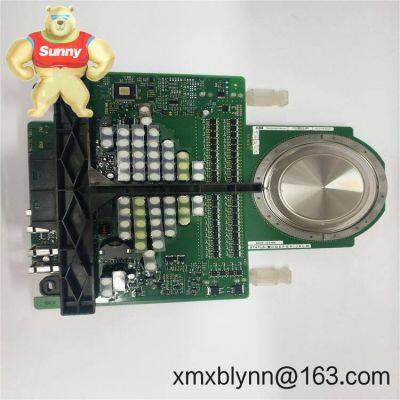

ABB 5SHX0860H0001 — Soft Starter Module for Low-Voltage Three‑Phase Motors

The ABB 5SHX0860H0001 is a low-voltage soft starter module typically used to limit inrush current and manage smooth start/stop sequences for industrial three‑phase motors. It appears to be sized for high-current motor installations (model code suggests an ~860 A class) and is commonly applied in pumps, fans, compressors and conveyor drives where reducing mechanical stress and electrical peak loads matters.

Core SummaryIn most cases this module is panel-mounted inside a control cabinet and integrates with plant PLCs via standard I/O and fieldbus options. One thing I appreciate is that it typically balances robust motor protection (overload, phase loss, locked rotor) with simple commissioning — ideal when you need fast deployment without complex drive tuning.

High current rating (~860 A class) — model code suggests suitability for medium-to-large motors; useful for pumps and compressors where large starting torque is required.

Soft start / soft stop control — reduces mechanical shock and extends coupling and gearbox life compared with DOL starts.

Motor protection functions — typically includes thermal overload protection, phase loss detection and locked-rotor monitoring.

Standard I/O — digital inputs for start/stop and interlocks, relay outputs for fault and run status; analog input for setpoint or feedback in many installations.

Fieldbus-capable — usually supports Modbus RTU over RS485 as standard and can accept optional Profibus/Profinet/EtherNet/IP modules in many ABB soft starter families.

Panel mounting — designed to be fitted into control cabinets, with spacing and ventilation recommendations to match LV switchgear practice.

| Brand / Model | ABB 5SHX0860H0001 |

| Power Requirements | Three‑phase low-voltage supply; typically 380–690 V AC (verify supply rating for your installation) |

| Rated Current | Model code indicates ~860 A class (use nameplate and supplier datasheet for exact continuous current rating) |

| Dimensions & Weight | Panel-mounted module; approximate footprint typically in the 300–450 mm height range and weighing commonly 10–20 kg depending on accessories — confirm with product datasheet. |

| Operating Temperature | Typically -20 °C to +60 °C (derating may be required above 40 °C) |

| Signal Inputs / Outputs | Digital inputs for start/stop and interlocks; relay outputs for run/fault; analog input (0–10 V or 4–20 mA) often available for external setpoints. |

| Communication Interfaces | Usually RS485 (Modbus RTU) standard; optional Profibus/Profinet/EtherNet/IP modules typical for system integration. |

| Installation Method | Panel/cabinet mounting with appropriate clearance for ventilation; electrical connections via stud or busbar depending on current class. |

From my experience this class of ABB soft starter is typically used in water & wastewater (large pump trains), HVAC chillers and cooling towers, industrial compressors, conveyor systems in mining and material handling, and any high-inertia motor loads where limiting torque spikes improves uptime.

Advantages & ValueReliability — simpler than a full variable-frequency drive and less likely to require complex tuning, so downtime is often reduced.

Compatibility — works with standard LV motors and integrates with PLCs using common fieldbus protocols in many cases.

Cost-efficiency — typically lower first-cost and maintenance expense compared with VFDs for pure starting/stopping and inrush control applications.

Serviceability — parts and spare modules are commonly available; commissioning is usually straightforward which saves engineering hours.

Basic site requirements are straightforward but worth emphasizing: install the unit inside an IP54+/IP55 cabinet rated for electrical gear, provide forced ventilation if ambient >40 °C, keep minimum clearances recommended in the datasheet, and route motor power cables separately from control wiring to reduce interference.

Electrical safety — always isolate incoming supply and follow lockout/tagout procedures before wiring or service.

Wiring — use correctly sized fuses or MCCB with appropriate short‑circuit protection and follow the manufacturer’s torque settings on power terminals.

Routine checks — inspect terminals for tightness annually, keep cooling passages clean, and verify fault logs after abnormal stops; calibrate any analog inputs during preventive maintenance cycles.

Firmware & configuration — firmware updates and configuration backups are normally done via a service port or fieldbus; from my experience, keep a copy of commissioning settings offsite for quicker replacement.

This product family typically carries CE marking and is RoHS compliant; many ABB low-voltage soft starters are also UL listed and built under ISO 9001 quality systems. Warranty terms usually run around 12 months from commissioning (or a specified period from shipment) — it appears prudent to confirm exact warranty duration and any extended-support options with your supplier at purchase.

Practical Notes & Customer FeedbackOne customer in municipal water treatment reported that swapping DOL starters for a similar ABB soft starter reduced peak demand during simultaneous pump starts and noticeably lengthened coupling life — results that were apparent within months. You might notice that commissioning is faster than expected, though advanced integration (Profibus/Profinet) requires attention to fieldbus addressing and grounding.

If you need exact rated current, dimensional drawings, or ordering codes for options (control card, bypass contactor, fieldbus module), I recommend requesting the manufacturer's datasheet or specifying the application (motor kW, supply voltage, start method) so the correct variant and accessories can be confirmed.

Send Inquiry to This Supplier

You May Also Like

-

ABB 5SHX19L6010 — Compact Low‑Voltage Motor Soft Starter for Industrial DrivesNegotiableMOQ: 1 Combo

-

ABB 5SHX2645L0001 — IGCT Power Module for Medium‑Voltage ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHX3545L0016 / 3BHB020720R0002 — High‑Power IGCT Module for Industrial ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHY0660L0001 IGCT — High‑power IGCT Module for Medium/High‑Power ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHY3545L0001 — Asymmetric Thyristor IGCT for High-Power ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHY3545L0004 — Auxiliary Contact Module for Low-Voltage Motor ProtectionNegotiableMOQ: 1 Combo

-

ABB 5SHY3545L0006 — Auxiliary Contact Block for Motor Control and ProtectionNegotiableMOQ: 1 Combo

-

ABB 5SHY40L4511 IGCT Module — High‑power Turn‑off Thyristor for Industrial ConvertersNegotiableMOQ: 1 Combo

-

ABB 5SHY42L6500 — Asymmetric Thyristor IGCT for High-Power ConversionNegotiableMOQ: 1 Combo

-

ABB 5SHY50L5500 — Low-voltage Motor Drive for Precise Speed & Torque ControlNegotiableMOQ: 1 Combo