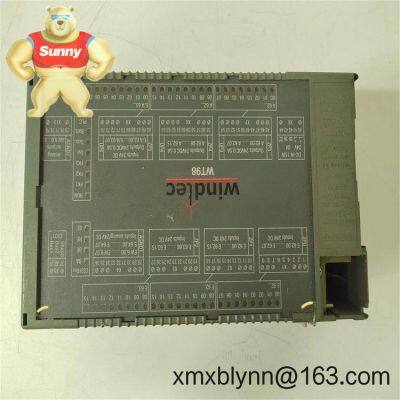

ABB 07KT98 (GJR5253100R4278) – High‑reliability Rack Module for Advant/Master DCS Communication and Control

The ABB 07KT98, order code GJR5253100R4278, is a plug‑in module designed for legacy ABB Advant/Master-class DCS racks, typically used as a communication and controller interface between the central processor and plant I/O or subsystem networks. From my experience, plants keep this module in service because it’s stable, predictable, and integrates cleanly with existing backplanes without forcing a wholesale migration.

You might notice that this unit is often specified when extending life on installed Advant/Master systems—particularly where serial links and system bus connections need to remain intact during phased upgrades.

Rack plug‑in module for ABB Advant/Master systems – slides into the standard 07KT-series backplane with keyed connectors for quick service.

System bus and serial integration – typically supports the system backplane bus plus one or more serial channels (e.g., RS‑232/RS‑485) for field devices or gateways, depending on firmware/revision.

Deterministic operation – tuned for process automation use where predictable scan and update timing matters.

Backward‑compatible behavior – designed to work within existing cabinets and power schemes, avoiding cabinet redesign in most cases.

Serviceable design – front access for LED status and field connectors makes troubleshooting faster during shift work.

Proven in long‑running plants – commonly found in power, pulp & paper, and chemicals where continuous operation is the norm.

Application Fields

Application FieldsPlants usually deploy 07KT98 modules where stable, legacy DCS communication is non‑negotiable—such as base‑load power stations, pulp & paper lines, petrochemical units, cement kilns, and metals processing. It seems to be especially useful during staged modernization, when you need to keep serial instruments, older gateways, and rack I/O talking to the central controller with minimal disruption.

Power generation: turbine balance‑of‑plant links and auxiliary systems

Pulp & paper: stock prep, digesters, and paper machine drives integration

Chemicals & refining: unit operations with long‑lived analyzers and serial packages

Cement & minerals: kiln, mill, and cooler control interlocks

Metals: rolling and continuous casting support systems

Reliability you can keep running – these modules are known to run for years in controlled cabinets, cutting downtime risk.

Lifecycle extension without re‑wiring – leverages the existing backplane, so you typically avoid new cabinets, ducting, or I/O marshaling changes.

Compatibility with mixed vintages – helps bridge older serial devices and DCS infrastructure during phased migrations.

Cost control – compared with wholesale DCS replacement, a single module swap keeps CAPEX modest and turnaround fast.

Technical support ecosystem – well understood by field technicians; spares, repair, and firmware support are widely available.

A maintenance supervisor recently told me their spare 07KT98 “paid for itself the first time we used it”—they were back online inside a single shift after a comms fault, with no logic changes.

Installation & MaintenanceCabinet & environment – mount in a clean, dry control cabinet; maintain adequate ventilation and keep ambient within typical 0…55 °C.

Power & grounding – ensure stable backplane supply and proper cabinet grounding to minimize communication noise on serial lines.

Wiring – follow ABB pinout and shield‑drain practices; segregate low‑level signal cabling from power runs to reduce EMI.

ESD handling – use wrist straps and antistatic packaging when inserting or removing the module.

Firmware & configuration – match firmware revision to the controller/engineering tools in use; keep a tested backup of the configuration.

Routine care – visually inspect connectors and LEDs during scheduled stops; clean dust from card edges; verify serial link health and update logs.

Compliance – ABB modules in this class are typically CE marked; many production batches also carry UL recognition and RoHS conformity.

Quality system – manufactured under ABB’s ISO‑certified quality processes.

Warranty – manufacturer warranty is commonly 12 months; confirm coverage against the specific serial/revision of your unit.

Send Inquiry to This Supplier

You May Also Like

-

ABB 3BSE017235R1 – S800 I/O/AC 800M Accessory for Reliable I/O ExpansionNegotiableMOQ: 1 Combo

-

ABB 83SR04C-E (GJR2390200R1411) – Relay Output Module for Procontrol P14 SystemsNegotiableMOQ: 1 Combo

-

ABB HIEE305098R0001 – Plug‑in DCS Module for Legacy System Expansion and Reliable SparesNegotiableMOQ: 1 Combo

-

ABB 5SHY35L4522 IGCT Gate Unit – Trusted Drive Control for High‑power ConvertersNegotiableMOQ: 1 Combo

-

ABB 07AI91 (GJR5251600R4202) – Analog Input Module for AC31/CS31 Process ControlNegotiableMOQ: 1 Combo

-

ABB 07BR61R1 (GJV3074376R1) – MasterBus 300 Repeater for Segment Isolation and Distance ExtensionNegotiableMOQ: 1 Combo

-

ABB 07DC91 (GJR5251400R0202) – Digital Control/communication Module for Legacy Procontrol/Advant 07-series SystemsNegotiableMOQ: 1 Combo

-

ABB 07EA90-SI (GJR5251200R0101) – System Interface Module for Advant Master S100 I/ONegotiableMOQ: 1 Combo

-

ABB 07KT94 (GJR5252100R3261) – Communication/Processor Module for Advant Controller 31 (AC31) SystemsNegotiableMOQ: 1 Combo

-

ABB 086318-002 / 086318-501 – Legacy I/O Termination Assembly for ABB Bailey INFI 90 / NET 90 CabinetsNegotiableMOQ: 1 Combo