors and enhanced part longevity, leading to lower maintenance costs and improved machine uptime. Additionally, our scalable production capabilities support both small-batch prototypes and high-volume orders, ensuring flexibility across projects.

Advanced Technology: Utilizing state-of-the-art CNC machines, we achieve micron-level accuracy for consistent part quality.

Material Versatility: Work with a range of metals including alloys, tailored to specific environmental and load requirements.

Customization Options: Parts can be designed to exact specifications, with modifications available upon request.

Quality Assurance: Rigorous inspection protocols ensure each component meets industry standards for performance.

Global Logistics: Efficient shipping and handling to major markets worldwide, minimizing lead times.

Technical specifications are critical for informed decision-making; below is a summary of key parameters for our precision metal parts:

| Parameter | Specification |

|---|---|

| Material Options | Steel, Aluminum, Alloy |

| Dimensional Range | 1mm to 1000mm (Customizable) |

| Tolerance Levels | ±0.01mm to ±0.05mm |

| Surface Finish | Ra 0.8μm to 3.2μm |

| Production Lead Time | 2-4 weeks (Standard) |

| Typical Applications | Gears, Brackets, Shafts |

The advantages of choosing our CNC machined parts extend beyond technical specs; they translate into tangible benefits for your operations. For instance, precision manufacturing minimizes waste and rework, optimizing resource use and reducing costs. Enhanced durability means parts last longer under high-stress conditions, such as in mining or construction machinery, leading to fewer replacements and lower lifecycle expenses. Our focus on customization ensures parts integrate perfectly with existing systems, improving overall equipment efficiency. Clients also gain from our responsive support, with dedicated teams assisting from design to delivery, ensuring a smooth procurement process.

Partner with Ningbo Changfeng for precision metal parts that elevate your heavy machinery performance. Our extensive experience and global reach make us a reliable supplier for industries worldwide. Contact us today to discuss your specific needs and receive a customized quotation. We look forward to collaborating on solutions that drive your success.

Frequently Asked Questions

Q: What materials are commonly used for these precision parts?

A: We typically use metals like steel, aluminum, and alloys, which can be selected based on application requirements such as strength or corrosion resistance.

Q: Can you accommodate custom designs and sizes?

A: Yes, our CNC machining capabilities allow for full customization; simply provide your specifications or drawings for a tailored solution.

Q: What is the standard lead time for orders?

A: Standard production takes 2-4 weeks, but this can vary with complexity and volume; contact us for project-specific timelines.

Q: Do you offer certifications for your parts?

A: Certifications are available upon request and can be discussed during the quotation process to meet your compliance needs.

Q: How do I place an order or request a quote?

A: Reach out via our contact channels with details like quantities and specifications; we'll respond promptly with pricing and guidance.

Q: What industries do you primarily serve?

A: Our parts are designed for heavy machinery sectors, including construction, mining, agriculture, and industrial equipment manufacturing.

Q: Are there options for surface treatments or finishes?

A: Yes, various finishes like polishing or coating can be applied; discuss your requirements for enhanced protection or aesthetics.

Send Inquiry to This Supplier

You May Also Like

-

Custom-Sized CNC Machining Services Compatible With CAD Files for Metal FabricationNegotiableMOQ: 10 Units

-

Professional CNC Machining Services for Aluminum, Steel, and Plastic Components With Custom SizesNegotiableMOQ: 10 Units

-

Versatile CNC Machining Services for Various Materials Including Titanium and Composite PartsNegotiableMOQ: 10 Units

-

Efficient CNC Machining Services for Mass Production Batches and Small Quantity OrdersNegotiableMOQ: 10 Units

-

Hot Selling CNC Milling Turning Customized Metal CNC Machining Services Non-standard Parts Turning Milling Composite ProcessingUS$ 10MOQ: 10 Units

-

High Grade Wholesale CNC Machining Precision Metal Parts Oem Odm Customized Aluminum Alloy Milling PartsUS$ 11MOQ: 10 Units

-

High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 Units

-

Advanced OEM CNC Machining Service for Stainless Steel Aluminum Brass Bronze & Copper Parts Including BroachingUS$ 13MOQ: 10 Units

-

High Precision CNC Lathe Turning Milling Machining Parts Custom Quality Aluminum Stainless Steel Brass Fabrication CNC ServicesUS$ 14MOQ: 10 Units

-

CNC Stainless Steel Cooling Plate 3D Printing Gear Ball Copper Screw Stamping Anodized Aluminum Ring Parts Cnc Machining ServiceUS$ 15MOQ: 10 Units