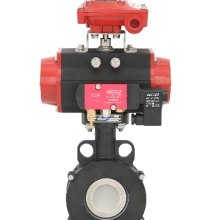

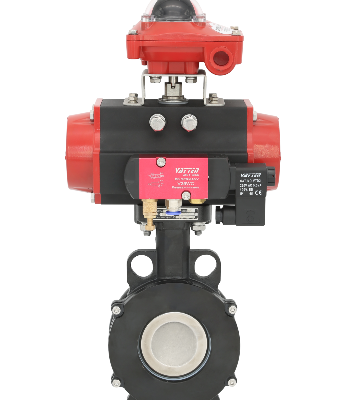

Pneumatic or Electric Actuator Compatible Full Fluorine-Lined Butterfly Valve With On/Off and Smart Regulating Options

The Pneumatic Double Eccentric High Performance Butterfly Valve (DN50-DN1200) is a versatile industrial control component that integrates precise flow regulation and reliable medium shut-off, designed to meet the diverse needs of complex industrial and municipal pipeline systems. Its unique double eccentric structure addresses common pain points of traditional butterfly valves—such as rapid seal wear and poor sealing under reverse flow—while the advanced RTFE or hard seal designs ensure long-term operational stability even in harsh conditions (e.g., high temperature, corrosive media). Whether used in metallurgy, chemical processing, food production, or municipal water treatment, this valve delivers consistent performance, reduces maintenance costs, and enhances overall pipeline safety.

What makes this valve stand out is its balance of functionality and adaptability. Unlike single-function valves that only regulate or shut off, it seamlessly switches between two modes, eliminating the need for multiple valve installations. Additionally, its integral cast body and optimized flow path design not only reduce weight and installation space but also minimize flow resistance, making it suitable for media with suspended particles or fibers that are prone to clogging conventional valves.

Core Features & Customer Benefits

Double Eccentric Structure for Extended Service Life: When closing, the valve disc expands outward to form an optimal peripheral seal; when opening, the disc quickly detaches from the seal ring. This design significantly reduces friction between the disc and seal, lowering operating torque and extending the seal’s lifespan—critical for industries requiring long-term, low-maintenance operations.

Two-Way Sealing for Leakage Prevention: Unlike standard one-way sealing butterfly valves, this model features two-way sealing. It maintains reliable sealing even if the medium flows in reverse or an "air hammer" occurs, avoiding costly medium waste or system contamination, especially in high-pressure gas or liquid applications (e.g., steam pipelines).

Flexible Seal Options for Diverse Conditions: Choose between RTFE soft seals (lip-tooth self-sealing structure) or hard seals (U-shaped elastic sealing structure) based on your needs. RTFE seals excel in low-to-medium temperature, non-corrosive scenarios, while hard seals are ideal for high-temperature (-60℃ ~ 450℃) or abrasive media. Both options meet strict seal classes (Class Ⅳ/Ⅴ or zero leakage for soft seals), ensuring compatibility with various industrial environments.

High Flow Efficiency & Anti-Clogging Design: The valve’s flow path diameter exceeds the requirements of GB12238, with almost no flow restriction. This design minimizes pressure loss, making its flow capacity second only to full-bore O-ball valves of the same size. It is particularly effective for turbid media, low-viscosity fluids with suspended particles, or fibrous materials, as it prevents accumulation and simplifies pipeline cleaning.

Lightweight & Compact for Easy Installation: The integral cast body reduces the valve’s weight and volume compared to traditional cast iron valves, saving transportation costs and installation space. Its compact design is especially beneficial for tight pipeline layouts in factories or municipal facilities where space is limited.

Key Technical Specifications

| Specification Category | Details | Typical Application Scenarios |

| Nominal Diameter | DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250, DN300, ..., DN1200 | Small-scale water treatment pipelines (DN50-DN100), large industrial steam pipelines (DN300-DN1200) |

| Nominal Pressure | 0.6MPa, 1.0MPa, 1.6MPa, 2.5MPa, 4.0MPa | Municipal tap water (0.6-1.0MPa), high-pressure chemical fluid transport (2.5-4.0MPa) |

| Applicable Temperature | -60℃ ~ 450℃ | Low-temperature refrigeration systems (-60℃ ~ 0℃), high-temperature steam pipelines (200℃ ~ 450℃) |

| Seal Type & Class | RTFE soft seal: Class Ⅳ (bubble class) or zero leakage; Hard seal: Class Ⅳ or Ⅴ | Food-grade liquid transport (RTFE soft seal, zero leakage), high-temperature gas control (hard seal, Class Ⅴ) |

| Flow Characteristic | Approximate equal percentage | Precision flow control in pharmaceutical, chemical, or power generation processes where stable flow adjustment is required |

Whether you need a valve for regulating steam flow in a power plant, controlling corrosive chemicals in a refinery, or managing sewage in a municipal treatment plant, the Pneumatic Double Eccentric High Performance Butterfly Valve can be tailored to your specific requirements. Its dual-function design reduces equipment redundancy, while its wide temperature and pressure range ensures compatibility with most industrial media. For customizations—such as specific seal materials, flange standards, or actuator configurations—please contact our team. We are committed to providing solutions that align with your operational goals and enhance the efficiency of your pipeline system.

FAQ (Frequently Asked Questions)

Q: Can this valve be used for food-grade media (e.g., edible oil, beverage processing)?

A: Yes, if you select the RTFE soft seal option. RTFE is non-toxic, odorless, and compliant with food safety requirements, while the valve’s zero-leakage performance and easy-to-clean flow path prevent cross-contamination. Please confirm your specific food safety standards when ordering, and we can provide additional documentation if needed.Q: What is the difference between RTFE soft seal and hard seal, and how do I choose?

A: RTFE soft seals offer better sealing performance (even zero leakage) and are suitable for low-to-medium temperatures (-60℃ ~ 200℃) and non-abrasive media (e.g., tap water, light oil). Hard seals (U-shaped elastic structure) withstand higher temperatures (-60℃ ~ 450℃) and abrasive media (e.g., slag-laden gas, slurry) but have slightly lower seal classes (Class Ⅳ/Ⅴ). Choose based on your media type, temperature range, and sealing requirements.Q: Is the valve compatible with media containing suspended particles or fibers?

A: Yes. The valve’s flow path has no significant constriction and exceeds GB12238 standards, which prevents particles or fibers from accumulating. This design makes it ideal for sewage treatment, pulp and paper processing, or other applications with turbid media, reducing the need for frequent cleaning or maintenance.Q: Can the valve operate reliably under reverse flow conditions?

A: Yes. It features a two-way sealing design, which differs from one-way sealing valves that leak under reverse flow. This makes it suitable for systems where media flow direction may change (e.g., bi-directional water supply pipelines) or where "air hammer" effects are common (e.g., compressed air systems).Q: What is the approximate service life of the seal, and how do I maintain it?

A: The RTFE soft seal typically lasts 1-3 years under normal conditions (room temperature, non-corrosive media), while the hard seal can last 3-5 years due to its wear resistance. Regular maintenance includes inspecting the seal for cracks or wear every 6-12 months and cleaning the flow path to remove debris. Replacement seals are available upon request, and we can provide maintenance guides for on-site teams.Q: Does the valve come with a pneumatic actuator, or is it sold separately?

A: The valve is designed as a pneumatic model and is typically supplied with a matching pneumatic actuator. However, actuator specifications (e.g., double-acting vs. single-acting, voltage for solenoid valves) can be customized based on your system. If you need a valve without an actuator (e.g., for retrofitting an existing actuator), please specify this when ordering.Q: Can the valve be installed outdoors, and will it withstand rain or humidity?

A: The standard valve body (usually cast steel or stainless steel) is corrosion-resistant, but outdoor installation may require additional protection. We recommend optional waterproofing for the actuator (e.g., IP65 or IP67 rating) and anti-rust coating for the valve body to prevent damage from rain, humidity, or outdoor debris. Please inform us of outdoor use requirements, and we can adjust the configuration accordingly.Q: Is the flow regulation precise enough for processes that require stable flow rates (e.g., chemical reactions)?

A: Yes. The valve’s approximate equal percentage flow characteristic ensures that small changes in valve opening correspond to proportional changes in flow rate, providing stable and precise regulation. This makes it suitable for processes in pharmaceuticals, fine chemicals, or power generation where consistent flow control is critical to product quality or process safety.

Send Inquiry to This Supplier

You May Also Like

-

Pneumatic Actuator-Ready Wafer Butterfly Valve Featuring Compact Design and Multiple Material Options for Gas and WaterNegotiableMOQ: 1 Set

-

Electric Wafer Butterfly Valve With Stainless Steel Disc & EPDM Seal for Industrial Fluid ControlNegotiableMOQ: 1 Set

-

Electric Actuator-Operated Wafer Butterfly Valve With Multi-Voltage OptionsNegotiableMOQ: 1 Set

-

Zero Leakage Full Fluorine-Lined Butterfly Valve Featuring Superior Corrosion Resistance and Long Service LifeNegotiableMOQ: 1 Set

-

Pneumatic or Electric Actuator Compatible Full Fluorine-Lined Butterfly Valve With On/Off and Smart Regulating OptionsNegotiableMOQ: 1 Set

-

Industrial Pneumatic Tank Bottom Valve for Food, Petroleum, Chemical, Paper, and Water Treatment ApplicationsNegotiableMOQ: 1 Set

-

Pneumatic Tank Bottom Valve Featuring Adjustable Upper Seal for Easy Maintenance and Leak Prevention in Process SystemsNegotiableMOQ: 1 Set

-

Fire-Safe and Anti-Static Pneumatic Tank Bottom Valve for Hazard Prevention in High-Risk Industrial EnvironmentsNegotiableMOQ: 1 Set

-

Pneumatic Control Valve With Valve Positioner for Frequent Adjustment Working Conditions Chinese FactoryNegotiableMOQ: 1 Piece

-

High Quality Pneumatic Control Valve for Chemical Pharmaceutical Industry Chinese Strong Factory With Spot StockNegotiableMOQ: 1 Piece