347H Stainless Steel Coil for Thermal Energy Equipment, S31803/316H, With High-Temperature Resistance

Introduction

Our 347H Stainless Steel Coil, along with S31803/316H options, is a top - notch product specifically designed for thermal energy equipment. With a focus on high - temperature resistance, these coils are engineered to meet the most demanding requirements of the thermal energy industry.

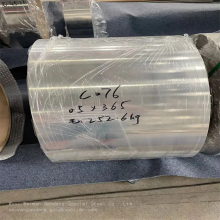

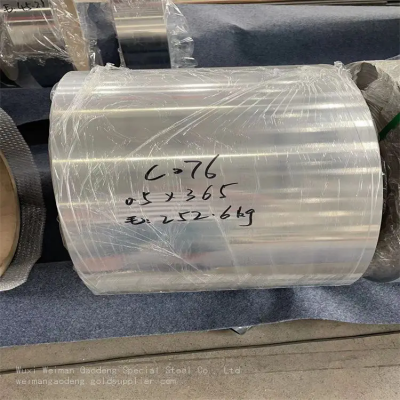

Product Specifications

- Surface Treatment: The coils undergo a polished surface treatment. This not only gives them an aesthetically pleasing appearance but also provides several functional benefits. A polished surface reduces friction, making it easier to clean and maintain. It also enhances the corrosion resistance of the stainless steel, protecting the coil from the harsh environments often found in thermal energy applications.

- Technique: These coils are hot - rolled. The hot - rolling process involves heating the steel above its recrystallization temperature and then rolling it to the desired thickness. This method results in a more uniform grain structure, which improves the mechanical properties of the steel. The hot - rolled coils have better ductility, making them more suitable for forming and shaping into various components for thermal energy equipment.

- Standard: Our coils adhere to the ASTM standard. ASTM standards are widely recognized and respected in the international market. By meeting these standards, our products ensure high quality, reliability, and compatibility with other components in thermal energy systems. This standardization also makes it easier for our customers to integrate our coils into their existing or new equipment designs.

High - Temperature Resistance

One of the most significant features of our 347H, S31803, and 316H stainless steel coils is their exceptional high - temperature resistance. In thermal energy equipment, such as boilers, heat exchangers, and furnaces, the coils are exposed to extremely high temperatures. The 347H grade contains niobium, which helps to stabilize the steel at high temperatures, preventing the formation of chromium carbides. This reduces the risk of intergranular corrosion, a common problem in high - temperature applications.

The S31803 grade, also known as duplex stainless steel, has a unique microstructure that combines austenite and ferrite phases. This gives it excellent strength and corrosion resistance at elevated temperatures. It can withstand high - temperature environments without significant loss of mechanical properties, making it ideal for use in thermal energy equipment where both strength and corrosion resistance are crucial.

The 316H grade is a high - carbon version of 316 stainless steel. It has improved high - temperature strength and creep resistance compared to standard 316 stainless steel. This makes it suitable for applications where the coil will be subjected to long - term high - temperature stress, such as in steam generators and superheaters.

Applications in Thermal Energy Equipment

- Boilers: Our stainless steel coils can be used in the construction of boiler tubes and headers. The high - temperature resistance ensures that the coils can withstand the intense heat generated inside the boiler, while the corrosion resistance protects them from the corrosive effects of steam and water. This helps to extend the lifespan of the boiler and improve its efficiency.

- Heat Exchangers: In heat exchangers, the coils transfer heat between two fluids. The high - temperature resistance of our coils allows them to operate effectively in high - temperature heat transfer applications. The polished surface also helps to improve the heat transfer efficiency by reducing fouling and scaling on the coil surface.

- Furnaces: Furnaces require materials that can withstand extremely high temperatures for extended periods. Our 347H, S31803, and 316H coils are well - suited for use in furnace linings, heating elements, and other components. Their high - temperature strength and corrosion resistance ensure reliable performance in the harsh furnace environment.

Company - Backed Quality

Our company, established in 2017, is a manufacturer with a strong focus on high - precision special steel solutions. We have an export share ranging from US$5 Million - US$10 Million, and our products are sold in major markets around the world, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, and our domestic market.

We have an expert team driving the quality of our products. Our CEO, Mr. Sang Le, has over 20 years of experience in the special steel industry, with in - depth knowledge of EU/US market compliance. Our Chief Metallurgist, Dr. Li Wei, holds a PhD in Materials Science from Tsinghua University and specializes in creep - resistant alloys and titanium metallurgy.

We also have advanced processing and testing capabilities. Our factory - made fabrication includes welded elbows and flanges per ASME B16.9, with radiographic testing (RT) and liquid penetrant testing (PT). We offer custom - cutting services for plates (max thickness 120mm) and pipes (OD 20 - 1200mm). Our advanced NDT services, such as Ultrasonic Testing (UT) to EN 10228 - 3 and Magnetic Particle Testing (MT) for surface cracks, ensure the quality and integrity of our stainless steel coils.

In conclusion, our 347H Stainless Steel Coil, along with S31803/316H options, is a reliable and high - performance choice for thermal energy equipment. With its high - temperature resistance, excellent quality, and our company's strong support, it is the ideal solution for your thermal energy needs.

Send Inquiry to This Supplier

You May Also Like

-

17-4PH Stainless Steel Coil for High-Performance Heat Exchangers, F55/S32760, With Exceptional DurabilityNegotiableMOQ: 1 Ton

-

F53 Stainless Steel Coil for High-Temperature Applications, S31254/316H, Offering Superior ResistanceNegotiableMOQ: 1 Ton

-

316Ti Stainless Steel Coil for Oil & Gas Industry, 2507/316H, With High Durability and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

S32750 Stainless Steel Coil for Food & Beverage Manufacturing, 317L/304H, With Precision and DurabilityNegotiableMOQ: 1 Ton

-

17-4PH Stainless Steel Coil for Medical Devices, F44/S20910, With Heat and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

S31803 Stainless Steel Coil for Marine Applications, 1.4460/S32205, With Excellent Wear ResistanceNegotiableMOQ: 1 Ton

-

316LMOD Stainless Steel Coil for Chemical Storage Tanks, 2205/347H, Offering Long-Lasting DurabilityNegotiableMOQ: 1 Ton

-

F60 Stainless Steel Coil for Pharmaceutical Equipment, 1.4547/316L, With Strength and SterilityNegotiableMOQ: 1 Ton

-

SUS329J1 Stainless Steel Coil for Automotive Manufacturing, 1.4435/S30409, With High Corrosion ResistanceNegotiableMOQ: 1 Ton

-

316Ti Stainless Steel Coil for Heat Exchangers, 1.4529/2507, With Exceptional Mechanical StrengthNegotiableMOQ: 1 Ton