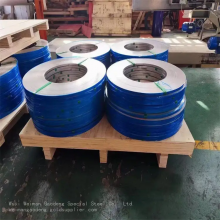

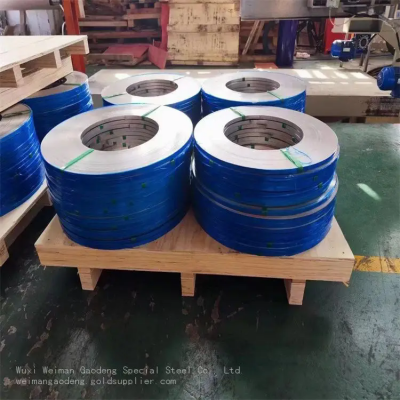

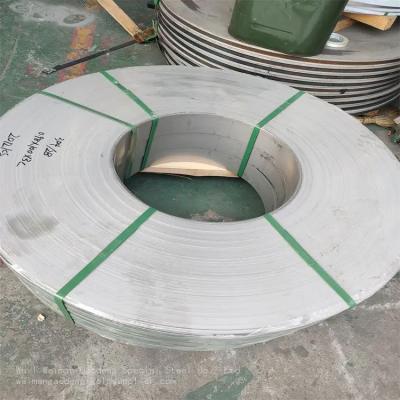

1.4460 Stainless Steel Coil for Marine Equipment, SUS631/F52, With Wear and Corrosion Resistance

Product Overview

Our 1.4460 Stainless Steel Coil, also known as SUS631/F52, is a high - performance material specifically designed for marine equipment. With its exceptional wear and corrosion resistance, it is an ideal choice for various applications in the harsh marine environment.

Surface Treatment

The surface of this stainless steel coil is polished. This polished finish not only gives the coil an aesthetically pleasing appearance but also provides several functional benefits. A polished surface reduces the friction coefficient, which can minimize wear when the coil is in contact with other components. Moreover, it helps to prevent the accumulation of dirt, debris, and marine organisms on the surface, further enhancing its corrosion resistance. The smooth surface also makes it easier to clean and maintain, which is crucial for long - term use in marine equipment.

Manufacturing Technique

The coil is produced using the hot - rolled technique. Hot rolling is a well - established manufacturing process that offers several advantages. During hot rolling, the steel is heated above its recrystallization temperature and then passed through rollers to achieve the desired thickness and shape. This process results in a more uniform grain structure within the steel, which improves its mechanical properties. The hot - rolled 1.4460 stainless steel coil has better ductility and toughness compared to cold - rolled products, making it more suitable for applications where the material may be subjected to bending, forming, or impact forces.

Standard Compliance

Our 1.4460 Stainless Steel Coil adheres to the ASTM standard. ASTM (American Society for Testing and Materials) standards are widely recognized and accepted in the international market. By meeting the ASTM standards, our product ensures high - quality and reliability. The ASTM standards specify strict requirements for the chemical composition, mechanical properties, and dimensional accuracy of the stainless steel. This means that our coil can be used with confidence in various marine equipment applications, knowing that it meets the industry - recognized quality benchmarks.

Wear and Corrosion Resistance

One of the most significant features of this stainless steel coil is its outstanding wear and corrosion resistance. In the marine environment, equipment is constantly exposed to saltwater, which is highly corrosive. The 1.4460 grade stainless steel contains specific alloying elements that form a passive oxide layer on the surface. This oxide layer acts as a barrier, preventing the underlying steel from reacting with the corrosive agents in the saltwater.

In addition to corrosion resistance, the coil also has excellent wear resistance. Marine equipment often experiences friction and abrasion due to the movement of parts and the impact of sand, rocks, and other debris in the water. The hard and durable nature of the 1.4460 stainless steel allows it to withstand these wear - inducing factors, ensuring a longer service life for the equipment.

Applications in Marine Equipment

This stainless steel coil has a wide range of applications in marine equipment. It can be used in the construction of ship hulls, where its corrosion resistance helps to protect the vessel from the damaging effects of saltwater. It is also suitable for use in marine pumps, valves, and pipes, as these components need to resist both corrosion and wear. In addition, it can be employed in offshore platforms, where it is exposed to harsh weather conditions and salt - laden air. The coil can be fabricated into various shapes and sizes to meet the specific requirements of different marine equipment applications.

Company - Backed Quality

Our company, Wuxi Weiman Gaodeng Special Steel Co., Ltd., is a professional manufacturer with a rich history and a strong technical team. Since its establishment in 2017, we have been committed to providing high - precision special steel solutions. We have a large export share, ranging from US$5 Million - US$10 Million, and our products are sold to major markets around the world, including North America, South America, Europe, Asia, Africa, and Oceania.

Our company has advanced processing and testing capabilities. We can perform factory - made fabrication, such as producing welded elbows and flanges per ASME B16.9, and we conduct radiographic testing (RT) and liquid penetrant testing (PT) to ensure the quality of our products. We also offer custom - cutting services for plates and pipes, with a maximum plate thickness of 120mm and pipe outer diameters ranging from 20 - 1200mm. Our advanced NDT services, including Ultrasonic Testing (UT) to EN 10228 - 3 and Magnetic Particle Testing (MT) for surface cracks, certified by SGS and BV, guarantee that our 1.4460 Stainless Steel Coil meets the highest quality standards.

In conclusion, our 1.4460 Stainless Steel Coil, with its polished surface, hot - rolled technique, ASTM compliance, and excellent wear and corrosion resistance, is the perfect choice for marine equipment applications. Trust in our product and our company's expertise to provide you with a reliable and long - lasting solution for your marine equipment needs.

Send Inquiry to This Supplier

You May Also Like

-

ASTM AISI 201 304 316L 310S 409L 420 430 431 434 439 304 316 No. 1/2b/Ba/No. 4/Brushed/8K Mirror Stainless Steel Coil PriceNegotiableMOQ: 1 Ton

-

Stainless Steel Coil for Chemical Processing, 17-4PH/SUS630/2205, With High Corrosion ResistanceNegotiableMOQ: 1 Ton

-

17-7PH Stainless Steel Coil for Aerospace Applications, F51/316Ti, Offering Exceptional StrengthNegotiableMOQ: 1 Ton

-

SUS631 Stainless Steel Coil for Chemical Industry, F52/2507, With Superior Corrosion ResistanceNegotiableMOQ: 1 Ton

-

304H Stainless Steel Coil for Food Processing, 1.4529/316L, Offering Thermal StabilityNegotiableMOQ: 1 Ton

-

17-4PH Stainless Steel Coil for High-Performance Heat Exchangers, F55/S32760, With Exceptional DurabilityNegotiableMOQ: 1 Ton

-

F53 Stainless Steel Coil for High-Temperature Applications, S31254/316H, Offering Superior ResistanceNegotiableMOQ: 1 Ton

-

316Ti Stainless Steel Coil for Oil & Gas Industry, 2507/316H, With High Durability and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

S32750 Stainless Steel Coil for Food & Beverage Manufacturing, 317L/304H, With Precision and DurabilityNegotiableMOQ: 1 Ton

-

17-4PH Stainless Steel Coil for Medical Devices, F44/S20910, With Heat and Corrosion ResistanceNegotiableMOQ: 1 Ton