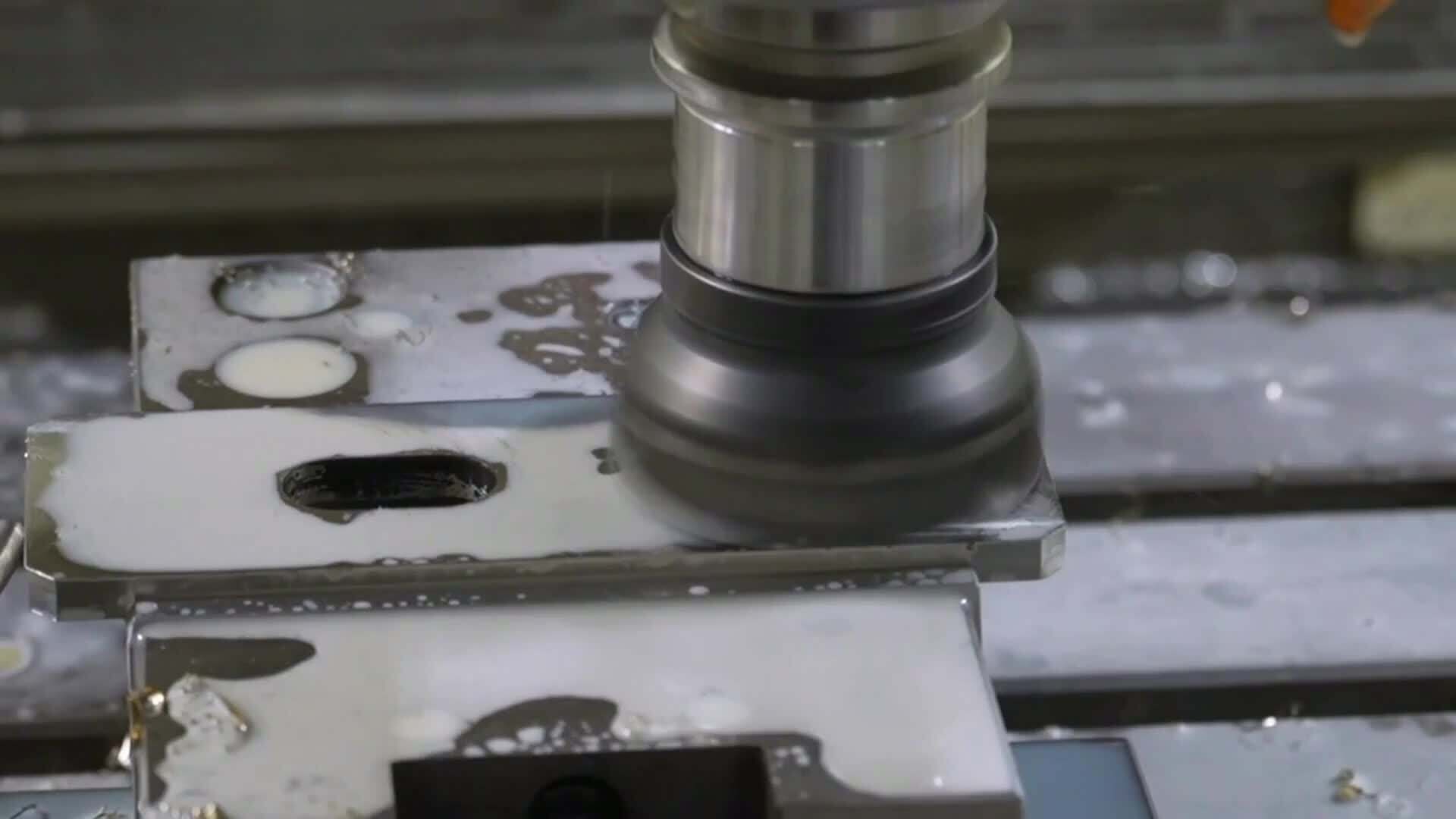

Efficient CNC Machining Services for Mass Production Batches and Small Quantity Orders

Ningbo Changfeng Mechanical Factory delivers precision CNC machining solutions for both large-scale production runs and limited prototype orders. With over 30 years of manufacturing expertise since our establishment in 1990, we've developed optimized processes that ensure consistent quality across all order volumes. Our integrated approach combines advanced technology with rigorous quality protocols to meet exacting industrial standards.

Operating from our 10,000+ sqm facility in Ningbo, China, we've served global clients across 15+ international markets including North America, Europe, and Asia-Pacific regions. The factory maintains an annual export value of $10-50 million USD, demonstrating our capacity to handle complex international supply chain requirements while maintaining competitive pricing structures for all order sizes.

Core Technical Advantages:

- Multi-axis machining capabilities for complex geometries

- Material flexibility including aluminum alloys, stainless steels, and engineering plastics

- Dedicated production lines for prototype validation before mass production

- Automated quality inspection systems with digital reporting

Production Specifications

| Parameter | Small Batch | Mass Production |

|---|---|---|

| Typical Lead Time | 5-10 working days | 10-15 working days |

| Minimum Order | 1 piece | 1,000+ units |

| Dimensional Accuracy | ±0.005mm | ±0.01mm |

| Surface Roughness | Ra 0.8μm | Ra 1.6μm |

Our flexible manufacturing system accommodates rapid changeovers between production runs, allowing efficient processing of mixed-volume orders. For prototype development, we provide design-for-manufacturability feedback to optimize part functionality and production efficiency. All projects include comprehensive documentation including material certifications and inspection reports.

Operational Benefits

- Dedicated project management with single-point contact

- Inventory management programs for high-volume clients

- Consolidated shipping options for international orders

- Secure data handling protocols for proprietary designs

We maintain strict process controls throughout production cycles, from material sourcing to final inspection. Our quality assurance team performs dimensional verification using CMM equipment and surface finish analysis with profilometers, ensuring every component meets specification requirements regardless of order size.

FAQ Section

Q: What file formats do you accept for part programming?

A: We accept all standard CAD formats including STEP, IGES, Parasolid, and native SolidWorks/CATIA files

Q: Can you handle post-machining treatments?

A: Yes, we provide in-house anodizing, plating, painting, and heat treatment services

Q: How do you ensure consistency in mass production?

A: Through statistical process control, fixture standardization, and automated inspection protocols

Q: What packaging options are available?

A: Custom packaging solutions including vacuum sealing, ESD protection, and custom foam inserts

Q: Do you offer design optimization services?

A: Our engineering team provides manufacturability analysis to reduce production costs

Leverage our three decades of machining expertise to streamline your manufacturing operations. Whether you require rapid prototyping for product development or high-volume production for established products, our integrated solutions reduce time-to-market while maintaining stringent quality standards. Contact our technical team today for project evaluation and competitive quotation.

Our global logistics network ensures reliable delivery to all major industrial markets, with consolidated shipping options available for multi-part assemblies. Partner with us to transform your design concepts into precision-engineered reality.

Send Inquiry to This Supplier

You May Also Like

-

CNC Stainless Steel Cooling Plate 3D Printing Gear Ball Copper Screw Stamping Anodized Aluminum Ring Parts Cnc Machining ServiceUS$ 15MOQ: 10 Units

-

CNC Milling Parts Stainless Steel/Aluminum Alloy Compatible With CNC Machines for High-Accuracy Industrial FabricationUS$ 14MOQ: 10 Units

-

Precision CNC Milling Parts Aluminum/Steel/Brass in Various Sizes for Industrial Applications & Machinery FabricationUS$ 14MOQ: 10 Units

-

Versatile CNC Milling Parts Stainless Steel/Brass/Alloy Steel Suitable for Heavy-Duty Industrial & Manufacturing UseUS$ 14MOQ: 10 Units

-

CNC Milling Parts Aluminum/Carbon Steel With Quick Turnaround Times for Engineering Prototypes & Custom FabricationUS$ 14MOQ: 10 Units

-

CNC Milling Parts Medical-Grade Stainless Steel/Aluminum Designed for Medical Device Production and InstrumentationUS$ 14MOQ: 10 Units

-

Custom CNC Milling Parts Stainless Steel Alloys Aluminum Brass for Automotive Industry Components Manufacturing and RepairsUS$ 14MOQ: 10 Units

-

Durable CNC Milling Parts Made From Aluminum and Stainless Steel Alloys for Heavy-Duty Industrial Equipment UseUS$ 14MOQ: 10 Units

-

High-Tolerance CNC Milling Parts Titanium/Stainless Steel With Smooth Finish for Aerospace Industry ApplicationsUS$ 14MOQ: 10 Units

-

Affordable CNC Milling Parts Aluminum Alloy/Carbon Steel for Machinery and Equipment Maintenance & RepairsUS$ 14MOQ: 10 Units