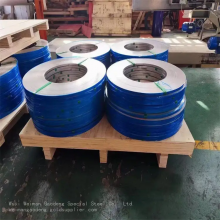

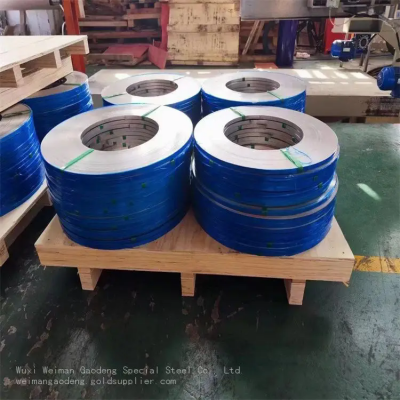

SUS329J1 Stainless Steel Coil for Aerospace Components, S34778/F51, Offering Strength and Corrosion Resistance

Product Overview

Our SUS329J1 Stainless Steel Coil, with the grade S34778/F51, is a high - performance product specifically designed for aerospace components. In the demanding aerospace industry, where safety and reliability are of utmost importance, this stainless steel coil stands out as a top - choice material. It combines excellent strength and remarkable corrosion resistance, making it suitable for a wide range of aerospace applications.

Surface Treatment and Technique

The surface of our SUS329J1 Stainless Steel Coil is polished. This polished finish not only gives the coil an aesthetically pleasing appearance but also provides several practical benefits. A polished surface reduces the friction coefficient, which is crucial in aerospace components where smooth movement and reduced wear are essential. It also helps in preventing the accumulation of dirt, debris, and contaminants, which could potentially compromise the performance of the components.

The coil is manufactured using the hot - rolled technique. Hot rolling is a well - established and reliable manufacturing process. It allows for the production of steel with uniform grain structure and enhanced mechanical properties. During hot rolling, the steel is heated above its recrystallization temperature, which enables it to be shaped easily while also improving its strength and ductility. This results in a stainless steel coil that can withstand the high - stress environments typically found in aerospace applications.

Standard Compliance

Our SUS329J1 Stainless Steel Coil adheres to the ASTM standard. ASTM standards are widely recognized and respected in the global market. By meeting these standards, our product ensures consistent quality and performance. Aerospace manufacturers can have full confidence in using our coil, knowing that it has been rigorously tested and meets the strict requirements set by ASTM. This compliance also facilitates international trade, as it is a well - understood and accepted benchmark in the industry.

Strength and Corrosion Resistance

One of the key features of our SUS329J1 Stainless Steel Coil is its exceptional strength. In aerospace applications, components are often subjected to extreme forces, such as high - speed airflow, vibrations, and mechanical stresses. The high strength of our coil allows it to maintain its integrity under these harsh conditions, ensuring the safety and reliability of the aerospace systems. Whether it is used in structural components or in parts that need to withstand high - pressure environments, our stainless steel coil delivers outstanding performance.

Corrosion resistance is another critical aspect, especially in the aerospace industry where components are exposed to various corrosive agents, such as moisture, saltwater, and chemicals. Our SUS329J1 Stainless Steel Coil has excellent corrosion - resistant properties, which protect it from rust and degradation over time. This not only extends the service life of the components but also reduces the need for frequent maintenance and replacement, resulting in cost savings for aerospace manufacturers.

Application in Aerospace Components

Our SUS329J1 Stainless Steel Coil can be used in a variety of aerospace components. It is suitable for manufacturing structural parts, such as frames and supports, where its high strength is essential for maintaining the integrity of the aircraft. It can also be used in engine components, where it needs to withstand high temperatures and corrosive exhaust gases. Additionally, it is ideal for use in hydraulic systems, as its corrosion resistance ensures the smooth operation of the system and prevents contamination of the hydraulic fluid.

Company - Backed Assurance

We are Wuxi Weiman Gaodeng Special Steel Co., Ltd., a manufacturer established in 2017. With an annual export share ranging from US$5 Million - US$10 Million, we have a proven track record in the international market. Our company is specialized in high - precision special steel solutions. We offer customized materials and value - added services for global industries, ensuring compliance with international standards such as ASTM, EN, JIS, and API.

Our expert team, led by Mr. Sang Le (CEO) with over 20 years of experience in special steel and Dr. Li Wei (Chief Metallurgist) with a PhD in Materials Science from Tsinghua University, is committed to driving quality through technical excellence. We also collaborate with global partners like SGS and BV for third - party audits, ensuring that our products meet the highest standards.

We have advanced processing and testing capabilities. Our factory - made fabrication includes welded elbows and flanges per ASME B16.9, with radiographic testing (RT) and liquid penetrant testing (PT). We also offer custom - cutting services for plates (max thickness 120mm) and pipes (OD 20 - 1200mm). Our advanced NDT services, such as Ultrasonic Testing (UT) to EN 10228 - 3 and Magnetic Particle Testing (MT) for surface cracks, certified by SGS and BV, ensure the quality of our products.

When you choose our SUS329J1 Stainless Steel Coil for your aerospace components, you are not only getting a high - quality product but also the support and assurance of a reliable and experienced manufacturer.

Send Inquiry to This Supplier

You May Also Like

-

1.4460 Stainless Steel Coil for Marine Equipment, SUS631/F52, With Wear and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

2507 Stainless Steel Coil for Oil & Gas Pipelines, 316LMOD/316Ti, With Corrosion and Fatigue ResistanceNegotiableMOQ: 1 Ton

-

F51 Stainless Steel Coil for Chemical Processing, S32950/316Ti, With Exceptional Mechanical PropertiesNegotiableMOQ: 1 Ton

-

316L Stainless Steel Coil for Electrical Equipment, F53/1.4547, Offering Heat Resistance and DurabilityNegotiableMOQ: 1 Ton

-

2507 Stainless Steel Coil for Structural Steel Construction, 31703/F44, With High StrengthNegotiableMOQ: 1 Ton

-

347H Stainless Steel Coil for Thermal Energy Equipment, S31803/316H, With High-Temperature ResistanceNegotiableMOQ: 1 Ton

-

ASTM AISI 201 304 316L 310S 409L 420 430 431 434 439 304 316 No. 1/2b/Ba/No. 4/Brushed/8K Mirror Stainless Steel Coil PriceNegotiableMOQ: 1 Ton

-

Stainless Steel Coil for Chemical Processing, 17-4PH/SUS630/2205, With High Corrosion ResistanceNegotiableMOQ: 1 Ton

-

17-7PH Stainless Steel Coil for Aerospace Applications, F51/316Ti, Offering Exceptional StrengthNegotiableMOQ: 1 Ton

-

SUS631 Stainless Steel Coil for Chemical Industry, F52/2507, With Superior Corrosion ResistanceNegotiableMOQ: 1 Ton