1.4435 Stainless Steel Coil for Petrochemical Industry, 316H/S32205, With Heat and Corrosion Resistance

1.4435 Stainless Steel Coil for Petrochemical Industry: 316H/S32205 - A Superior Solution

Introduction

In the highly demanding petrochemical industry, the choice of materials is crucial for ensuring the safety, efficiency, and longevity of equipment. Our 1.4435 stainless steel coil, available in 316H/S32205 grades, stands out as an exceptional option. This product is designed to meet the stringent requirements of the petrochemical sector, offering outstanding heat and corrosion resistance.

Product Overview

- Surface Treatment: The coil undergoes a polished surface treatment. This not only gives it an aesthetically pleasing appearance but also provides several functional benefits. The polished surface reduces friction, making it easier to clean and maintain. It also enhances the corrosion - resistance of the steel by creating a smooth barrier that prevents the accumulation of contaminants.

- Technique: It is produced using the hot - rolled technique. Hot rolling is a well - established and reliable manufacturing process. It allows for the production of large - scale coils with consistent quality. During hot rolling, the steel is heated above its recrystallization temperature, which improves its ductility and formability. This means that the coil can be easily shaped and fabricated into various components required in the petrochemical industry.

- Standard: Our 1.4435 stainless steel coil adheres to the ASTM standard. ASTM standards are widely recognized and respected in the international market. By meeting these standards, our product ensures high quality, reliability, and compatibility with other components in petrochemical facilities.

Heat and Corrosion Resistance

- Heat Resistance: The 316H/S32205 grades of our stainless steel coil offer excellent heat resistance. In the petrochemical industry, many processes involve high temperatures. For example, in refineries, cracking units operate at extremely high temperatures. Our coil can withstand these high - temperature environments without significant degradation. It retains its mechanical properties, such as strength and toughness, even at elevated temperatures. This ensures the long - term performance of equipment made from this coil, reducing the need for frequent replacements.

- Corrosion Resistance: Corrosion is one of the biggest challenges in the petrochemical industry. The presence of harsh chemicals, such as acids, alkalis, and salts, can cause rapid deterioration of equipment. Our 1.4435 stainless steel coil has exceptional corrosion resistance. The alloy composition of 316H/S32205 contains elements like chromium, nickel, and molybdenum, which form a passive oxide layer on the surface of the steel. This layer acts as a protective barrier, preventing the penetration of corrosive substances and extending the service life of the coil.

Applications in the Petrochemical Industry

- Pipelines: Our stainless steel coil is ideal for manufacturing pipelines in petrochemical plants. Pipelines are used to transport various fluids, including crude oil, refined products, and chemicals. The heat and corrosion resistance of the coil ensure that the pipelines can operate safely and efficiently over long periods. They can withstand the high - pressure and high - temperature conditions inside the pipelines, as well as the corrosive nature of the transported fluids.

- Storage Tanks: Storage tanks in the petrochemical industry need to be able to hold large volumes of chemicals and petroleum products. Our coil can be used to fabricate these storage tanks. Its corrosion resistance protects the tank from internal and external corrosion, preventing leaks and ensuring the integrity of the stored substances.

- Reaction Vessels: In chemical processes within petrochemical plants, reaction vessels are used to carry out various chemical reactions. These vessels are exposed to high temperatures, pressures, and corrosive chemicals. The heat and corrosion resistance of our stainless steel coil make it a suitable material for constructing reaction vessels, ensuring the smooth operation of chemical reactions.

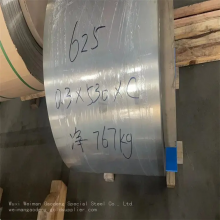

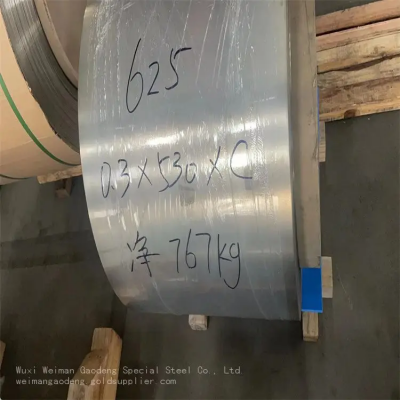

Company - Backed Quality

- Manufacturer Expertise: We, Wuxi Weiman Gaodeng Special Steel Co., Ltd., are a well - established manufacturer with a history dating back to 2017. Our company has grown from a research - and - development - focused startup to a global special steel solution provider. We have a team of experts, including a CEO with over 20 years of experience in the special steel industry and a chief metallurgist with a PhD from Tsinghua University.

- Quality Assurance: Our company is committed to providing high - precision special steel solutions. We offer customized materials and value - added services for global industries, ensuring compliance with international standards such as ASTM, EN, JIS, and API. Our products are subject to advanced non - destructive testing (NDT) services, including ultrasonic testing (UT) and magnetic particle testing (MT). These tests help detect internal and surface defects, ensuring the quality and reliability of our 1.4435 stainless steel coil.

- Logistics and Delivery: With strategically located warehouses in Wuxi, we can ensure 48 - hour delivery to major Chinese ports. This rapid logistics service allows our international customers in North America, South America, Europe, Asia, Africa, and Oceania to receive their orders in a timely manner, minimizing downtime in their petrochemical operations.

In conclusion, our 1.4435 stainless steel coil in 316H/S32205 grades is a top - notch product for the petrochemical industry. Its heat and corrosion resistance, combined with our company's expertise and quality assurance, make it a reliable choice for various applications in petrochemical facilities around the world.

Send Inquiry to This Supplier

You May Also Like

-

17-7PH Stainless Steel Coil for Pressure Vessel Manufacturing, S31803/304H, With High ToughnessNegotiableMOQ: 1 Ton

-

316L Stainless Steel Coil for High-Pressure Equipment, 1.4529/347H, Offering Durability and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

17-4PH Stainless Steel Coil for Heavy Industry Machinery, F44/2205, With Superior StrengthNegotiableMOQ: 1 Ton

-

1.4460 Stainless Steel Coil for Marine Equipment, SUS631/F52, With Wear and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

2507 Stainless Steel Coil for Oil & Gas Pipelines, 316LMOD/316Ti, With Corrosion and Fatigue ResistanceNegotiableMOQ: 1 Ton

-

F51 Stainless Steel Coil for Chemical Processing, S32950/316Ti, With Exceptional Mechanical PropertiesNegotiableMOQ: 1 Ton

-

316L Stainless Steel Coil for Electrical Equipment, F53/1.4547, Offering Heat Resistance and DurabilityNegotiableMOQ: 1 Ton

-

2507 Stainless Steel Coil for Structural Steel Construction, 31703/F44, With High StrengthNegotiableMOQ: 1 Ton

-

347H Stainless Steel Coil for Thermal Energy Equipment, S31803/316H, With High-Temperature ResistanceNegotiableMOQ: 1 Ton

-

ASTM AISI 201 304 316L 310S 409L 420 430 431 434 439 304 316 No. 1/2b/Ba/No. 4/Brushed/8K Mirror Stainless Steel Coil PriceNegotiableMOQ: 1 Ton