Advanced CNC Machining Services for Rapid Prototyping Applications in Engineering

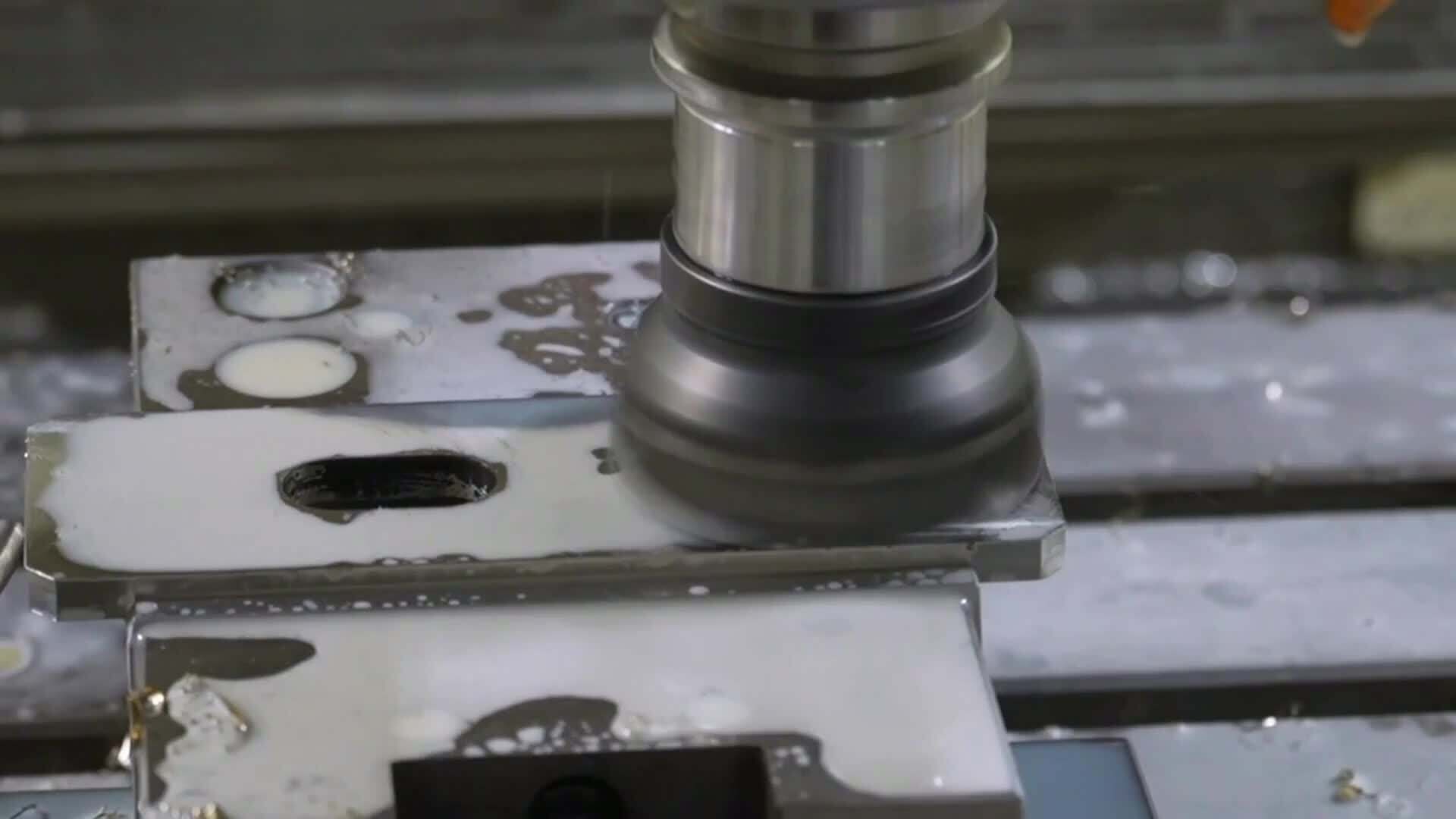

Ningbo Changfeng Mechanical Factory offers advanced CNC machining services tailored for rapid prototyping in engineering applications, leveraging over three decades of manufacturing expertise to deliver high-quality, custom solutions. Our services are designed to accelerate product development cycles, providing reliable prototyping that helps clients reduce time-to-market and minimize costs. With a strong global presence and extensive experience, we ensure precision and efficiency in every project, backed by a commitment to meeting diverse engineering needs. By choosing our CNC machining capabilities, businesses gain access to flexible, scalable prototyping that supports innovation across various industries.

The core of our service lies in advanced technology and adaptable processes, enabling us to handle complex geometries and diverse materials with high accuracy. Key features include:

- High-precision machining that achieves tight tolerances, ensuring prototypes meet exact specifications for functional testing.

- Rapid turnaround options that cater to urgent project timelines, helping clients iterate designs quickly.

- Full customization from design to production, allowing for bespoke solutions that fit unique engineering requirements.

- Scalable services that support both small-batch prototyping and larger production runs, making it ideal for product development stages.

Technical specifications highlight our capability to deliver consistent results. Below is a table summarizing key parameters:

| Parameter | Details |

|---|---|

| Material Types | Metals (e.g., aluminum, steel), Plastics, Composites |

| Tolerance Range | Customizable precision, typically ±0.005mm to ±0.1mm |

| Maximum Part Dimensions | Available upon request; scalable for various sizes |

| Surface Finish Options | As-machined, polished, anodized; customizable |

| Lead Time Flexibility | From 24 hours to several weeks; based on complexity |

Advantages of our CNC machining services include cost-efficiency through reduced waste and optimized material usage, as well as enhanced design flexibility that allows for iterative improvements. Clients benefit from our global logistics network, which facilitates smooth delivery to markets like North America, Europe, and Asia, backed by our established export operations. Additionally, our approach minimizes risks in prototyping by ensuring parts are functional and durable, directly supporting engineering validation and accelerating innovation cycles.

For businesses seeking reliable prototyping partners, our services offer a strategic edge in competitive engineering environments. Experience the difference with Ningbo Changfeng’s proven track record—contact us today for a consultation to discuss your specific needs and start your prototyping project. We provide dedicated support to help you achieve your goals efficiently and effectively.

Frequently Asked Questions (FAQ)

-

What materials can be machined for rapid prototyping?

We work with a range of materials including metals, plastics, and composites; specific options can be discussed based on your project requirements. -

How long does a typical rapid prototyping project take?

Lead times are customizable and depend on complexity; we offer rapid options starting from as little as 24 hours for simpler designs. -

Do you provide design assistance for CNC machining?

Yes, we offer engineering support to optimize designs for manufacturability, helping ensure prototypes meet functional needs efficiently. -

What industries benefit most from your services?

Our CNC prototyping serves diverse sectors such as automotive, aerospace, and consumer electronics, tailored to engineering applications. -

Is there a minimum order quantity for prototyping services?

No minimums are required; we accommodate single prototypes to larger batches, making it flexible for all stages of development. -

How do you ensure quality in CNC machined prototypes?

We employ rigorous inspection processes and precision equipment to maintain high standards, with quality control steps integrated throughout production. -

Can you handle complex or intricate part geometries?

Absolutely, our advanced CNC technology allows for intricate designs, and we can advise on feasibility during the consultation phase. -

What file formats are accepted for design submissions?

Common formats like STEP, IGES, and STL are accepted; we provide guidelines to ensure compatibility for smooth processing.

Send Inquiry to This Supplier

You May Also Like

-

Hot Selling CNC Milling Turning Customized Metal CNC Machining Services Non-standard Parts Turning Milling Composite ProcessingUS$ 10MOQ: 10 Units

-

High Grade Wholesale CNC Machining Precision Metal Parts Oem Odm Customized Aluminum Alloy Milling PartsUS$ 11MOQ: 10 Units

-

High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 Units

-

Advanced OEM CNC Machining Service for Stainless Steel Aluminum Brass Bronze & Copper Parts Including BroachingUS$ 13MOQ: 10 Units

-

High Precision CNC Lathe Turning Milling Machining Parts Custom Quality Aluminum Stainless Steel Brass Fabrication CNC ServicesUS$ 14MOQ: 10 Units

-

CNC Stainless Steel Cooling Plate 3D Printing Gear Ball Copper Screw Stamping Anodized Aluminum Ring Parts Cnc Machining ServiceUS$ 15MOQ: 10 Units

-

CNC Milling Parts Stainless Steel/Aluminum Alloy Compatible With CNC Machines for High-Accuracy Industrial FabricationUS$ 14MOQ: 10 Units

-

Precision CNC Milling Parts Aluminum/Steel/Brass in Various Sizes for Industrial Applications & Machinery FabricationUS$ 14MOQ: 10 Units

-

Versatile CNC Milling Parts Stainless Steel/Brass/Alloy Steel Suitable for Heavy-Duty Industrial & Manufacturing UseUS$ 14MOQ: 10 Units

-

CNC Milling Parts Aluminum/Carbon Steel With Quick Turnaround Times for Engineering Prototypes & Custom FabricationUS$ 14MOQ: 10 Units