Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating temperature

0°C to +60°C (32°F to 140°F)

Humidity

5% - 95% (non - condensing)

Power Input

24V DC

I. Overview

1756-L8SP is a safety partner controller in the GuardLogix controller product series under the Allen-Bradley brand of Rockwell Automation. As a key component in industrial automation systems, it does not operate independently but works in collaboration with the main GuardLogix safety controller to build a highly reliable safety control architecture. By pairing with specific main controllers (such as 1756-L71S, 1756-L71SK, 1756-L72S, 1756-L72SK, 1756-L73S, 1756-L73SK), it forms a 1oo2 safety architecture, which can meet the strict functional requirements of Safety Integrity Level 3 (SIL 3) and Performance Level e (PL e). It is widely used in industrial scenarios with extremely high requirements for personnel safety, equipment protection, and production continuity, such as production line control in chemical, energy, automotive manufacturing and other industries.

II. Technical Parameters

Current Consumption: It exhibits different current consumption characteristics under different voltages, 5 mA at 1.2 V DC and 800 mA at 5.1 V DC. This low current consumption design helps reduce the overall power consumption of the system, improve energy efficiency, and is especially suitable for industrial automation systems sensitive to power consumption.

Power Consumption: The rated power consumption is only 2.5 watts. Low power consumption means less heat is generated during long-term operation, which not only reduces the demand for cooling equipment but also improves the stability and reliability of the module itself, reducing the risk of failures caused by overheating.

Heat Dissipation: It dissipates 8.5 BTU per hour. The efficient heat dissipation capability ensures that the module can maintain within an appropriate operating temperature range even under high-load operation, ensuring the stable operation of the system and adapting to the complex and variable environment of industrial sites.

Isolation Voltage: It has a continuous isolation voltage of 30 volts, and the basic insulation from the USB port to the system has passed a type test at 980 V AC for 60 seconds. The strong isolation performance effectively prevents the impact of external electrical interference on the internal circuits of the module, enhances the anti-interference ability of the system in complex electromagnetic environments, and ensures the accuracy of data transmission and the reliable execution of control commands.

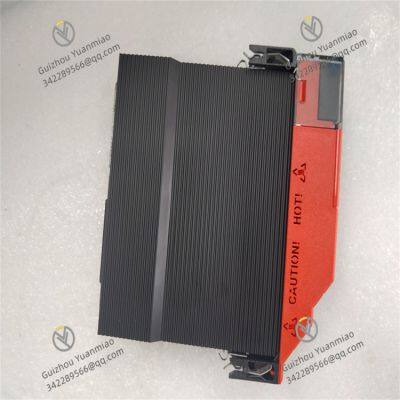

Size and Slots: It adopts a dual-slot width design and can be installed in any available slot of the 1756 series chassis, but must be installed next to the main controller to form an effective 1oo2 architecture. This specific installation position requirement ensures the efficiency of communication and the timeliness of data synchronization between the main and standby controllers.

Environmental Adaptability:

Operating Temperature: The operating temperature range is 0°C to +60°C (32°F to 140°F), which can adapt to temperature changes in most industrial production sites, and can operate stably whether in high-temperature smelting workshops or normal-temperature electronic assembly workshops.

Storage Temperature: The storage temperature range is -40°C to +85°C (-40°F to +185°F). Even when stored for a long time in extreme environments, the module performance is not affected, facilitating inventory management and long-term backup of equipment.

Relative Humidity: It can withstand 5% to 95% non-condensing relative humidity, and can still maintain good electrical performance and operational reliability in humid environments (such as food processing workshops, textile factories).

Communication and Programming: It supports standard EtherNet/IP, DeviceNet, and ControlNet safety communication options, facilitating high-speed and reliable data interaction with other industrial equipment. At the same time, it uses relay ladder logic (RLL), structured text, and sequential function chart (SFC) programming languages, providing engineers with diverse programming methods to meet the development needs of control logic with different complexity levels.

III. Functional Features

High Safety Architecture: It cooperates with the main GuardLogix safety controller to form a 1oo2 architecture, realizing redundant control of safety functions. When the main controller fails, 1756-L8SP can quickly take over the control tasks, ensuring that safety-related equipment (such as emergency braking systems, safety light curtains, etc.) continue to work normally, preventing accidents, and ensuring the safety of personnel and equipment.

Flexible Compatibility: It is compatible with a variety of main controllers and energy storage modules (such as 1756-SPESMNSE capacitor energy storage module for safety partners, 1756-SPESMN RM non-removable energy storage module), and can also adapt to various chassis (such as 1756-A4, 1756-A7, etc.) and power supplies (such as 1756-PA50, 1756-PB72, etc.) of the 1756 series. It provides great flexibility for system integration, facilitating customized configuration according to the needs of different industrial scenarios.

Memory Correspondence Mechanism: Although it has no independent dedicated memory, its memory corresponds to the main controller. Under the unified management of the main controller, efficient data storage and calling are realized, which not only avoids the waste of memory resources but also ensures the consistency and synchronization of data between the main and standby controllers.

Convenient Communication Function: It integrates a variety of standard industrial communication interfaces. With the help of communication protocols such as EtherNet/IP, DeviceNet, and ControlNet, it can quickly and stably exchange data with other devices in the system, realizing remote monitoring, centralized management, and collaborative control between different production links, and improving the intelligence level of the entire industrial automation system.

Rich Programming Modes: It supports multiple programming languages. Engineers can flexibly choose relay ladder logic (RLL), structured text, or sequential function chart (SFC) for program development according to project requirements and their own programming habits, reducing programming difficulty, improving development efficiency, and facilitating accurate description and implementation of complex industrial control processes.

IV. Common Faults and Solutions

Communication Fault:

Overheating Fault:

Power Fault:

Compatibility Fault: