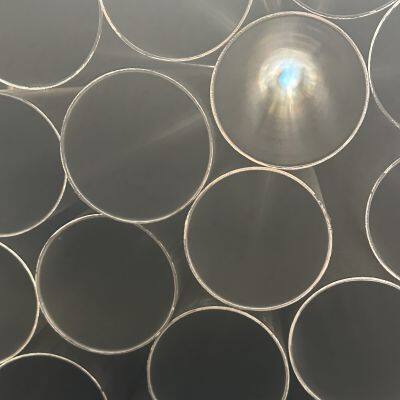

Cold / Hot Rolled Seamless Stainless Steel Pipe Ss Steel Tube ASTM A312 A213 TP304/304L 316/316L Stainless Steel Pipe

boiler and super-heater tubes and austenitic steel heat-exchanger tubes, designated Grades TP304,TP304H,TP304L,TP310S, TP310HCbN, TP316, TP316H, TP316L etc.

Grades TP304H, TP309H, TP309HCb, TP310H, TP310HCb, TP310HCbN, TP316H, TP321H, TP347H, TP347HFG (fine grained) and TP348H are modifications of Grades TP304, TP309S, TP309Cb, TP310S, TP310Cb, TP316, TP321, TP347, and TP348, and are intended for high-temperature service, such as for superheaters and reheaters.

For ASTM A213 Seamless Tubes with diameters less than 1/8 in. [3.2 mm] in inside diameter or 0.015 in. [0.4 mm] in thickness,mechanical property requirements won’t apply. Tube with other dimensions may be furnished comply with other requirements.

ASTMA 213 is an American Society for Testing and Materials (ASTM) standard for the specification of technical requirements and quality standards for seamless ferritic and austenitic alloy steel tubes and tubes for boilers, superheaters, and heat exchangers, the tubes are manufactured in seamless process in hot finished or cold finished in a wide range of sizes.

The ASTMA 213 standard applies to seamless ferritic and austenitic alloy steel tubes of minimum wall thicknesses, primarily for boilers, superheaters, and heat exchangers. The standard covers a wide range of tube grades including, but not limited to, T11, T12, T22 tubes, TP304, TP316L, TP321 tubes, etc. Detailed specifications for these tubes are listed in the relevant sections of the standard, containing grade, size, finishes, test and other terms, the equivalent standard is ASME SA213, and the latest version of the standard is ASTM A213/A213M-22.

ASTM A213 GradesASTM A213 Specification covers various grades containing alloy steels, Ferritic and Austenitic steels, Austenitic stainless steel is the most used group due to its properties, common designated grades are listed, chemical composition, mechanical properties and solution temperature provided.

Alloy grades: T5, T9, T11, T12, T22, T36and T91 etc

Ferritic steels: TP444

Austenitic stainless steels: TP304, TP304L, TP304H, TP309S, TP309H, TP310S, TP310H,TP316, TP316L, TP316H, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP348, TP348H.etc

ASTM A213 Chemical Composition| Grade | C | Si | Mn | Cr | Ni | Mo | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Max, % | Max, % | Max, % | % | % | % | Max, % | Max, % | % | |

| TP304 | 0,08 | 1,0 | 2 | 18 – 20 | 8 – 11 | – | 0,03 | 0,045 | Bal |

| TP304L | 0,035 | 1,0 | 2 | 18 – 20 | 8 – 12 | – | 0,03 | 0,045 | Bal |

| TP316 | 0,08 | 1,0 | 2 | 16 – 18 | 11 – 14 | 2 – 3 | 0,03 | 0,045 | Bal |

| TP316L | 0,035 | 1,0 | 2 | 16 – 18 | 10 – 14 | 2 – 3 | 0,03 | 0,045 | Bal |

| TP321 | 0,08 | 1,0 | 2 | 17 – 19 | 9 – 12 | – | 0,03 | 0,045 | Bal |

| Grade | Tensile Strength | Yield Point | Elongation | Hardness(HRB) | Solution Temperature |

|---|---|---|---|---|---|

| Min, Mpa | Min, Mpa | Min, % | Max Rockwell | Min, oC, | |

| TP304 | 515 | 205 | 35 | 90 | 1040 |

| TP304L | 485 | 170 | 35 | 90 | 1040 |

| TP316 | 515 | 205 | 35 | 90 | 1040 |

| TP316L | 485 | 170 | 35 | 90 | 1040 |

| TP321 | 515 | 205 | 35 | 90 | 1040 |

ASTM A213 sizes usually furnished to this specification are 1/8 inch [3.2 mm] in inside diameter to 5 inch [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm]. Common outside diameter and wall thickness are listed as below, tubing having other diameters may be furnished, provided such tubes comply with all other requirements of this specification.

Outside Diameter in mm15.8, 16.0, 19.05, 22, 25, 28, 38.1, 57, 60.3, 76.2, 88.9, 101.6 mm etc.

Wall Thickness in mm0.889, 1.245, 1.651, 2.0, 2.11, 2.769, 3.404mm, etc

Metric, Fractional and Gauge Sizes| Outside Diameter | Outside Diameter | BWG | BWG | BWG | BWG | BWG | BWG | BWG | BWG |

|---|---|---|---|---|---|---|---|---|---|

| 25 | 22 | 20 | 18 | 16 | 14 | 12 | 10 | ||

| WT mm | WT mm | WT mm | WT mm | WT mm | WT mm | WT mm | WT mm | ||

| 0.508 | 0.71 | 0.89 | 1.24 | 1.65 | 2.11 | 2.77 | 3.40 | ||

| mm | inch | kg/m | kg/m | kg/m | kg/m | kg/m | kg/m | kg/m | kg/m |

| 6.35 | 1/4 | 0.081 | 0.109 | 0.133 | 0.174 | 0.212 | |||

| 9.53 | 3/8 | 0.126 | 0.157 | 0.193 | 0.257 | 0.356 | 0.429 | ||

| 12.7 | 1/2 | 0.214 | 0.263 | 0.356 | 0.457 | 0.612 | 0.754 | ||

| 15.88 | 5/8 | 0.271 | 0.334 | 0.455 | 0.588 | 0.796 | 0.995 | ||

| 19.05 | 3/4 | 0.327 | 0.405 | 0.553 | 0.729 | 0.895 | 1.236 | ||

| 25.4 | 1 | 0.44 | 0.546 | 0.75 | 0.981 | 1.234 | 1.574 | 2.05 | |

| 31.75 | 1 1/4 | 0.554 | 0.688 | 0.947 | 1.244 | 1.574 | 2.014 | 2.641 | |

| 38.1 | 1 1/2 | 0.667 | 0.832 | 1.144 | 1.514 | 1.904 | 2.454 | 3.233 | |

| 44.5 | 1 3/4 | 1.342 | 1.774 | 2.244 | 2.894 | 3.5 | |||

| 50.8 | 2 | 1.549 | 2.034 | 2.574 | 3.334 | 4.03 | |||

| 63.5 | 2 1/2 | 1.949 | 2.554 | 3.244 | 4.214 | 5.13 | |||

| 76.2 | 3 | 2.345 | 3.084 | 3.914 | 5.094 | 6.19 | |||

| 88.9 | 3 1/2 | 2.729 | 3.609 | 4.584 | 5.974 | 7.27 | |||

| 101.6 | 4 | 4.134 | 5.254 | 6.854 | 8.35 | ||||

| 114.3 | 4 1/2 | 4.654 | 5.924 | 7.734 | 9.43 |

| OD | OD Tolerance | OD Tolerance | WT Tolerance | WT Tolerance | Length Tolerance | Length Tolerance |

|---|---|---|---|---|---|---|

| mm | Over | Under | Over | Under | Over | Under |

| Under 25.4 | 0.1016 | 0.1016 | +20 | -0 | 3.175 | 0 |

| 25.4-38.1 incl | 0.1524 | 0.1524 | +20 | -0 | 3.175 | 0 |

| 38.1-50.8 excl | 0.2032 | 0.2032 | +22 | -0 | 3.176 | 0 |

| 50.8-63.5 excl | 0.254 | 0.254 | +22 | -0 | 4.46 | 0 |

| 63.5-76.2 excl | 0.3048 | 0.3048 | +22 | -0 | 4.76 | 0 |

| 76.2-101.6 incl | 0.381 | 0.381 | +22 | -0 | 4.76 | 0 |

| 101.6-190.5 incl | 0.381 | 0.635 | +22 | -0 | 4.76 | 0 |

| 190.5-228.6 incl | 0.381 | 1.143 | +22 | -0 | 4.76 | 0 |

| Outside Diameter, mm | Tolerance, mm |

|---|---|

| OD≤101.6 | +0.4/-0.8 |

| 101.6<OD≤190.5 | +0.4/-1.2 |

| 190.5<OD≤228.6 | +0.4/-1.6 |

| Outside Diameter, mm | Tolerance, % |

|---|---|

| OD≤101.6, WT≤2.4 | +40/-0 |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 |

| OD≤101.6, WT>4.6 | +28/-0 |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 |

| OD>101.6, WT>4.6 | +28/-0 |

The tubes shall be produced through the hot-finished or cold-finished seamless process.

Heat treatment shall be done separately and in addition to heating for hot forming.

The ferritic alloy and ferritic stainless steels shall be reheated. austenitic stainless steel tubes shall be furnished in the heat-treated condition.

Tubes may be individually quenched in water or rapidly cooled by other means.

Tubes shall be pickled free of scale. When bright annealing is used, pickling is not necessary.

Complete tests should be conducted conforming to ASTM A213 or ASTM A1016.

We are a professional ASTM A213 seamless tube manufacturer & supplier, having the capability to produce a wide range size seamless tubes for heat exchanger systems, the manufacturing process starts from the extrusion of the billet, by cold rolling and cold drawn methods to control size and tolerance, heat treatment will be finished after cold working to achieve original steel properties, which improve high-temperature resistance and corrosion resistance, then tubes should be under pickling passivation condition.

| A213 Alloy Steel Seamless Tubes Specification | ASTM A213 / ASME SA213 |

| A213 Alloy Steel Seamless Tubes Grades | ASTM A213 T5, ASTM A213 T9, ASTM A335 T11, ASTM A213 T22, ASTM A335 T91, ASME SA213 T5, ASME SA213 T9, ASME SA213 T11, ASME SA213 T22, ASME SA213 T91 |

| A213 Alloy Steel Seamless Tubes Type | Seamless - Hot Rolled / Cold Drawn |

| A213 Alloy Steel Seamless Tubes Outer Diameter Size | A335 - 3/8" NB to 30" NB (Nominal Bore Size) |

| A213 Alloy Steel Seamless Tubes Wall Thickness | Schedule 20 to Schedule XXS (Heavier On Request) Up to 250 mm Thickness |

| A213 Alloy Steel Seamless Tubes Length | 5 to 7 Meters, 09 to 13 Meters, Single Random Length, Double Random Length And Customize Size. |

| A213 Alloy Steel Seamless Tubes Pipe Ends | Plain Ends / Beveled Ends / Coupling |

| A213 Alloy Steel Seamless Tubes Delivery Conditions | As Rolled, Cold Drawn, Normalizing Rolled, Thermomechanical Rolled / Formed, Normalizing Formed, Normalized and Tempered / Quenched and Tempered - BR / N / Q /T |

| A213 Alloy Steel Seamless Tubes Coating | Epoxy Coating / Colour Paint Coating / 3LPE Coating. |

| A213 Alloy Steel Seamless Tubes Other Testing | Tensile Test, Transverse Tension Tests, Flattening Test, Metal Structure and Etching Tests, Photomicrographs, Hardness Tests, etc. |

| A213 Alloy Steel Seamless Tubes Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM, ASME, API. |

| A213 Alloy Steel Seamless Tubes Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Galavanizing / Heat Treatment |

| A213 Alloy Steel Seamless Tubes Packaging | Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| A213 Alloy Steel Seamless Tubes Shipment & Transportation | By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes |

| A213 Alloy Steel Seamless Tubes Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

ASTM A213 Seamless Tubes

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

1.1 This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes, designated Grades T91, TP304, etc. These steels are listed in Tables 1 and 2.

1.2 Grades containing the letter, H, in their designation, have requirements different from those of similar grades not containing the letter, H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements.

1.3 The tubing sizes and thicknesses usually furnished to this specification are 1/8 in. [3.2 mm] in inside diameter to 5 in. [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness or, if specified in the order, average wall thickness. Tubing having other diameters may be furnished, provided such Tubes comply with all other requirements of this specification.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

TABLE 1 Chemical Composition Limits, %A, for Low Alloy SteelA Maximum, unless range or minimum is indicated. Where ellipses (…) appear in this table, there is no requirement, and analysis for the element need not be determined or reported.

B It is permissible to order T2 and T12 with a sulfur content of 0.045 max. See 16.3.

C Alternatively, in lieu of this ratio minimum, the material shall have a minimum hardness of 275 HV in the hardened condition, defined as after austenitizing and cooling to room temperature but prior to tempering. Hardness testing shall be performed at mid-thickness of the product. Hardness test frequency shall be two samples of product per heat treatment lot and the hardness testing results shall be reported on the material test report.

| Composition, % | |||||||||||||

| Grade | UNS Designation | Carbon | Manganese | Phosporus | Sulphur | Silicon | Nickel | Chromium | Molybdenum | Vanadium | Niobium | Aluminium | Other Elements |

| T5 | K41545 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 | … | 4.00-6.00 | 0.45-0.65 | … | |||

| T9 | K90941 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.03 | … | 1.00-1.50 | 0.90-1.10 | … | |||

| T11 | K11597 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | … | 1.00-1.50 | 0.44-0.65 | … | |||

| T22 | K21590 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 | … | 1.90-2.60 | 0.87-1.13 | … | |||

| T91 | K90901 | 0.07-0.14 | 0.30-0.60 | 0.02 | 0.010 | 0.20-0.50 | 0.4 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.06-0.10 | 0.02 | Ti 0.01 ZR 0.01 |

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

S1. STRESS-RELIVED ANNEALED Tubes

S2. STABILIZING HEAT TREATMENT

S3. UNSTRAIGHTENED Tubes

S4. INTERNGRANULAR CORROSION TEST

Send Inquiry to This Supplier

You May Also Like

-

ASTM A312/A213/A269 304/310/316/347/321 Stainless Steel Tube Ss Smls TubeUS$ 22 - 30MOQ: 100 Kilograms

-

ASTM A213 ASTM SA213 TP304 304L 316L 321 317L 310S 309S 2205 S31803 Seamless Stainless Steel Pipe TubeUS$ 22 - 30MOQ: 100 Kilograms

-

ASTM A213 Tp316L Stainless Steel Seamless Tube Pipe PriceNegotiableMOQ: 500 Kilograms

-

ASTM A213 Tp321 Seamless Stainless Steel Pipe TubeNegotiableMOQ: 500 Kilograms

-

ASTM A213 Tp321 Seamless Stainless Steel Pipe TubeUS$ 22 - 30MOQ: 100 Kilograms

-

Seamless Stainless Steel Pipe Tube ASTM A213/A213m ASTM A312/312m /JIS G3459 / DIN2462 /DIN17006 / DIN17007NegotiableMOQ: 2000 Kilograms

-

ASTM A213 Ss310s 310h 317 317L 321 321H 347 347H 904L Seamless Stainless Steel Pipes TubeNegotiableMOQ: 2000 Kilograms

-

ASTM A213 316L Seamless Stainless Steel TubeNegotiableMOQ: 500 Kilograms

-

Seamless Stainless Steel Pipe ASTM A213 316L Seamless Stainless Steel TubeNegotiableMOQ: 500 Kilograms

-

ASTM A213 Stainless Steel Seamless Tube/PipeUS$ 2200 - 3000MOQ: 500 Kilograms