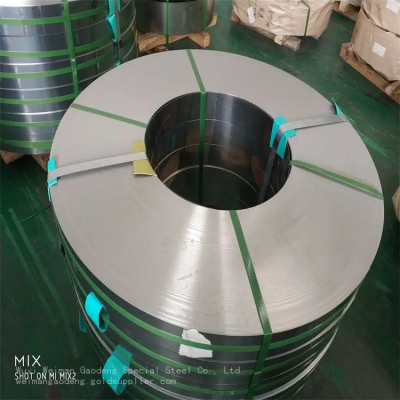

316Ti Stainless Steel Coil for High-Temperature Applications, F60/316L, in Harsh Environments

Introduction

Our 316Ti stainless steel coil, also known as F60/316L, is a top - notch product specifically designed for high - temperature applications in harsh environments. This coil is a result of advanced manufacturing techniques and strict quality control, making it an ideal choice for various industries around the globe.

Product Composition and Surface Treatment

The 316Ti stainless steel coil is primarily composed of iron, chromium, nickel, and molybdenum, with the addition of titanium. The titanium stabilizer helps prevent carbide precipitation during welding and high - temperature service, enhancing the corrosion resistance of the coil. The surface of the coil undergoes a polished treatment. This polished finish not only gives the coil an aesthetically pleasing appearance but also provides a smooth surface that is easier to clean and more resistant to the adhesion of contaminants.

Manufacturing Technique and Standard

This stainless steel coil is produced using the hot - rolled technique. Hot rolling allows the steel to be shaped at high temperatures, which improves its ductility and reduces internal stresses. The coil strictly adheres to the ASTM standard. ASTM standards are widely recognized and respected in the international market, ensuring that our product meets the highest quality and performance requirements. This compliance also means that our 316Ti stainless steel coil can be used in applications where strict quality control is necessary.

Performance in High - Temperature and Harsh Environments

One of the most outstanding features of our 316Ti stainless steel coil is its excellent performance in high - temperature environments. It can withstand elevated temperatures without significant loss of strength or corrosion resistance. This makes it suitable for use in industries such as power generation, chemical processing, and aerospace, where components are often exposed to high - temperature conditions.

In harsh environments, the coil shows remarkable corrosion resistance. It can resist corrosion from various chemicals, including acids, alkalis, and salts. Whether it is in a coastal area with high salt content in the air or a chemical plant with corrosive substances, our 316Ti stainless steel coil can maintain its integrity and performance over a long period.

Applications

- Chemical Industry: In chemical plants, the coil can be used to manufacture storage tanks, pipelines, and reaction vessels. Its corrosion resistance ensures that it can safely store and transport various chemicals without being corroded.

- Power Generation: For power plants, especially those using high - temperature steam or gas, the 316Ti stainless steel coil can be used in heat exchangers, boilers, and turbine components. Its high - temperature resistance and strength make it a reliable material for these critical applications.

- Aerospace: In the aerospace industry, where components need to withstand extreme conditions, our coil can be used in engine parts, exhaust systems, and structural components. Its light - weight yet strong properties contribute to the overall performance and safety of aerospace vehicles.

- Food and Beverage Industry: Due to its polished surface and excellent corrosion resistance, the coil is also suitable for use in food processing equipment, such as storage silos, conveyor belts, and mixing tanks. It meets the strict hygiene requirements of the food industry.

Company - Backed Assurance

Our company, a well - established manufacturer since 2017, has a wealth of experience and expertise in the production of stainless steel products. We have an annual export share ranging from US$5 Million - US$10 Million, which is a testament to the trust that international customers place in our products.

Our team consists of experienced professionals, including 11 - 20 sales representatives who are dedicated to providing excellent customer service. We have a wide range of services, from providing customized materials to offering value - added services. Our processing and testing capabilities are also top - notch. We can perform radiographic testing (RT) and liquid penetrant testing (PT) on welded elbows and flanges, and offer custom - cutting services for plates and pipes. Advanced NDT services, such as Ultrasonic Testing (UT) and Magnetic Particle Testing (MT), ensure the quality and integrity of our products.

With strategically located warehouses in Wuxi, we can ensure 48 - hour delivery to major Chinese ports, providing fast and reliable logistics support for our international customers. Our 316Ti stainless steel coil is a product that combines high - quality materials, advanced manufacturing, and excellent performance, making it a valuable choice for your high - temperature and harsh - environment applications.

Send Inquiry to This Supplier

You May Also Like

-

F51 Stainless Steel Coil for Chemical Processing, S32950/316Ti, With Exceptional Mechanical PropertiesNegotiableMOQ: 1 Ton

-

316L Stainless Steel Coil for Electrical Equipment, F53/1.4547, Offering Heat Resistance and DurabilityNegotiableMOQ: 1 Ton

-

2507 Stainless Steel Coil for Structural Steel Construction, 31703/F44, With High StrengthNegotiableMOQ: 1 Ton

-

347H Stainless Steel Coil for Thermal Energy Equipment, S31803/316H, With High-Temperature ResistanceNegotiableMOQ: 1 Ton

-

ASTM AISI 201 304 316L 310S 409L 420 430 431 434 439 304 316 No. 1/2b/Ba/No. 4/Brushed/8K Mirror Stainless Steel Coil PriceNegotiableMOQ: 1 Ton

-

Stainless Steel Coil for Chemical Processing, 17-4PH/SUS630/2205, With High Corrosion ResistanceNegotiableMOQ: 1 Ton

-

17-7PH Stainless Steel Coil for Aerospace Applications, F51/316Ti, Offering Exceptional StrengthNegotiableMOQ: 1 Ton

-

SUS631 Stainless Steel Coil for Chemical Industry, F52/2507, With Superior Corrosion ResistanceNegotiableMOQ: 1 Ton

-

304H Stainless Steel Coil for Food Processing, 1.4529/316L, Offering Thermal StabilityNegotiableMOQ: 1 Ton

-

17-4PH Stainless Steel Coil for High-Performance Heat Exchangers, F55/S32760, With Exceptional DurabilityNegotiableMOQ: 1 Ton