316LMOD Stainless Steel Coil for Chemical Storage Tanks, 2205/347H, Offering Long-Lasting Durability

Introduction

Our 316LMOD Stainless Steel Coil, along with the options of 2205/347H, is a top - notch product specifically designed for chemical storage tanks. With a focus on long - lasting durability, this stainless steel coil is an ideal choice for industries that require reliable and high - performance materials for storing various chemicals.

Product Overview

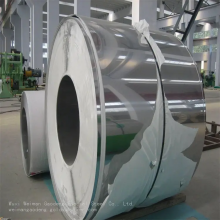

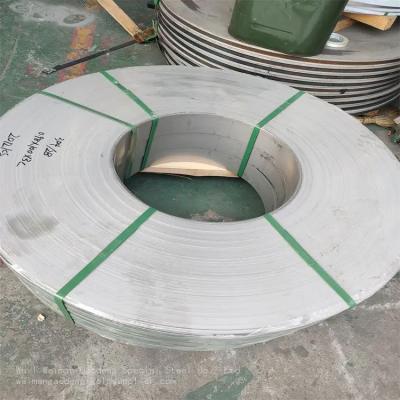

- Surface Treatment: The coil undergoes a polished surface treatment. This not only gives it an aesthetically pleasing appearance but also serves practical purposes. A polished surface reduces the adhesion of chemicals, making it easier to clean the storage tanks. It also enhances the corrosion resistance of the steel by minimizing the areas where chemical reactions can initiate.

- Technique: Employing the hot - rolled technique, the stainless steel coil gains several advantages. Hot rolling refines the grain structure of the steel, improving its mechanical properties such as strength and ductility. The process also allows for the production of coils with large dimensions, which is crucial for manufacturing large - scale chemical storage tanks.

- Standard: Our product adheres to the ASTM standard. This international standard ensures that the 316LMOD stainless steel coil meets rigorous quality and performance requirements. It provides assurance to our customers that the coil has been tested and verified for its chemical composition, mechanical properties, and other critical factors.

Material Properties

- 316LMOD Stainless Steel: This grade of stainless steel is well - known for its excellent corrosion resistance, especially in chloride - rich environments. The "L" in 316L indicates a low carbon content, which reduces the risk of carbide precipitation during welding, thus maintaining the corrosion resistance at the welds. The "MOD" modification further enhances its performance in chemical applications. It can withstand a wide range of corrosive chemicals, making it suitable for storing acids, alkalis, and other aggressive substances.

- 2205 Stainless Steel: 2205 is a duplex stainless steel that combines the benefits of austenitic and ferritic stainless steels. It has high strength, good resistance to stress - corrosion cracking, and excellent pitting and crevice corrosion resistance. In chemical storage tanks, 2205 can handle more demanding chemical environments and higher pressures compared to some other stainless steel grades.

- 347H Stainless Steel: The "H" in 347H stands for high - carbon, which gives this steel improved high - temperature strength. It is resistant to intergranular corrosion and is suitable for applications where the storage tanks may be exposed to elevated temperatures during the chemical storage or processing.

Applications in Chemical Storage Tanks

- Corrosion Resistance: Chemical storage tanks are constantly in contact with various corrosive substances. Our 316LMOD, 2205, and 347H stainless steel coils offer outstanding corrosion resistance, which extends the service life of the tanks. This reduces the frequency of tank replacements and maintenance costs, providing long - term cost savings for our customers.

- Strength and Durability: The high strength of these stainless steel grades allows the tanks to withstand the internal pressure exerted by the stored chemicals. Whether it is a large - scale industrial storage tank or a smaller laboratory - scale tank, our coils can ensure the structural integrity of the tank over an extended period.

- Hygiene and Cleanliness: In industries such as food and pharmaceutical chemicals, hygiene is of utmost importance. The polished surface of our stainless steel coils makes it easy to clean the tanks thoroughly, preventing the growth of bacteria and other contaminants. This ensures the purity of the stored chemicals.

Company - Backed Quality

- Manufacturing Expertise: We, Wuxi Weiman Gaodeng Special Steel Co., Ltd., are a manufacturer with a rich history and expertise in producing high - quality stainless steel products. Since our establishment in 2017, we have been committed to providing specialized high - precision special steel solutions.

- Global Reach: Our products have a significant export share, ranging from US$5 Million - US$10 Million. We serve major markets across the globe, including North America, South America, Europe, Asia, Africa, and Oceania. This global presence is a testament to the quality and reliability of our products.

- Advanced Services: We offer customized materials and value - added services for global industries. Our processing and testing capabilities are state - of the - art. We can perform advanced NDT (Non - Destructive Testing) services such as Ultrasonic Testing (UT) to detect internal defects as small as 0.5mm and Magnetic Particle Testing (MT) for surface cracks. Our welded elbows and flanges are produced per ASME B16.9 standards and are subject to radiographic testing (RT) and liquid penetrant testing (PT).

Technical Support and Logistics

- Expert Team: Our leadership team consists of experienced professionals. Mr. Sang Le, our CEO, has over 20 years of experience in the special steel industry and is well - versed in EU/US market compliance. Dr. Li Wei, our Chief Metallurgist, holds a PhD in Materials Science from Tsinghua University and specializes in creep - resistant alloys and titanium metallurgy. Our technical staff, including 12 ASME - certified NDT Level III inspectors and 5 NADCAP - qualified engineers, can provide comprehensive technical support to our customers.

- Rapid Logistics: We have strategically located warehouses in Wuxi, which ensures a 48 - hour delivery to major Chinese ports. This fast - paced logistics system allows us to meet the urgent needs of our international customers and ensures that the products reach them in a timely manner.

In conclusion, our 316LMOD Stainless Steel Coil, along with the 2205/347H options, is a reliable and high - performance solution for chemical storage tanks. With its long - lasting durability, excellent material properties, and the backing of our experienced company, it is the ideal choice for industries around the world.

Send Inquiry to This Supplier

You May Also Like

-

S32750 Stainless Steel Coil for Marine Applications, F52/347H, With Superior Stress ResistanceNegotiableMOQ: 1 Ton

-

S31668 Stainless Steel Coil for Power Plants, 1.4547/316H, With High-Temperature PerformanceNegotiableMOQ: 1 Ton

-

SUS329J1 Stainless Steel Coil for Aerospace Components, S34778/F51, Offering Strength and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

F53 Stainless Steel Coil for Chemical Transport, 1.4529/2507, With Exceptional Corrosion ResistanceNegotiableMOQ: 1 Ton

-

316Ti Stainless Steel Coil for High-Temperature Applications, F60/316L, in Harsh EnvironmentsNegotiableMOQ: 1 Ton

-

17-7PH Stainless Steel Coil for Pressure Vessel Manufacturing, S31803/304H, With High ToughnessNegotiableMOQ: 1 Ton

-

316L Stainless Steel Coil for High-Pressure Equipment, 1.4529/347H, Offering Durability and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

17-4PH Stainless Steel Coil for Heavy Industry Machinery, F44/2205, With Superior StrengthNegotiableMOQ: 1 Ton

-

1.4460 Stainless Steel Coil for Marine Equipment, SUS631/F52, With Wear and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

2507 Stainless Steel Coil for Oil & Gas Pipelines, 316LMOD/316Ti, With Corrosion and Fatigue ResistanceNegotiableMOQ: 1 Ton