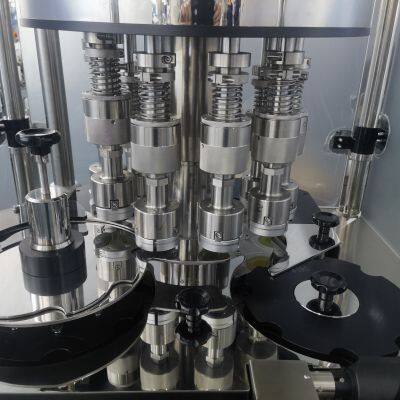

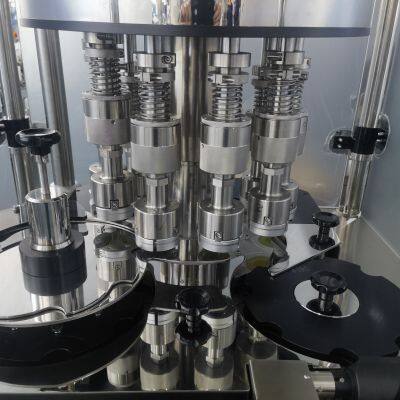

Automatic Rotary Screw Capping Machine BPX-300 With Centrifugal Cap Elevator

BPX-300 Rotary Capping Machine

Product Overview

The BPX-300 Rotary Capping Machine is an advanced automatic capping system independently developed by our company with reference to domestic and international similar products. This sophisticated equipment completes the entire capping process through an integrated workflow: bottles are conveyed via a belt system to an intake screw, transferred to an intake star wheel, and then guided along a contour plate to the capping star wheel where they are secured by anti-rotation belts. Caps are elevated to an orientation hopper via a centrifugal lift system, properly oriented caps descend through a chute to a distribution disc, and are then vacuum-lifted by capping heads for precise application. The capped bottles finally exit through a discharge star wheel onto the output conveyor. Incorporating cutting-edge technology with comprehensive protection and alarm systems for bottle jams, shortages, and overload conditions, this machine delivers reliable performance, scientific process flow, and compliance with national food hygiene standards.

Technical Specifications

| Parameter | Specification |

|---|---|

| Equipment Name | Rotary Capping Machine |

| Model | BPX-300 |

| Bottle Diameter/Height | Ø20–100mm / 45-200mm |

| Maximum Capacity | Up to 230 bottles/min (adjustable, container-dependent) |

| Cap Diameter | 20–60mm |

| Air Pressure | 0.6 MPa |

| Air Consumption | 0.5 L/min |

| Number of Capping Heads | 10 heads |

| Power | 3.5 kW |

| Voltage | 220V |

| Frequency | 50Hz |

| Dimensions (L×W×H) | 3000 × 2000 × 2200 mm |

| Weight | 2000 kg |

Key Features

Rotary Capping Structure: Compact design with stable performance characteristics

Centrifugal Cap Elevation System: Noiseless operation with automatic return of improperly oriented caps to storage hopper

Intelligent Control System: PLC programming with touchscreen interface for monitoring, alarm functions, and fault diagnostics

Torque Safety Protection: Automatic capping mechanism protection when torque limits are reached, preventing damage from overtightening

GMP-Compliant Construction: 304 stainless steel exterior frame with smooth, cleanable surfaces and no dead corners

Comprehensive Protection: Integrated alarm systems for bottle jams, shortages, cap deficiencies, and overload conditions

Automated Process Flow: Complete automation from bottle feeding to capped bottle discharge

High Production Efficiency: Optimized for continuous operation in demanding production environments

Easy Maintenance: Modular design with accessible components for simplified servicing

Seamless Integration: Compatible with various upstream and downstream packaging equipment

Applications

The BPX-300 is primarily designed for pharmaceutical, industrial, chemical, and food industries. This specialized equipment automatically applies screw caps to plastic bottles through its fully automated processes, significantly enhancing labor productivity while eliminating human contamination associated with manual capping. The machine functions effectively as a standalone unit or integrates seamlessly with unscramblers, counting machines, cotton inserters, sealers, labelers, and other packaging equipment to form complete production lines.

Operational Workflow

1. Bottle Handling System

Belt conveyor delivers bottles to intake screw mechanism

Intake star wheel transfers bottles along contour plate

Anti-rotation belts secure bottles during capping process

2. Cap Handling System

Centrifugal lift system elevates caps to orientation hopper

Properly oriented caps descend through chute to distribution disc

Improperly oriented caps automatically return to storage hopper

3. Capping System

10-head rotary capping mechanism with vacuum pickup

Precise cap placement and application

Torque-controlled tightening with safety protection

4. Discharge System

Capped bottles guided along contour plate to discharge star wheel

Final transfer to output conveyor for subsequent processing

System Advantages

High Precision: Accurate bottle positioning and cap application

Reliable Performance: Robust construction for continuous operation

Flexible Operation: Adjustable parameters for various bottle and cap specifications

Safety Assurance: Multiple protection systems prevent equipment damage and ensure operator safety

Hygienic Design: Compliant with pharmaceutical and food industry sanitation requirements

The BPX-300 represents a sophisticated capping solution that combines precision engineering with intelligent automation to deliver reliable, efficient performance for modern production facilities requiring high-volume, high-quality capping operations.

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Rotary Turntable for Round, Squre BottlesNegotiableMOQ: 1 Set

-

High-speed Automatic Bottle Unscrambler Applied in Pharmaceutial, Health Food IndustryNegotiableMOQ: 1 Set

-

High-speed BPL-300 Huge Automatic Bottle Unscrambler Automatic Bottle Unscrambler Applied in Pharmaceutial, Health Food IndustryNegotiableMOQ: 1 Set

-

BPL-Z Rotary Bottle Unscrambler Machine GMP Standard for Pharmaceutical Packaging LineNegotiableMOQ: 1 Set

-

BPL-200 Automatic Bottle Unscrambler Machine for Pharmaceutical Packaging LineNegotiableMOQ: 1 Set

-

High-Speed Automatic Bottle Sorting Machine 200 BPM With PLC Control SystemNegotiableMOQ: 1 Set

-

Automatic Stainless Steel Rotary Bottle Collecting Table PLC Controlled Bottle Unscrambler With Overload Protection and Touch ScreenNegotiableMOQ: 1 Set

-

BPL-Z Bottle Unscrambler for Pharmaceutical Chemical Food Industry GMP CertifiedNegotiableMOQ: 1 Set

-

High-Speed Automatic Unscrambler Machine BPL-300 With Horizontal OrientationNegotiableMOQ: 1 Set

-

Industrial Horizontal Bottle Unscrambler BPL-300 for Pharmaceutical & Cosmetic PackagingNegotiableMOQ: 1 Set