Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating temperature

0°C to 60°C

Humidity

5% - 95% (non - condensing)

Power Input

24V DC

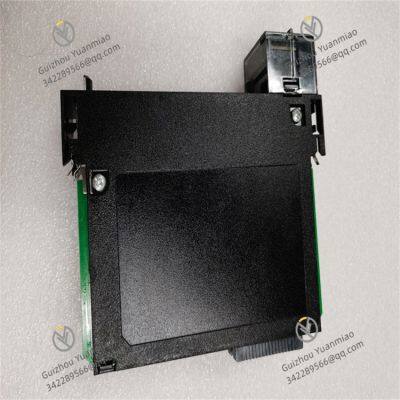

I. Overview

1756-IC16 is a high-performance analog input module in Rockwell Automation's ControlLogix series, mainly used for accurate collection of on-site analog signals in industrial automation systems. It can convert continuous analog signals (such as electrical representations of physical quantities like temperature, pressure, flow, and liquid level) from devices such as temperature sensors, pressure transmitters, and flow sensors into digital signals and transmit them to the ControlLogix processor, providing key raw data for the system's closed-loop control, data analysis, and process optimization.

This module is widely used in both process industries and discrete manufacturing. For example, in chemical production, it can collect temperature and pressure signals in reaction kettles; in the metallurgical industry, it can gather temperature and liquid level data of furnaces; in water treatment systems, it can monitor parameters such as pH value and turbidity of water quality. As an important part of the ControlLogix system, 1756-IC16 works collaboratively with processor modules and output modules to ensure that various key parameters in the industrial production process are monitored in real-time and accurately, providing strong support for the stable operation and quality control of production.

II. Technical Parameters

Number of Input Channels: Equipped with 16 independent analog input channels, which can collect 16 channels of analog signals simultaneously. It can meet the needs of multi-parameter monitoring in medium and large industrial equipment or production lines, reduce the number of modules used, and optimize the system structure.

Input Signal Types: Supports various common analog input signal types, including current signals (such as 4-20mA DC) and voltage signals (such as 0-10V DC, ±5V DC, etc.). The appropriate signal type can be selected through software configuration according to actual application scenarios, with strong compatibility, and can adapt to various industrial sensors and transmitters.

Resolution: Has a high resolution, usually 16 bits, which can accurately distinguish small signal changes, ensuring accurate collection of analog signals. For example, it can accurately capture subtle fluctuations in parameters such as pressure and temperature, providing high-precision data basis for the control system.

Accuracy: The measurement accuracy is high, generally within ±0.1% of the full scale (the specific accuracy value varies depending on the signal type and range). It can ensure the accuracy of collected data, reduce the impact of measurement errors on control decisions, and is suitable for industrial scenarios with high requirements for parameter accuracy.

Sampling Rate: The single-channel sampling rate can reach a high level, for example, each channel can sample hundreds of times per second (specific values refer to the product manual), and a stable rate can be maintained when multiple channels sample simultaneously. This ensures timely collection of rapidly changing analog signals, meeting the needs of real-time control.

Isolation Method: Adopts inter-channel isolation or group isolation design, with an isolation voltage usually of 250V AC. It can effectively suppress electromagnetic interference and common-mode interference between different channels, improve the anti-interference ability of the module in complex industrial electromagnetic environments, and ensure the stability of signal collection.

Power Requirements: Obtains power from the ControlLogix rack backplane, with low typical power consumption. For example, the current consumption is about 500mA at 5V DC (specific parameters are subject to the product data sheet), which has little impact on the system power load and ensures stable power supply to the system.

Environmental Adaptability Range:

Operating Temperature: Can work normally in the temperature range of 0°C to 60°C, adapting to temperature changes in industrial production sites, and can run stably in both high-temperature production workshops and normal-temperature control rooms.

Relative Humidity: Can withstand 5% to 95% non-condensing relative humidity, and can still maintain reliable signal collection performance in humid environments such as food processing workshops and water treatment plants.

Dimension Specifications: Adopts the standard module size of the ControlLogix series, perfectly matching the 1756 series rack, with convenient installation, no need for additional space adjustment, and easy system integration and later maintenance.

III. Functional Features

Multi-channel High-precision Collection: 16 input channels can simultaneously collect multiple analog signals with high precision, enabling centralized monitoring of various key parameters in the industrial production process. For example, in a chemical production line, it can collect temperature, pressure, and liquid level signals of multiple reaction tanks at the same time, reducing the number of modules used in the system, lowering costs, and simplifying on-site wiring.

Flexible Signal Adaptation: Supports multiple current and voltage signal types, and the signal type and range of each channel can be flexibly configured through software. It can adapt to different types of sensors and transmitters without replacing hardware, greatly improving the versatility and flexibility of the module, and adapting to diverse industrial application needs.

Fast Response and Real-time Monitoring: The high sampling rate ensures that the module can quickly capture dynamic changes of analog signals. For rapidly changing parameters (such as instantaneous pressure fluctuations, sudden temperature rises, etc.), it can collect and transmit them to the processor in a timely manner, enabling the control system to respond quickly and avoid production accidents caused by signal delay.

Reliable Anti-interference Ability: The isolation design between channels and good electromagnetic compatibility can effectively resist electromagnetic interference and common-mode interference in industrial sites, ensuring the purity and stability of collected signals, reducing measurement errors caused by interference, and ensuring that the control system makes decisions based on accurate data.

Comprehensive Diagnostic Functions: The module has self-diagnostic capability, which can monitor its own operating status (such as power failure, channel failure, etc.) and communicate with the processor through the backplane to report diagnostic information in real-time. At the same time, some modules also support the detection of faults such as sensor disconnection and short circuit, facilitating engineers to quickly locate and troubleshoot problems, and shortening the fault handling time.

Easy Integration and Configuration: As a standard module of the ControlLogix series, 1756-IC16 has excellent compatibility with other modules in the series and can be seamlessly integrated into the ControlLogix system. Through Rockwell Automation's Studio 5000 programming software, engineers can conveniently complete module parameter configuration (such as signal type, filtering parameters, etc.), channel calibration, and data mapping without complex programming, reducing the difficulty of system integration.

Industrial-grade Stability: Adopting industrial-grade components and a robust structural design, it has good anti-vibration and anti-impact performance, can withstand mechanical stress and environmental tests in industrial sites, ensures long-term stable operation in harsh industrial environments, and reduces production interruptions caused by module failures.

IV. Operation Guide

Installation Steps:

Preparation: Confirm that the installation environment meets the module's environmental adaptation requirements, and the rack power supply is turned off. Prepare necessary tools such as screwdrivers, and check whether the module's appearance is intact and the connectors are damaged.

Rack Installation: Align the 1756-IC16 module with the idle slot of the ControlLogix 1756 series rack, push it in smoothly along the guide rail until the module is in close contact with the rack backplane, then fix both sides of the module with screws to prevent the module from loosening.

Wiring Connection: According to the module's wiring diagram and the signal type of the sensor/transmitter, use shielded wires to connect the output signal of the external device to the corresponding input terminal of the module. Pay attention to distinguishing the positive and negative polarities of the signal and the ground terminal, ensure the wiring is firm and correct, and the shield layer should be properly grounded to enhance anti-interference ability. After wiring, carefully check whether the wiring is correct.

Power On: After confirming that all connections are correct, turn on the rack power supply, the module will start initialization, and at this time, the status indicator of the module can be observed to determine whether the module starts normally.

Configuration Process:

Software Preparation: Install Studio 5000 software on the programming computer and ensure that the software version is compatible with the module. Connect the computer to the ControlLogix processor through a programming cable to establish a communication connection.

Module Addition: Open the corresponding project in Studio 5000 software, enter the I/O configuration interface, add the 1756-IC16 module according to the actual installation position of the module in the rack, and the software will automatically identify the module model.

Parameter Configuration: According to the signal type of the sensor/transmitter in actual application (such as 4-20mA, 0-10V, etc.), configure the corresponding signal type and range for each channel in the software. At the same time, signal filtering parameters (such as filtering time) can be set as needed to reduce the impact of signal noise.

Channel Calibration: For application scenarios with extremely high precision requirements, each channel of the module can be calibrated through software (including zero calibration and full-scale calibration) to ensure the accuracy of collected data. The calibration process requires the use of a standard signal source and follows the software prompts for step-by-step operation.

Data Mapping: Associate the data collected by each channel of the module with the internal tags of the processor, so that the processor can read and process the collected analog data. After completing the configuration, download the project to the ControlLogix processor.

Troubleshooting:

Abnormal Signal Collection: If the data collected by a certain channel is inaccurate or there is no signal, first check whether the external sensor/transmitter is working normally and whether the output signal is within the range of the module. Check whether the wiring is firm and correct, and whether the shield layer is well grounded. A multimeter or signal generator can be used to detect the input signal to rule out problems with external equipment and wiring. If the external is normal, try to recalibrate the channel or check whether the module has a channel fault.

Abnormal Status Indicator: If the status indicator of the module shows abnormally (such as the fault light is on), the diagnostic information of the module can be viewed through Studio 5000 software to obtain the specific cause of the fault (such as power failure, channel overload, etc.), and targeted treatment can be carried out according to the prompts.

Communication Fault: If the processor cannot read the module's data or configuration information, check whether the connection between the module and the rack backplane is tight and whether the communication between the computer and the processor is normal. You can try to re-download the configuration or replace the module slot for testing to rule out poor contact or communication link problems.

Overall Module Fault: If the module cannot start or has a serious fault, and after ruling out problems such as power supply, wiring, and configuration, it may be that the module hardware is damaged, and professional maintenance personnel should be contacted for repair or replacement.