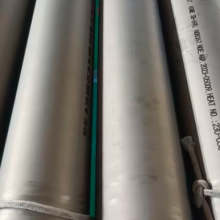

ASME SA312 Tp317L 1.4438 Stainless Steel Welded Pipe High Temperature

To ensure the tubes meet the required standards, they are subjected to several tests like the Product Analysis, Hardness, Mechanical, Flattening, Flaring,

Hydrostatic, or NDT tests, based on the client’s test requirements. The tubes must also conform to the applicable provisions of the current edition of Specification A 450/A 450M.

The ASTM A179 Tubes come in different sizes and varying wall thicknesses, and U-bending tubes can also be offered. Additionally, the tubes are subject to various test requirements, including ASTM A179 Tubes (ASME SA179 Tubes) Chemical Compositions, Mechanical Properties, Wall Thickness Tolerance, Outside Diameter Tolerance, Cut Length Tolerance, and Hydrostatic Test Pressures, to ensure quality.

Widely used in petroleum, chemical, medical, food, light industry, Industrial pipes and mechanical structural parts such as mechanical meters. In addition, when the bending and torsion strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts. And engineering structure.It is also often used as furniture and kitchen utensils.

Send Inquiry to This Supplier

You May Also Like

-

ASTM A312/A213 Stainless Steel Welded PipeUS$ 22 - 30MOQ: 100 Kilograms

-

ASTM A312/A213/A269 304/310/316/347/321 Stainless Steel Tube Ss Smls TubeUS$ 22 - 30MOQ: 100 Kilograms

-

ASTM A213 ASTM SA213 TP304 304L 316L 321 317L 310S 309S 2205 S31803 Seamless Stainless Steel Pipe TubeUS$ 22 - 30MOQ: 100 Kilograms

-

ASTM A213 Tp316L Stainless Steel Seamless Tube Pipe PriceNegotiableMOQ: 500 Kilograms

-

ASTM A213 Tp321 Seamless Stainless Steel Pipe TubeNegotiableMOQ: 500 Kilograms

-

ASTM A213 Tp321 Seamless Stainless Steel Pipe TubeUS$ 22 - 30MOQ: 100 Kilograms

-

Seamless Stainless Steel Pipe Tube ASTM A213/A213m ASTM A312/312m /JIS G3459 / DIN2462 /DIN17006 / DIN17007NegotiableMOQ: 2000 Kilograms

-

ASTM A213 Ss310s 310h 317 317L 321 321H 347 347H 904L Seamless Stainless Steel Pipes TubeNegotiableMOQ: 2000 Kilograms

-

ASTM A213 316L Seamless Stainless Steel TubeNegotiableMOQ: 500 Kilograms

-

Seamless Stainless Steel Pipe ASTM A213 316L Seamless Stainless Steel TubeNegotiableMOQ: 500 Kilograms