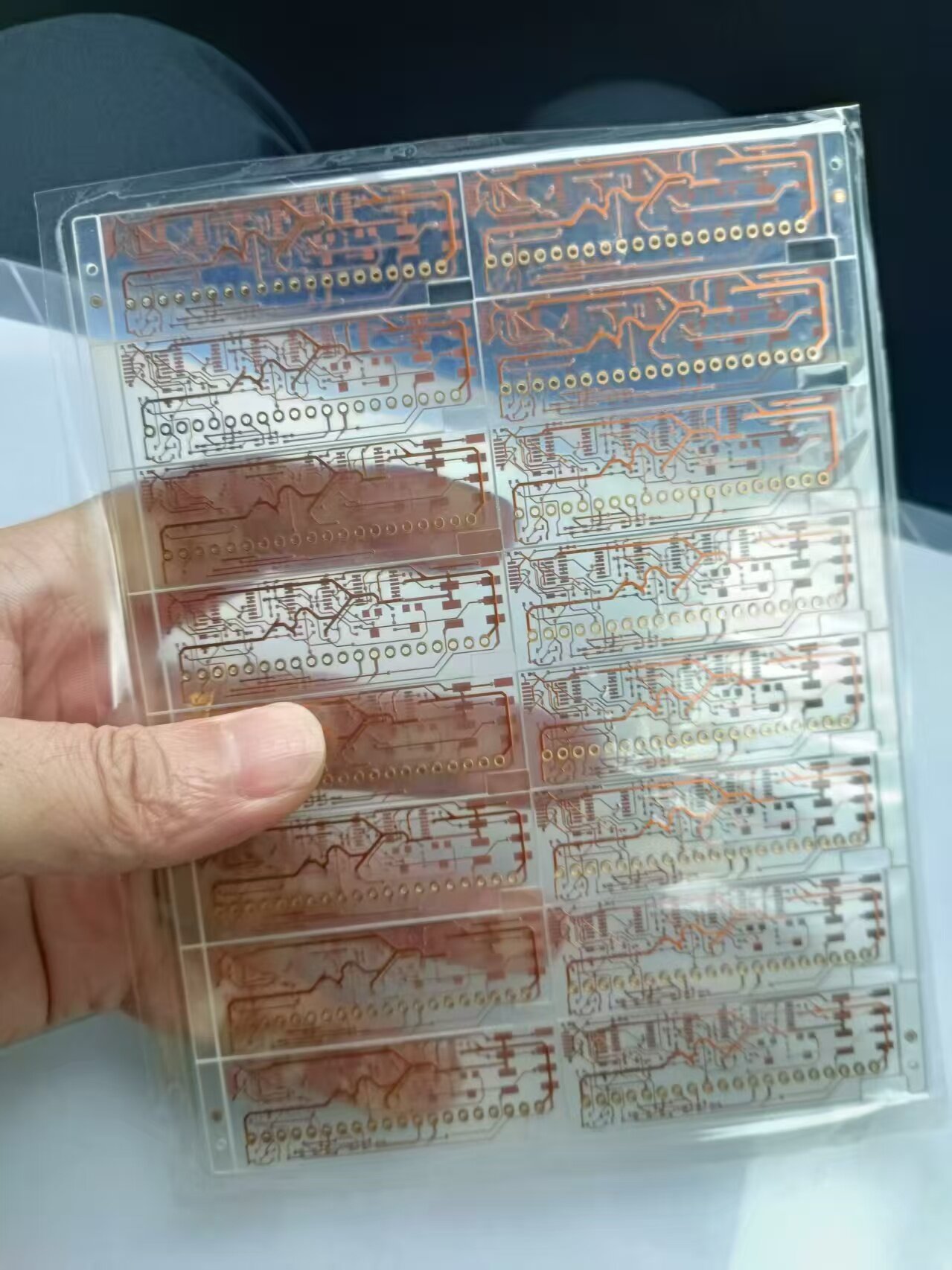

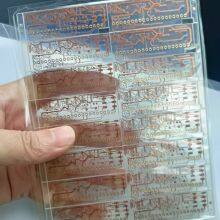

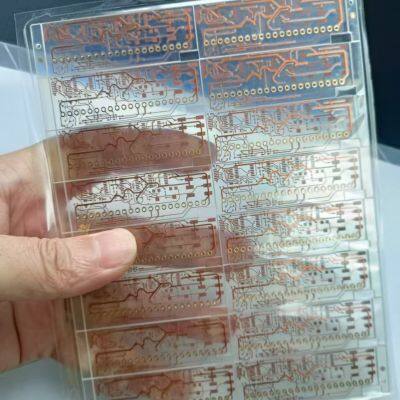

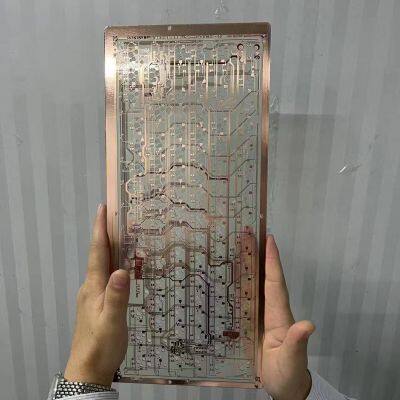

Transparent FR-4PCB,FR-4, TG130 Material,PI Transparent Flexible Board FPC

Product Name: Transparent FR-4PCB

Board: FR-4, TG130 material

Number of floors: 2

Minimum line width/spacing: 12/12mil

Finished product size: 250x1200mm

Surface technology: Sinking gold

Copper thickness: 35um

Plate thickness: 1.60mm

Minimum hole: 0.50mm

Features: Transparency meets 85-95% and can withstand normal temperatures of 220-240 degrees Celsius

Usage: Large size, LED transparent screen, display frequency, LED glass screen, etc

Detailed Introduction to Transparent FR-4 Multilayer PCB

Material characteristics

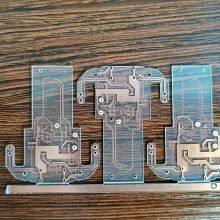

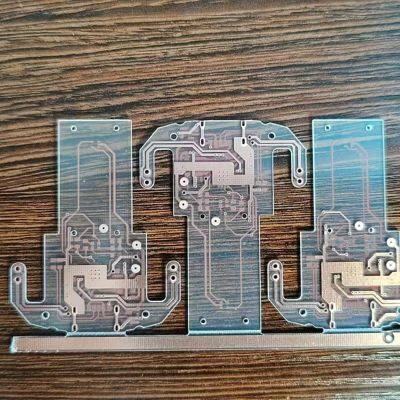

High transparency: Using special transparent FR-4 material, the transparency can reach 85% -92%, which can clearly display the internal circuit layout and component arrangement, bringing unique visual effects to product design.

Good electrical performance: Similar to ordinary FR-4 material, it has excellent electrical insulation performance, which can effectively prevent current leakage and electromagnetic interference, ensuring stable operation of PCB in complex electrical environments.

High mechanical strength: The glass fiber reinforced epoxy resin laminated board endows the transparent FR-4 multi-layer PCB with good mechanical strength, enabling it to withstand certain external impacts and vibrations, and is not easily deformed or damaged, making it suitable for various application scenarios.

Heat resistance: The heat resistance temperature range is usually between 130 ℃ and 180 ℃, which can maintain the stability of its structure and performance in higher temperature environments and adapt to different working environments.

Flame retardancy: As a flame-retardant material, FR-4 has flame-retardant properties and can self extinguish when burned, improving the safety of PCB use and complying with relevant safety standards 2.

manufacturing process

High precision etching: Through high-precision exposure and etching processes, the transparent conductive layer is precisely processed to ensure that the line width and spacing accuracy of the circuit pattern meet the design requirements, usually up to 3/3mil or even smaller, ensuring the accuracy and consistency of the circuit.

Laminated process: Advanced laminating technology is one of the key steps in manufacturing transparent FR-4 multilayer PCBs, which requires ensuring tight bonding between layers to avoid problems such as bubbles and stress concentration. At the same time, it is required that the alignment error between layers be less than 10 μ m to ensure the performance and reliability of the multilayer board.

Surface treatment: According to different application requirements, various surface treatment methods are provided, such as OSP (organic solder mask), gold deposition, tin spraying, etc., which can improve the oxidation resistance, solderability, and wear resistance of the circuit board surface.

Application Area 1

Intelligent display: such as transparent display screens, smart glass, etc. The transparent FR-4 multi-layer PCB provides a transparent circuit solution for display devices, making the display effect more unique and beautiful, while also achieving higher integration and functionality.

Automotive electronics: Used for intelligent instrument panels, head up displays, and other components in cars, which can enhance the driving experience and bring more innovative space to car interior design, making the electronic devices in the car more integrated with the overall interior style.

High end consumer electronics: In products such as smartphones, tablets, wearable devices, etc., transparent FR-4 multi-layer PCB can provide more creativity for product design, showcase the technological and exquisite sense of the product, and meet consumers' needs for personalization and aesthetics.

Medical equipment: In the fields of medical imaging equipment, medical monitoring instruments, etc., transparent PCBs can provide clearer image transmission and signal processing, which helps doctors to diagnose and treat more accurately, and also facilitates equipment maintenance and repair.

| Transparent FR- 4 material layers | 1-2layer | 1-2layer | 1-8layer | |

| Transparent FR-4 minimum hole | 0.35mm | 0.35mm | 0.35mm | |

| Transparent FR-4 minimum line width and spacing | 4/4Mil | 4/4Mil | 3.5/3.5Mil | |

| Transparent FR- 4 maximum size | 23.63*47.25″ | 23.63*47.25 ″ | 23.63*47.25 ″ | |

| Number of tempered glass base layers | 1-2layer | 1-2layer | 1-2layer | |

| Minimum line width and spacing of glass | 4/4Mil | 4/4Mil | 3.5/3.5Mil | |

| The smallest hole in glass | 0.35mm | 0.35mm | 0.35mm | |

| Maximum size of glass | 23.63*47.25″ | 23.63*47.25 ″ | 23.63*47.25 ″ | |

| Number of layers of transparent PETmaterial | 1-2layer | 1-2layer | 1-2layer | |

| Maximum size of transparent PET | 19.68 ″*7874" | 19.68 ″*7874" | 19.68 ″*7874" | |

The company's main product types | Halogen free materials, high TG materials, high-frequency materials, high-speed materials, metal materials, glass materials, embedded materials, transparent FR- 4 materials, high thermal conductivity metals, high thermal conductivity aluminum substrates, environmentally friendly circuit boards, BT materials, ABF materials, and other imported materials, DU busbars, iron-based and metal based (core) mixed pressure plates, embedded buried copper, buried resistors, buried capacitors, buried ceramic bead plates, buried ceramics, ceramic mixed pressure plates, multi-layer ceramics, ultra-thin BT plates, ultra-thin PCBs, ultra-thin PCBs, multi-layer aluminum substrates, multi-layer ceramic plates, multi-layer ultra-thin HDI、 High frequency mixed voltage, differential impedance board, thick copper plate, gold-plated plate, high and low copper, high and low copper, high carbon resistance, transparent multilayer, glass plate, HDI arbitrary order (cross blind buried) Anylayer, flexible double-sided, flexible multilayer, soft hard combination HDI, roll to roll FPC, ultra long size, ultra large size board (single, double, multi-layer) PCB production and product design, product development, software development, etc | |||

| Main material | Rogers, Taikoni, Yaron, Mitsui, Isola, 3M, Taiyao, Taiguang, Tenghui, Shengyi,Lianmao, Nanya, Doosan, DuPont, Taihong, Hongren, Xinyang, Nippon Steel, Teflon,Yasen, Panasonic, RCC, Mitsui, Mitsubishi, Yingye, 3M, Kyocera, Jiuhao, Zhongci,Huaqing, Aishengda, Sliton, Kaichangde, Tongxin, Beige, Yalong, Taikoni,Hitachi, Laird System, etc | |||

Main material categories | Halogen-free、halogenated、 high thermal conductivity, high TG135 、TG140、 TG150、 TG170、TG180、TG240、TG320 | |||

| Build-up Material | FR-4 ,TG150,TG70,TG180 | |||

| Conventional plate thickness (mm) | Min.1-2L(mm) | 0.10mm | 0.10-12.0mm | 0.10-18.0mm |

| Min.4-10L(mm) | 0.35mm | 0.35mm~10.0mm | 0.35-18.0mm | |

| Min.12L(mm) | 0.43 | 0.38~10.0mm | 0.38~18.0mm | |

| Min.16L(mm) | 0.53 | 0.45~10.0mm | 0.45~18.0mm | |

| Min.18L(mm) | 0.63 | 0.51~10.0mm | 0.51~18.0mm | |

| Min.52L(mm) | 0.8 | 0.65~10.0mm | 0.65~18.0mm | |

| MAX(mm) | 3.5 | 12.0mm | 18.0mm | |

Send Inquiry to This Supplier

You May Also Like

-

Film Switch Transparent PET Silver Wire FPCNegotiableMOQ: 1 Blade

-

1-6 Transparent FR-4 Circuit Board PCBNegotiableMOQ: 1 Blade

-

6 Transparent FR-4 Circuit Boards PCBNegotiableMOQ: 1 Blade

-

Transparent Glass Circuit Board PCB, Copper Wiring Transparent Glass PCBNegotiableMOQ: 1 Blade

-

Transparent Tempered Glass Circuit Board PCB, Copper WiringNegotiableMOQ: 1 Blade

-

Tempered Glass PCB Glass PCBNegotiableMOQ: 1 Blade

-

Double Layer Transparent FR-4PCB,Multi Layer FR-4 Transparent PCB,Is the Cost of Producing Multi-layer Transparent CircuitNegotiableMOQ: 1 Unit

-

Blind Buried Hole HDI Flexible FPC,4-layer Flexible FPCNegotiableMOQ: 1 Unit

-

12 Layers of Flexible Multi-layer,soft Hard Combined FPC,Mobile Phone Motherboard, Touch ScreenNegotiableMOQ: 1 Unit

-

Aviation Bluetooth Glasses,16 Layers HDI 4th OrderNegotiableMOQ: 1 Unit