F53 Stainless Steel Coil for Chemical Transport, 1.4529/2507, With Exceptional Corrosion Resistance

Introduction

In the realm of chemical transport, the choice of materials is of utmost importance. Our F53 Stainless Steel Coil, also known as 1.4529/2507, stands out as an exceptional solution. With its remarkable corrosion resistance, it is specifically designed to meet the rigorous demands of chemical transportation, ensuring the safety and integrity of the chemicals being transported.

Product Overview

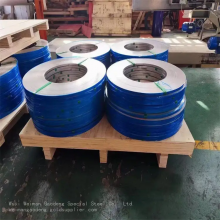

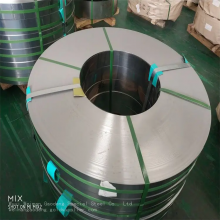

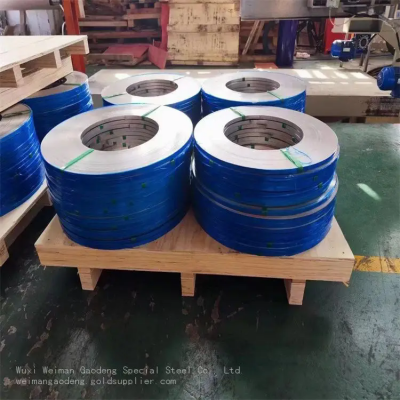

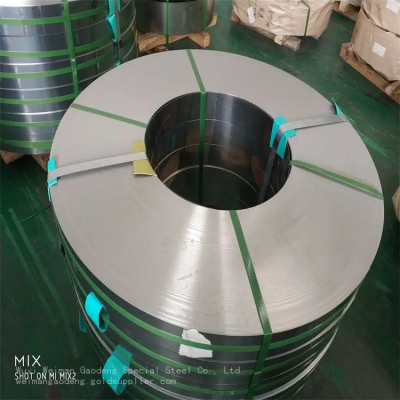

- Type: Our product is a stainless - steel coil, which offers flexibility in application. Coils can be easily cut, formed, and fabricated into various shapes according to the specific requirements of chemical transport equipment, such as storage tanks, pipelines, and containers.

- Surface Treatment: The coil undergoes a polished surface treatment. This not only gives it an aesthetically pleasing appearance but also has practical benefits. A polished surface is smoother, which reduces the adhesion of chemicals, making it easier to clean and maintain. It also helps in preventing the accumulation of contaminants that could potentially cause corrosion over time.

- Technique: It is produced using the hot - rolled technique. Hot rolling enhances the mechanical properties of the stainless steel. The high - temperature process refines the grain structure of the metal, resulting in improved strength, toughness, and ductility. This makes the coil more resistant to deformation during the manufacturing of chemical transport equipment and also better able to withstand the stresses encountered during transportation.

- Standard: Our F53 Stainless Steel Coil adheres to the ASTM standard. ASTM standards are widely recognized and respected in the international market. By meeting these standards, our product ensures high - quality and reliability, giving customers confidence in its performance and compliance with industry norms.

Exceptional Corrosion Resistance

- Chemical Resistance: F53 stainless steel is highly resistant to a wide range of chemicals commonly transported in the industry. It can withstand the corrosive effects of acids, alkalis, and salts. For example, it shows excellent resistance to sulfuric acid, hydrochloric acid, and sodium hydroxide solutions. This resistance is crucial as it prevents the degradation of the coil, ensuring that the chemical being transported remains uncontaminated and the equipment remains in good working condition.

- Pitting and Crevice Corrosion Resistance: In chemical transport, pitting and crevice corrosion can be major issues. Pitting corrosion occurs when small holes form on the surface of the metal, while crevice corrosion happens in narrow spaces or gaps. Our F53 Stainless Steel Coil has excellent resistance to both pitting and crevice corrosion. The alloy composition of F53, which includes elements such as chromium, molybdenum, and nitrogen, creates a passive film on the surface of the steel. This film acts as a barrier, protecting the metal from the corrosive environment and preventing the initiation and propagation of pitting and crevice corrosion.

Manufacturing and Quality Assurance

- Advanced Manufacturing Process: Our company, with its rich experience and advanced manufacturing facilities, produces the F53 Stainless Steel Coil with high precision. We use state - of - the - art equipment and strict quality control measures at every stage of the production process. From raw material selection to the final inspection, we ensure that each coil meets the highest quality standards.

- Testing and Certification: The coil undergoes a series of comprehensive tests to guarantee its quality. We perform chemical composition analysis to ensure that the alloy elements are within the specified range. Mechanical property tests, such as tensile strength and hardness tests, are also carried out. In addition, we use advanced non - destructive testing (NDT) methods, including ultrasonic testing (UT) and magnetic particle testing (MT). UT can detect internal defects as small as 0.5mm, while MT can identify surface cracks. Our testing facilities are certified by SGS and BV, which are well - known international certification bodies, further validating the quality of our product.

Application in Chemical Transport

- Storage Tanks: Our F53 Stainless Steel Coil is an ideal material for manufacturing chemical storage tanks. The corrosion resistance of the coil ensures that the tank can safely store various chemicals for long periods without the risk of leakage or contamination. The strength and durability of the coil also allow the tank to withstand the pressure and weight of the stored chemicals.

- Pipelines: In chemical transport pipelines, the F53 coil can be fabricated into pipes. The smooth interior surface of the pipes, thanks to the polished treatment, reduces the flow resistance of the chemicals, improving the efficiency of transportation. The high corrosion resistance prevents the formation of rust and scale inside the pipes, which could otherwise block the flow and cause damage to the pipeline system.

- Containers: For chemical containers used in transportation, the F53 Stainless Steel Coil provides a reliable solution. The containers made from this coil can protect the chemicals from external factors and ensure their safe delivery to the destination. The coil's formability allows for the creation of containers in different shapes and sizes to meet various transportation needs.

Company Background and Support

- Company History: Our company has a long - standing history in the special steel industry. Since its foundation in 2003, we have been focused on research and development and providing material solutions for power plant boiler steel. Over the years, we have continuously upgraded our technology and expanded our business. In 2017, we obtained important certifications such as ISO 9001:2015, API 5L, and EU PED, which enabled us to step into the international market. Our rich experience and technological advancements ensure that we can produce high - quality F53 Stainless Steel Coils.

- Expert Team: We have an expert team driving our business. Our CEO, Mr. Sang Le, has over 20 years of experience in the special steel industry and is well - versed in EU/US market compliance. Our Chief Metallurgist, Dr. Li Wei, holds a PhD in Materials Science from Tsinghua University and specializes in creep - resistant alloys and titanium metallurgy. Our technical staff includes 12 ASME - certified NDT Level III inspectors and 5 NADCAP - qualified engineers. This team ensures that our products are of the highest quality and meet international standards.

- Global Reach and Logistics: We serve a wide range of markets, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid - East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, and the domestic market. Our strategically located warehouses in Wuxi ensure rapid logistics, with 48 - hour delivery to major Chinese ports. This allows us to provide timely support to our international customers.

In conclusion, our F53 Stainless Steel Coil for chemical transport is a high - quality product with exceptional corrosion resistance. Its superior properties, combined with our company's strong background and support, make it an ideal choice for customers in the chemical transport industry.

Send Inquiry to This Supplier

You May Also Like

-

2507 Stainless Steel Coil for Oil & Gas Pipelines, 316LMOD/316Ti, With Corrosion and Fatigue ResistanceNegotiableMOQ: 1 Ton

-

F51 Stainless Steel Coil for Chemical Processing, S32950/316Ti, With Exceptional Mechanical PropertiesNegotiableMOQ: 1 Ton

-

316L Stainless Steel Coil for Electrical Equipment, F53/1.4547, Offering Heat Resistance and DurabilityNegotiableMOQ: 1 Ton

-

2507 Stainless Steel Coil for Structural Steel Construction, 31703/F44, With High StrengthNegotiableMOQ: 1 Ton

-

347H Stainless Steel Coil for Thermal Energy Equipment, S31803/316H, With High-Temperature ResistanceNegotiableMOQ: 1 Ton

-

ASTM AISI 201 304 316L 310S 409L 420 430 431 434 439 304 316 No. 1/2b/Ba/No. 4/Brushed/8K Mirror Stainless Steel Coil PriceNegotiableMOQ: 1 Ton

-

Stainless Steel Coil for Chemical Processing, 17-4PH/SUS630/2205, With High Corrosion ResistanceNegotiableMOQ: 1 Ton

-

17-7PH Stainless Steel Coil for Aerospace Applications, F51/316Ti, Offering Exceptional StrengthNegotiableMOQ: 1 Ton

-

SUS631 Stainless Steel Coil for Chemical Industry, F52/2507, With Superior Corrosion ResistanceNegotiableMOQ: 1 Ton

-

304H Stainless Steel Coil for Food Processing, 1.4529/316L, Offering Thermal StabilityNegotiableMOQ: 1 Ton